Liquid-injection type online dynamic balance head structure for high rotating speed

A high-speed, liquid injection technology, applied in the field of dynamic balance, can solve the problems of small liquid injection time window, difficult precise control of intermittent liquid injection, splashing of liquid spray, etc., to reduce difficulty, eliminate the limitation of liquid injection time window, Effects that improve accuracy and balance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

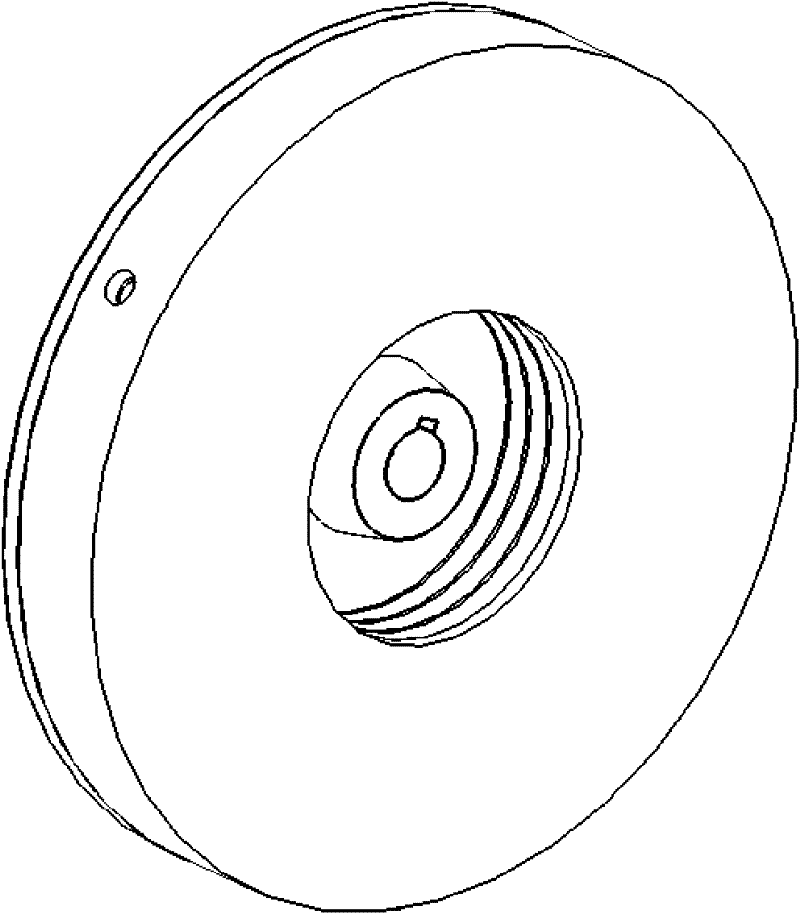

[0031] like figure 1 As shown, it is a structural schematic diagram of a liquid-injection online dynamic balancing head used in the case of high rotational speed according to the present invention.

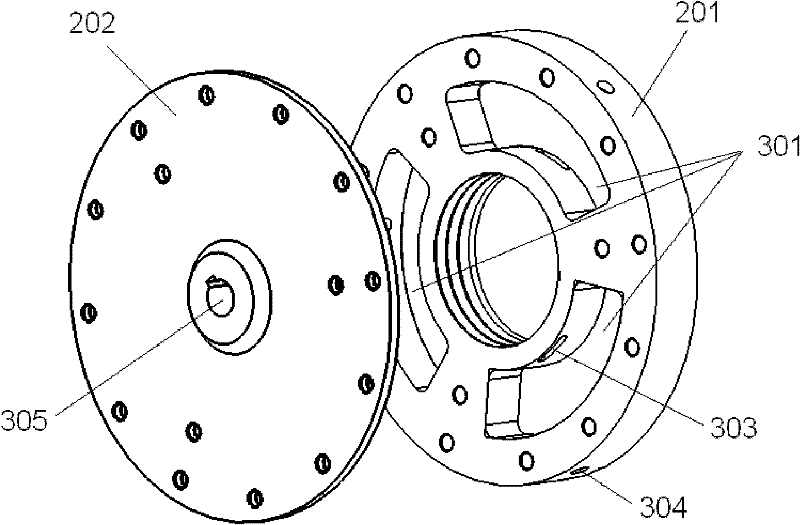

[0032] like figure 2 As shown, the structure of the liquid-injection online dynamic balancing head for high-rotation speed includes two parts: a chassis 202 and a sink plate 201 connected to the chassis 202 . A protruding liquid injection hole 305 is provided at the center of the chassis 202;

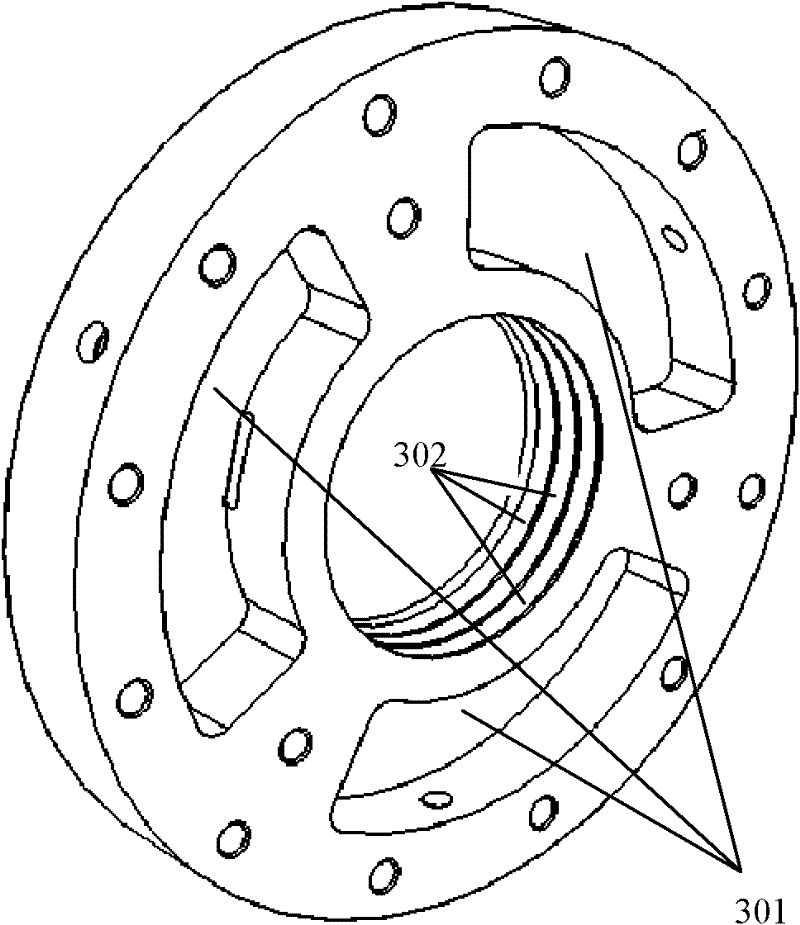

[0033] like image 3 As shown, it is a schematic structural diagram of a sink plate invented for a high-speed liquid-injection online dynamic balancing head structure. The structure of the sink plate 201 includes a central hole as shown in the figure. Three parallel annular grooves 302 are arranged on the inner side of the central hole wall of the sink plate 201. Three uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sector angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com