Weakly supervised casting defect recognition method based on attention mechanism

A technology for casting defects and identification methods, applied in image data processing, instruments, analysis materials, etc., can solve the problems of complex algorithm and threshold parameter adjustment, labor consumption, increase production costs, etc., to ensure defect recognition rate and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

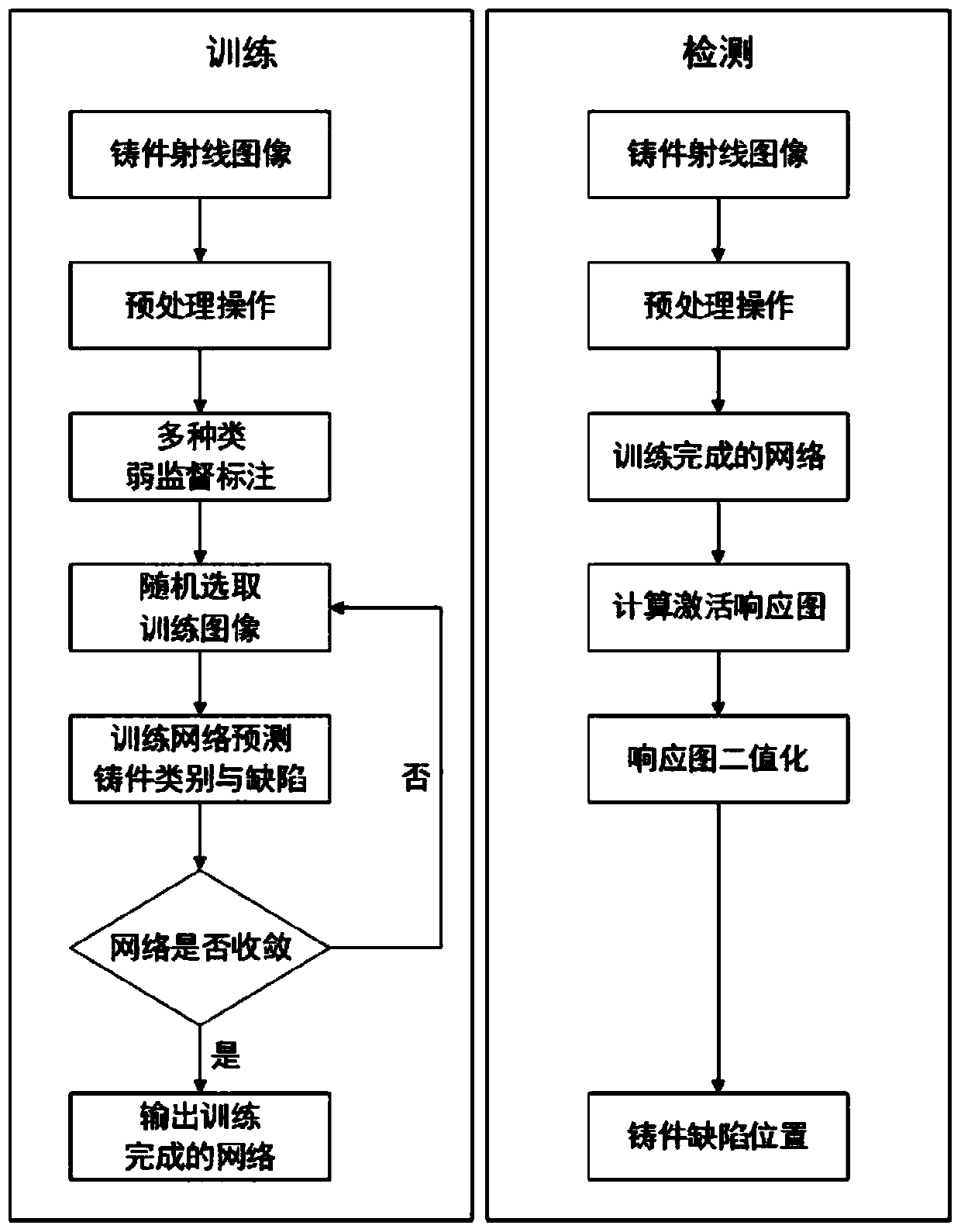

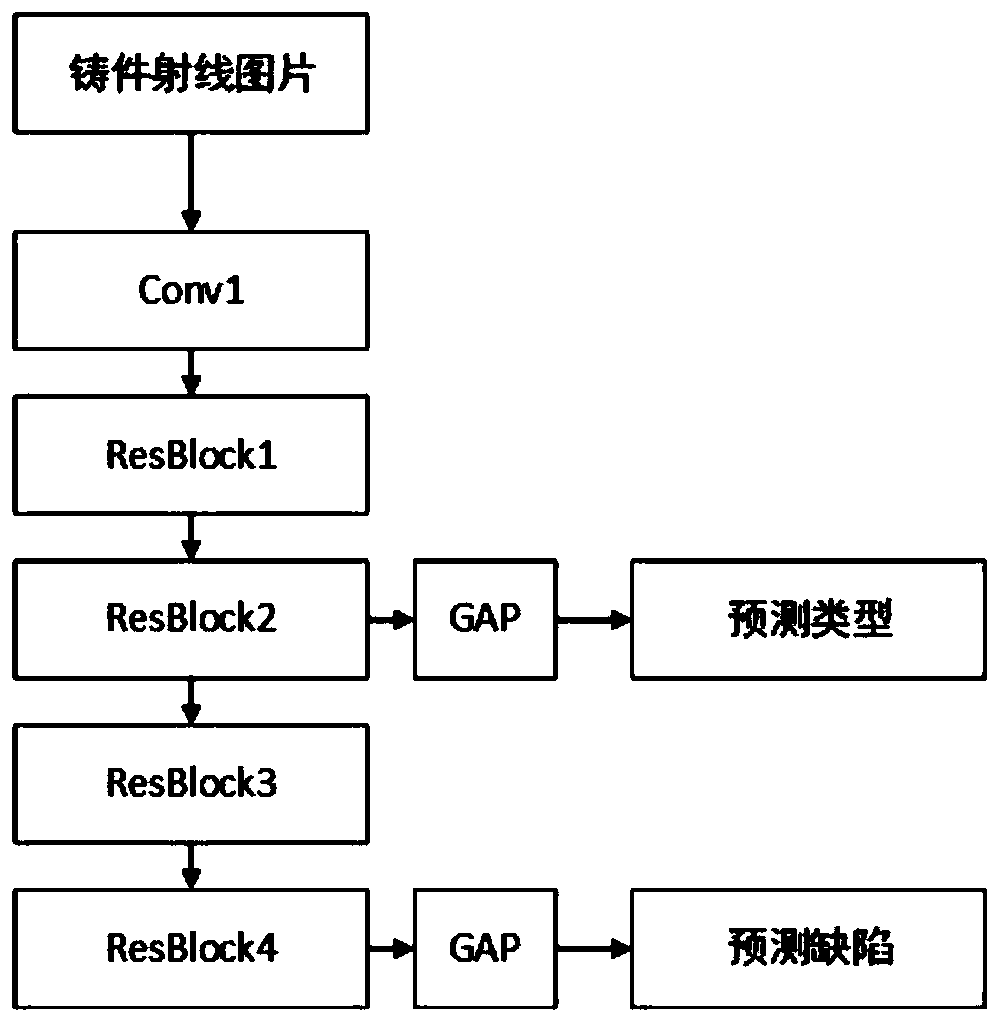

[0025] Such as figure 1 The flow chart of the weakly supervised casting defect recognition method based on the attention mechanism is shown, and the method is as follows:

[0026] 1. For each acquired casting radiographic image ( figure 2 ), perform image scale normalization and color channel expansion preprocessing, and then perform multi-label weak labeling. The implementation is as follows:

[0027] 1.1. Scale each casting ray image to 512*512, and use bilinear interpolation for vacant pixels to complete the image scale normalization process;

[0028] 1.2. Extend the color channel of the image after image scale normalization processing. The expansion method is to copy the original value, and the number of channels after expansion is 3;

[0029] 1.3. Multi-type weak annotations are performed on all preprocessed images to obtain a set of all image annotations Where n is the total number of images, that is, each image also contains the type label y t and defect label y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com