One disc flexible rotor transient equilibration process

A flexible rotor, transient balancing technology, applied in static/dynamic balance testing, measuring devices, instruments, etc., can solve the problems of long time, many startups, complicated procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described now in conjunction with accompanying drawing:

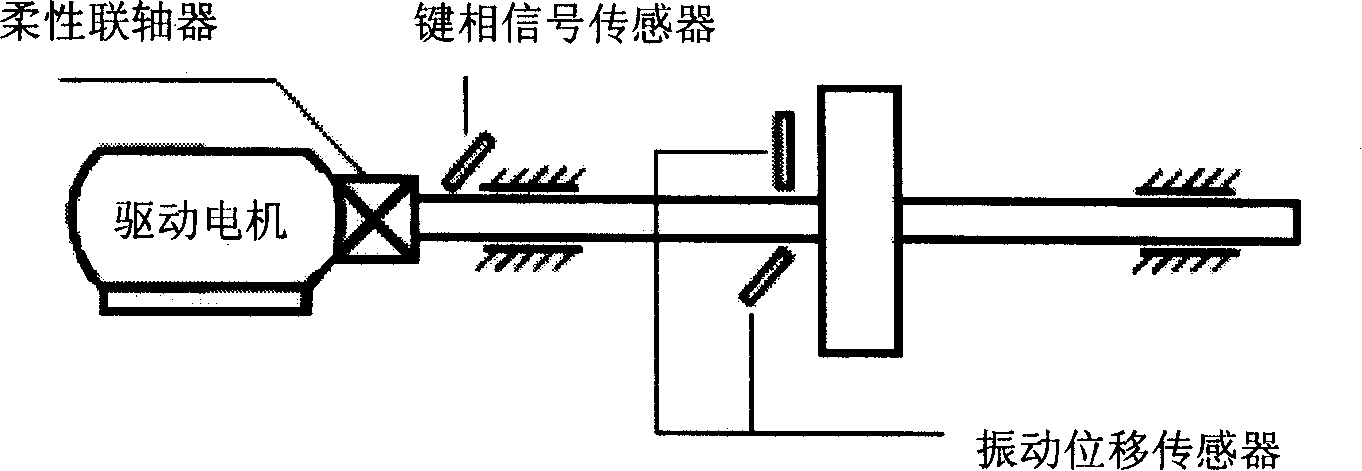

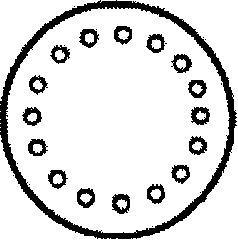

[0036] The present embodiment is in the RK4 rotor test bench of Bently Company (reference figure 1 ) completed on. The characteristic disk of the rotor is a steel disk of equal thickness with 16 holes (refer to figure 2 ), the distance from the center of each hole to the rotor shaft is 3cm. On the one hand, the 16 holes are used to set the initial unbalance of the rotor, and on the other hand, they are used to add test weight when balancing the rotor. The rotor system is equipped with a number of balance screws ranging in weight from 0.1g to 2g.

[0037] The parameters of the rotor system are as follows:

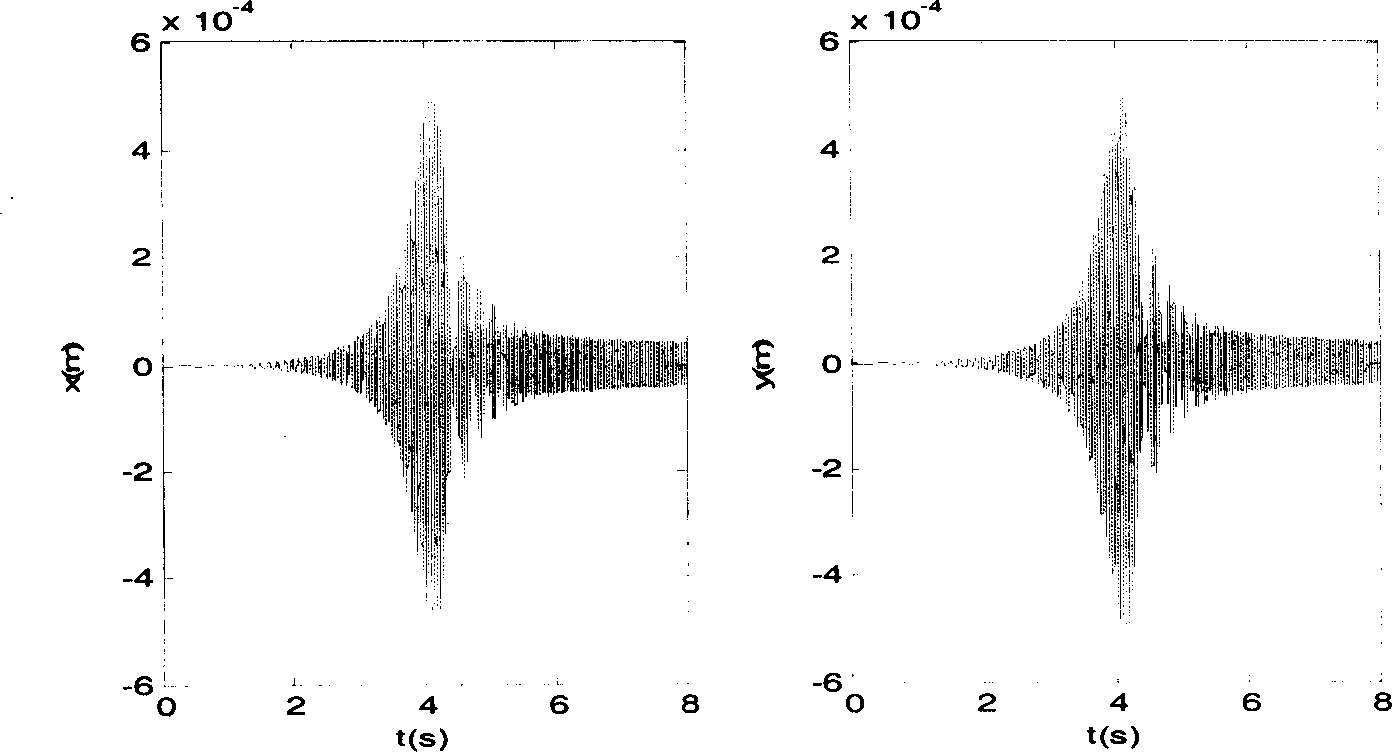

[0038] The total length of the shaft l = 0.56m, each end of the bearing housing protrudes l 1 = l 2 =0.03m, the diameter of the shaft d=10mm, the density of the shaft is ρ=7.8×10 3 kg / m 3 , the mass of the disk is m=0.8kg, and the diameter D=75mm. The maximum spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com