Low-density corrosion-resistant steel and preparation method and application thereof

A corrosion-resistant steel, low-density technology, used in transportation and packaging, hull decks, ship construction, etc., can solve the problems of difficult to achieve corrosion resistance of stainless steel and harsh service environment of stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

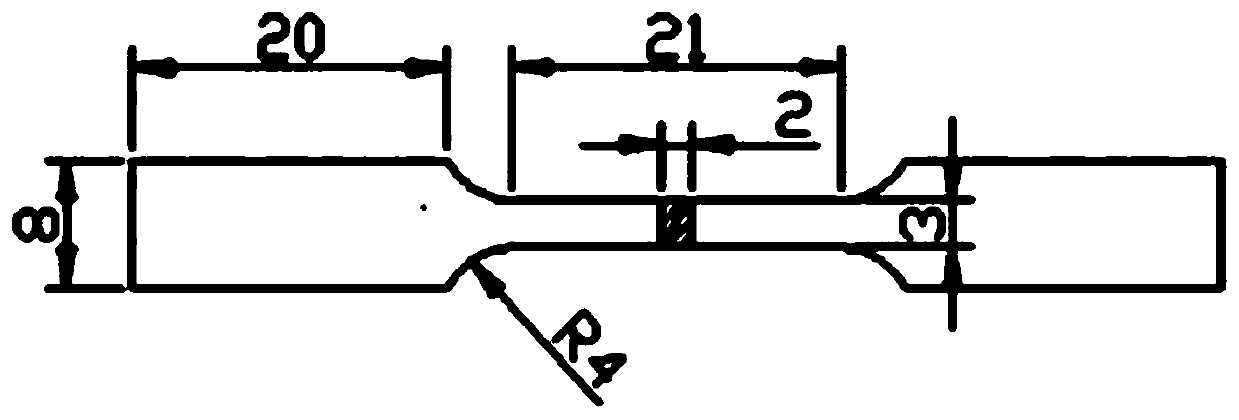

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing low-density corrosion-resistant steel described in the above technical solution, comprising the following steps:

[0037] 1) Smelting the raw material of low-density corrosion-resistant steel to obtain alloy ingots

[0038] 2) hot forging the alloy ingot to obtain alloy forging material;

[0039] 3) subjecting the alloy forging to water-toughening treatment to obtain a water-tough alloy forging;

[0040] 4) performing hot rolling treatment and solid solution treatment on the water-tough alloy forging material in turn to obtain an alloy slab;

[0041] 5) cold-rolling the alloy slab to obtain a cold-rolled alloy slab;

[0042] 6) Perform aging treatment on the cold-rolled alloy slab to obtain low-density corrosion-resistant steel.

[0043] The invention melts the raw material of the low-density corrosion-resistant steel to obtain the alloy ingot. In the present invention, the raw material of the high-strength ...

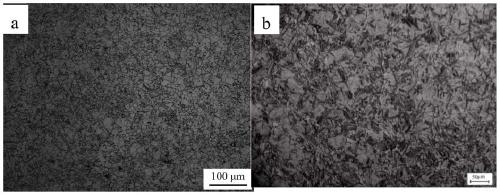

Embodiment 1

[0067] In terms of mass percentage, 0.6% carbon, 28% manganese, 8% aluminum rod with a diameter of 25mm, 0.2% silicon, 0.5% chromium, 0.1% vanadium, and 0.1% molybdenum, and the balance is an iron rod with a diameter of 25mm.

[0068] After the above raw materials are ultrasonically cleaned in acetone and alcohol, the aluminum, manganese, iron and silicon in the raw materials are placed in a magnesia crucible in a vacuum induction furnace, and the vanadium, chromium, carbon and molybdenum in the raw materials are placed In the secondary feeding hopper of the vacuum induction furnace; evacuate the vacuum induction furnace to a vacuum of 0.02MPa, then fill the vacuum induction furnace with high-purity argon to a vacuum of 0.03MPa; set the power of the vacuum induction furnace to 5kW, heating 5min; the power of the vacuum induction furnace is set to 10kW, heating 5min; the power of the vacuum induction furnace is set to 20kW, and after heating for 10min, pour the raw materials in ...

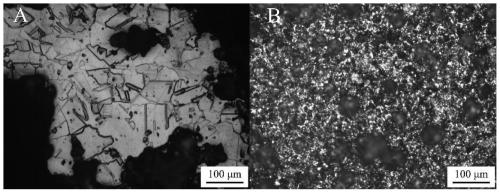

Embodiment 2

[0075] In terms of mass percentage, 0.9% carbon, 30% manganese, 10% aluminum rod with a diameter of 25mm, 0.3% silicon, 1.5% chromium, 0.4% vanadium, 0.5% molybdenum, and the balance is an iron rod with a diameter of 25mm.

[0076]After the above raw materials are ultrasonically cleaned in acetone and alcohol, the aluminum, manganese, iron and silicon in the raw materials are placed in a magnesia crucible in a vacuum induction furnace, and the vanadium, chromium, carbon and molybdenum in the raw materials are placed In the secondary feeding hopper of the vacuum induction furnace; evacuate the vacuum induction furnace to a vacuum of 0.02MPa, then fill the vacuum induction furnace with high-purity argon to a vacuum of 0.04MPa; set the power of the vacuum induction furnace to 5kW, heating 6min; the power of the vacuum induction furnace is set to 10kW, heating 6min; the power of the vacuum induction furnace is set to 20kW, and after heating for 12min, pour the raw materials in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com