Tyre-disassembling and balancing integrated machin

An all-in-one, balanced technology, applied in static/dynamic balance testing, tire installation, tire parts, etc., can solve the problems of heavy tires, troublesome, difficult to move, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

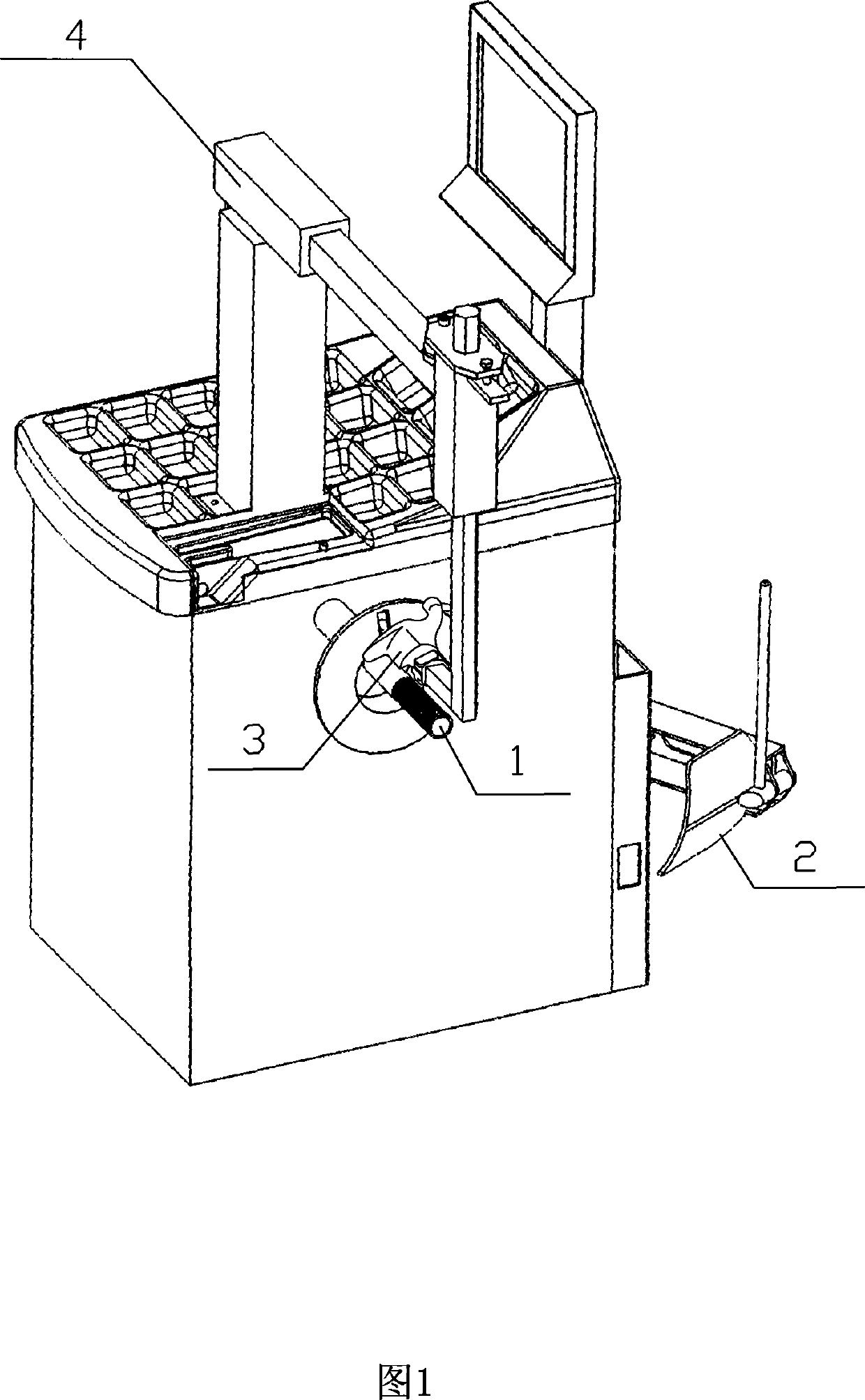

[0022] Implementation mode one: if figure 1 As shown, the all-in-one tire removal and balance machine includes a tire installation shaft 1, a balance drive mechanism, a balance detection system, a tire bead shovel 2 and corresponding accessories, and is characterized in that it also includes a beak 3 and a tire removal / installation drive mechanism. The mouth 3 is installed on the telescopic frame 4, and the telescopic frame 4 includes at least two telescopic arms perpendicular to each other, one of which is parallel to the tire installation axis 1, and the axis line of the bird's beak 3 and the axis line of the tire installation axis 1 Parallel; a clutch device is provided between the tire removal / installation drive mechanism and the tire installation shaft 1, and under the control of the clutch device, the tire installation shaft 1 can switch between the two drive mechanisms.

