Piston type self-balancing oil-water substitution oil storage tank

A self-balancing, piston-type technology, applied in ships, some cabins in the hull, and reducing ship motion through displacement, can solve the problems of complex fuel tank systems, large mutual pollution between fuel and sea water, and insufficient system self-balancing. The effect of high balance accuracy, saving layout space and simplifying equipment composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

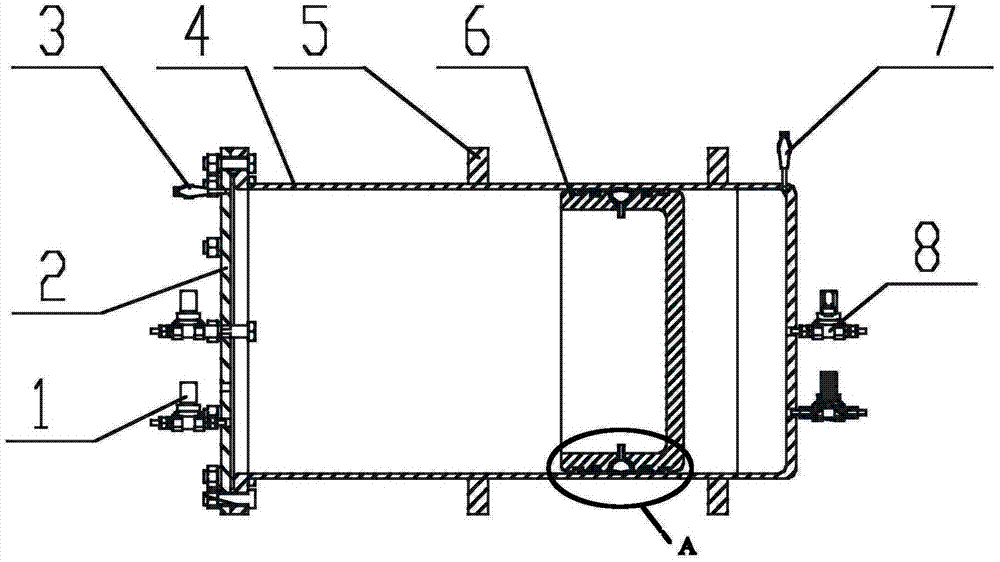

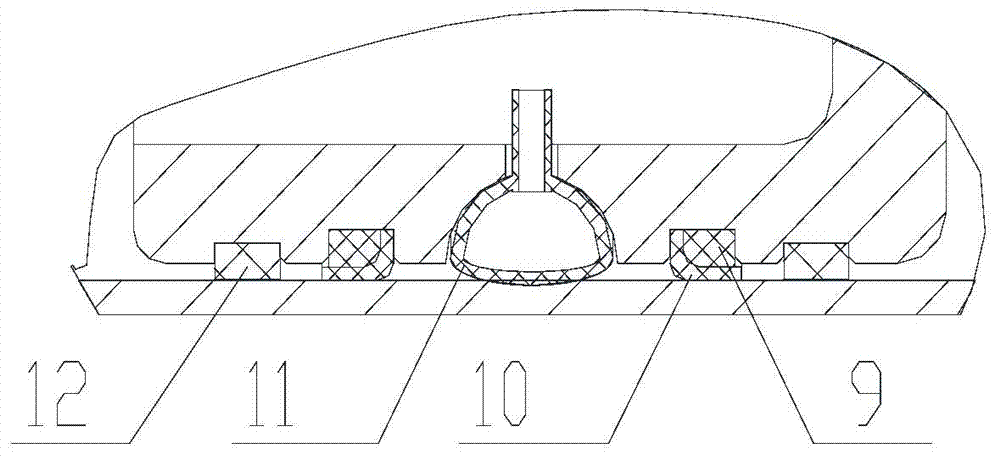

[0018] figure 1 Shown is a schematic structural view of the piston-type self-balancing oil-water replacement oil storage tank of the present invention. The oil storage tank is mainly composed of tank body 4, isolation device 6, head 2, reinforcement ring 5, oil storage side valve group 1, replacement water side valve group 8, air release valve 3 arranged on the side of the oil storage tank, arrangement It is composed of equipment such as the air release valve 7 on the water side of the replacement cabin. The tank body 4 divides the oil storage tank into two independent storage spaces that can be changed in real time through an isolation device 6, that is, the oil storage tank and the replacement water tank. A mechanical seal is set between the isolation device 6 and the inner wall of the tank body 4 Components for isolating fuel and displacing water.

[0019] The tank body 4 is a cylindrical structure, and the cross section is generally circular, and can also be oval, semici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com