Precision-investment casting method of titanium aluminum base alloy aircraft engine blade

A technology for investment precision casting and aircraft engine, which is applied in the field of investment precision casting of titanium-aluminum-based alloy aircraft engine blades, can solve the problems of complex processing procedures, low processing efficiency, deformation, etc., and achieves simple procedures, high processing efficiency, The effect of reducing the number of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

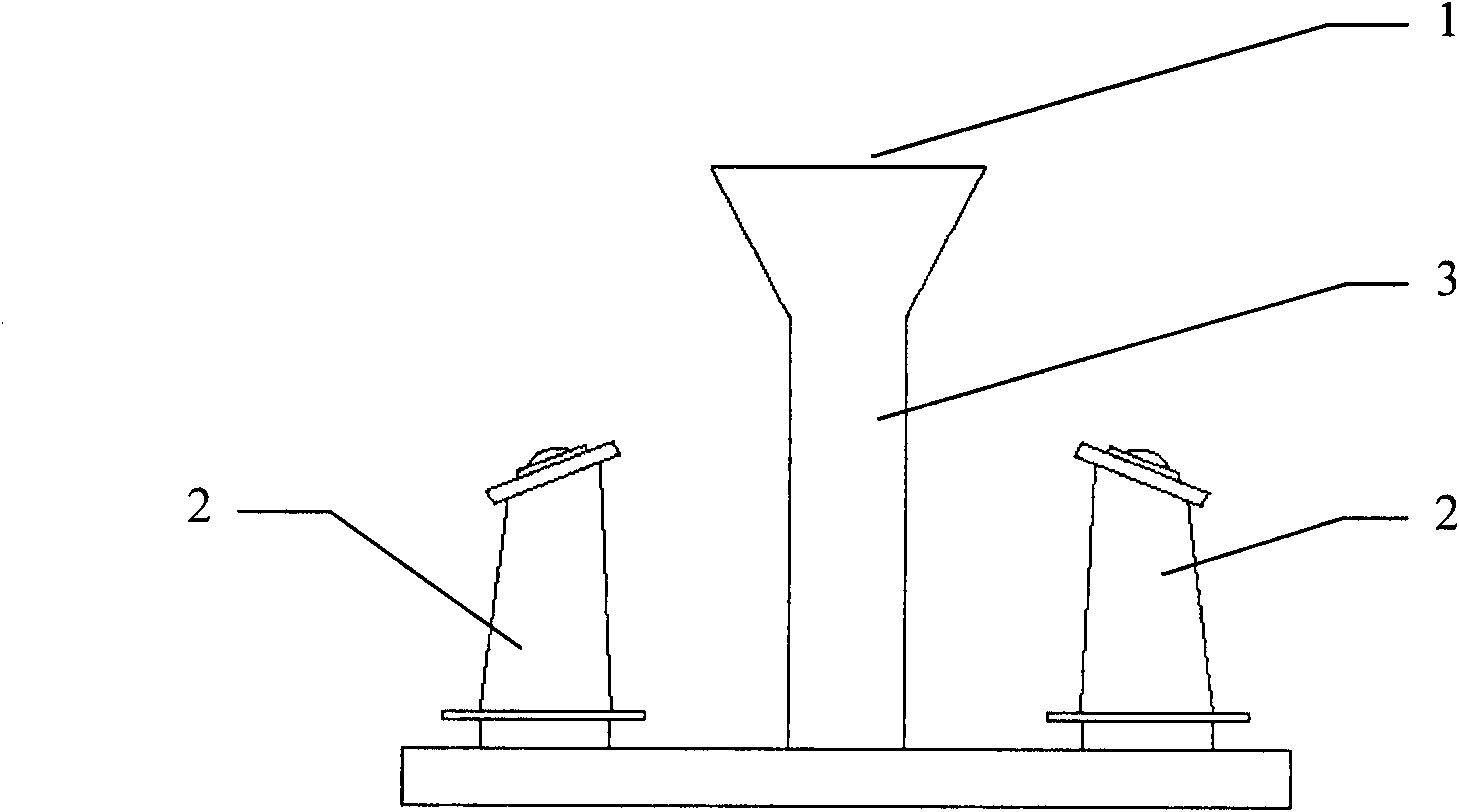

[0016] The investment casting method for titanium-aluminum-based alloy aircraft engine blades described in this embodiment adopts a water-cooled copper crucible vacuum induction melting centrifugal casting method, and the specific process is as follows:

[0017] Put the raw material to be smelted into the vacuum chamber of the water-cooled copper crucible;

[0018] Use argon to flush the melting chamber of the water-cooled copper crucible, and evacuate the vacuum chamber of the water-cooled copper crucible to 10 ~5 mbar~10 ~2 mbar, then filled with argon to 5.50mbar ~ 13mbar, and then vacuumed to 10 ~5 mbar~10 ~2 mbar, so repeated 2 to 6 times, and finally keep the vacuum degree in the smelting chamber of the water-cooled copper crucible at 10 ~5 mbar~10 ~2 Between mbar;

[0019] The raw materials in the water-cooled copper crucible are smelted in a water-cooled copper crucible induction melting furnace with a melting power of 330kW-350kW. After the smelting is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com