High-voltage and low-voltage compatible built-in brushless direct-current power generation system

A power generation system, low-voltage technology, applied in the direction of motor generator control, electromechanical devices, control systems, etc., can solve the problems of bulky, complex support equipment, manual disengagement of gas source vehicles, etc., to achieve simple operation and save the need for mechanical transmission device, the effect that is conducive to miniaturization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

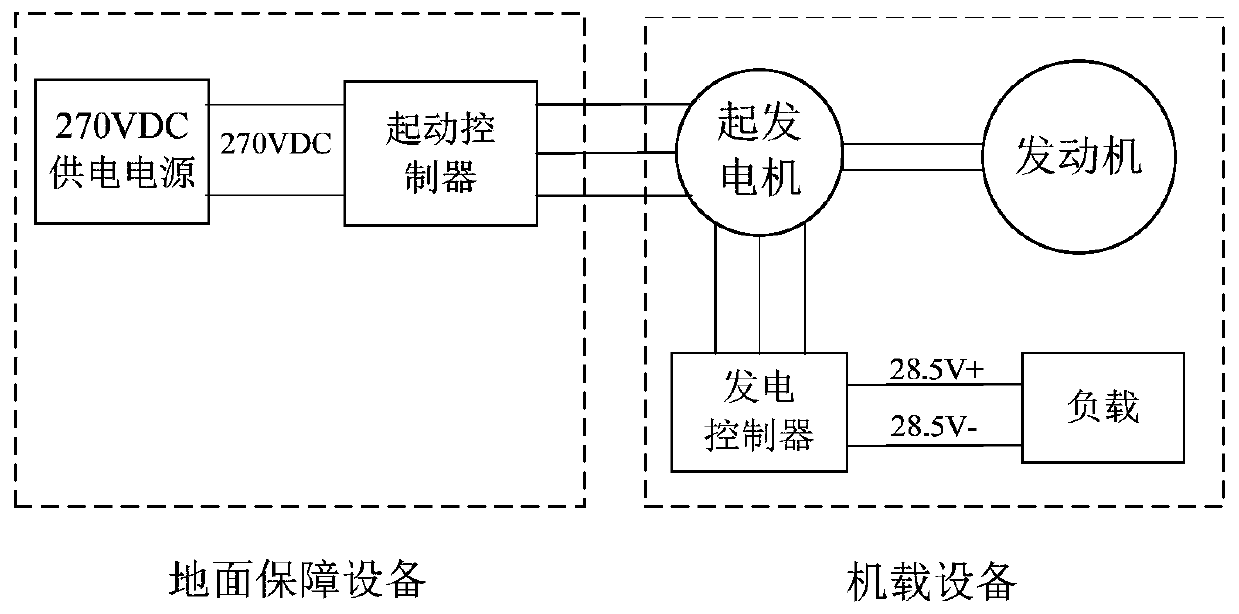

[0040] The present invention provides a high and low voltage compatible built-in brushless DC generator system, as attached figure 1 As shown, the system includes a brushless generator, a starter controller, a generator controller and connecting cables.

[0041] The function of the high and low voltage compatible built-in brushless generator system is to use 270VDC high-voltage power supply during the engine starting stage. The starter controller drags the engine to the ignition speed in the working state of the motor. After the engine motor is ignited, the brushless generator continues to assist After the engine reaches a certain speed and the engine is working, the brushless generator will switch to the working state of the generator, and the power generation controller will convert the mechanical energy of the high-voltage rotor of the engine into elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com