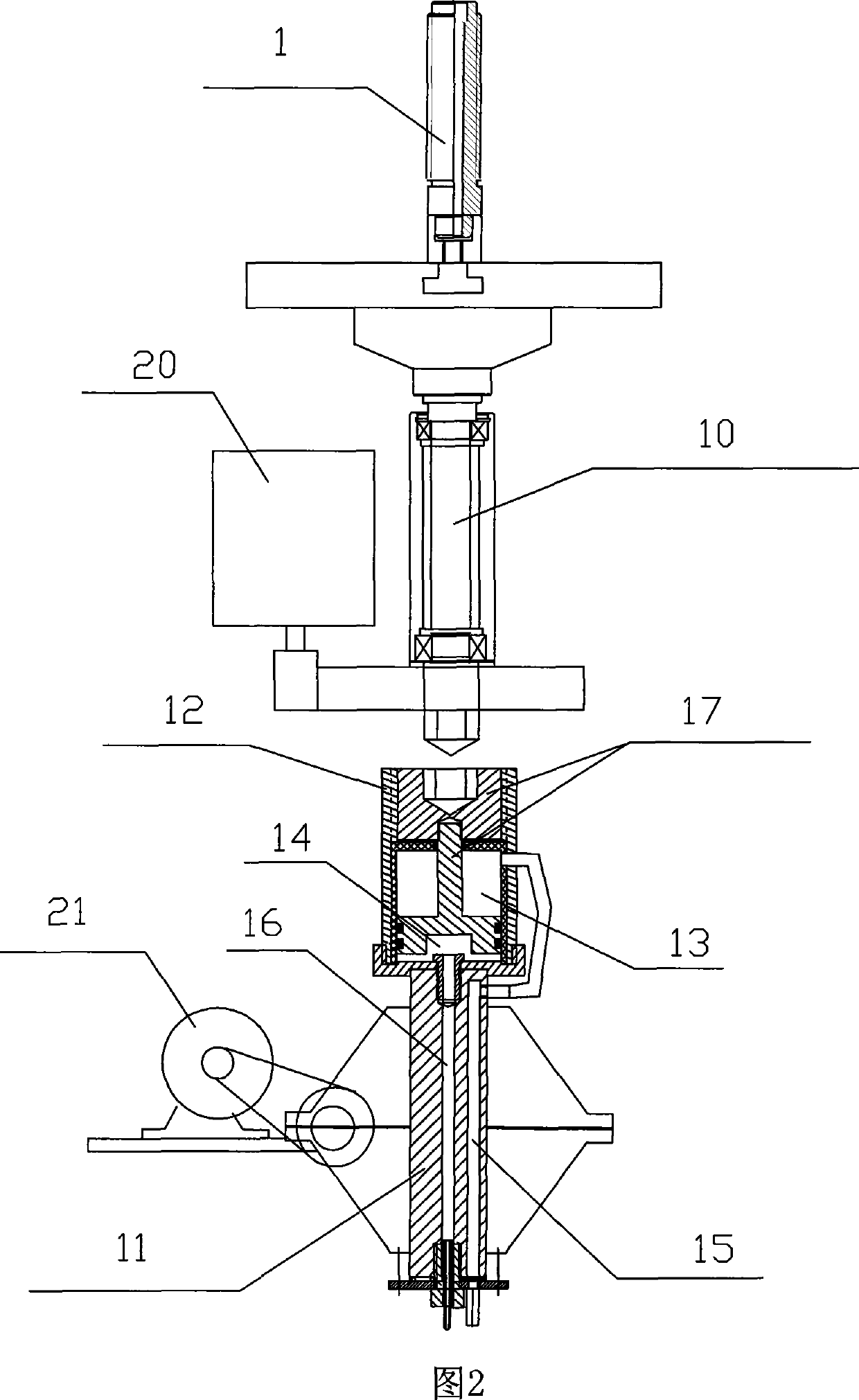

[0023] Such as figure 2 As shown, the clutch device includes a front axle 10 and a rear axle 11, ...

Embodiment approach 2

[0025] Implementation mode two: if Figure 6-8 As shown: the balance driving mechanism and its tire installation shaft 1 are arranged on a box body 18, which is hinged on the base, and a control cylinder 19 is arranged between it and the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com