Food suitable for obese and overweight people and making method thereof and weight and health management method

A technology for obesity, overweight and food, applied in food preparation, food ingredients, applications, etc., can solve the problems of insignificant effect and slow effect, and achieve the effect of improving health status, improving health status, and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1. The ingredient ratio of this nutritional food is as follows (wt%): 35% of soybean protein isolate puffed granules, 20% of maltitol liquid, 4% of wheat protein, 4% of pea protein, 10% of resistant dextrin, and 5% of citrus fiber , 5% of gamma-aminobutyric acid, 5% of macadamia nuts, 3% of hazelnuts, 2% of quick-frozen blueberries, 2% of passion fruit, 2% of edible glycerin, and 3% of vegetable oil.

[0064] 2. The manufacturing process of the nutritious food comprises the following steps:

[0065] 1) Weigh various raw materials according to the ratio;

[0066] 2) Boil the syrup, heat the maltitol to 105°C in an electric heating oil pan, keep it warm, and set it aside.

[0067] 3) Ingredients, according to the following classification ingredients:

[0068] Various powdery raw materials: wheat protein, pea protein, resistant dextrin, citrus fiber, γ-aminobutyric acid;

[0069] Granule raw materials: soybean protein isolate puffed granules, quick-frozen blueberry gran...

Embodiment 2

[0078] 1. The ingredient ratio of this nutritional food is as follows (wt%): 38% of soybean protein isolate puffed granules, 23% of maltitol liquid, 5% of wheat protein, 3% of pea protein, 9% of resistant dextrin, and 3% of citrus fiber , Yeast Glucan 3%, Macadamia Nut 6%. Hazelnut 3%, quick-frozen blueberry grain 2%, edible glycerin 2%, vegetable oil 3%.

[0079] 2. The manufacturing process of the nutritious food comprises the following steps:

[0080] 1) Weigh various raw materials according to the ratio;

[0081] 2) Boil the syrup, heat the maltitol to 105°C in an electric heating oil pan, keep it warm, and set it aside.

[0082] 3) Ingredients, according to the following classification ingredients:

[0083] Various powdery raw materials: wheat protein, pea protein, resistant dextrin, citrus fiber, γ-aminobutyric acid;

[0084] Granule raw materials: soybean protein isolate puffed granules, quick-frozen blueberry granules, macadamia nuts, hazelnuts, passion fruit;

[...

Embodiment 3

[0093] The ingredient ratio of the nutritional food is as follows (wt%): 30% soybean protein isolate, 10% barley puffed granules, 25% sorbitol, 5% resistant dextrin, 3% citrus fiber, 2% yeast dextran, γ-aminobutyric acid 1%, hazelnut 8%, pistachio 5%, quick-frozen raspberry 2%, quick-frozen passion fruit 3%, edible glycerin 5%, vegetable oil 1%.

[0094] The manufacturing process of this nutritious food is basically the same as that of Examples 1 and 2.

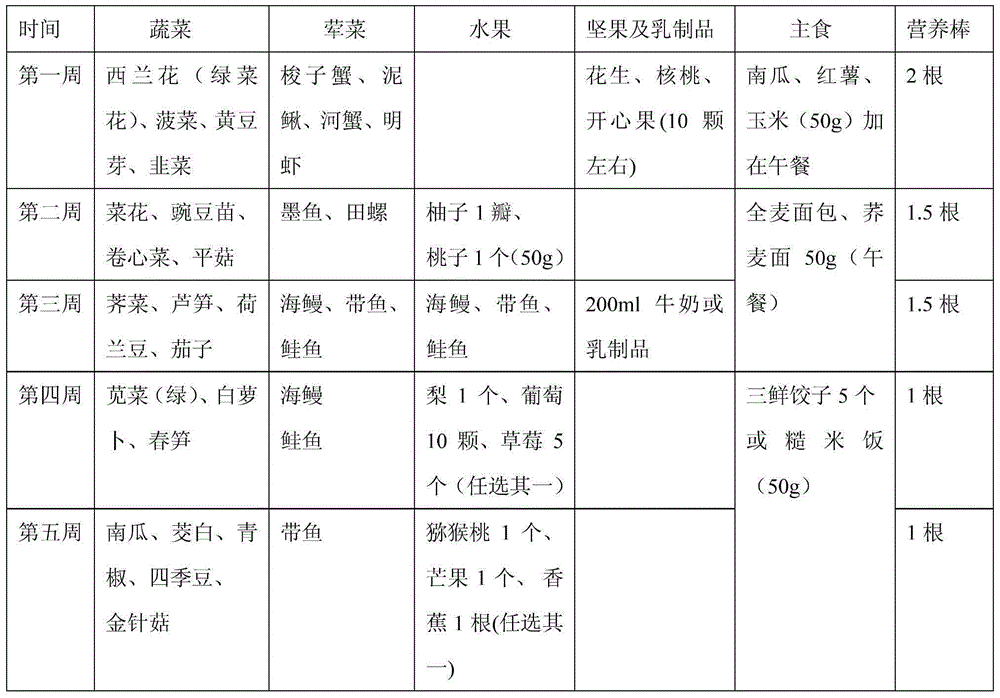

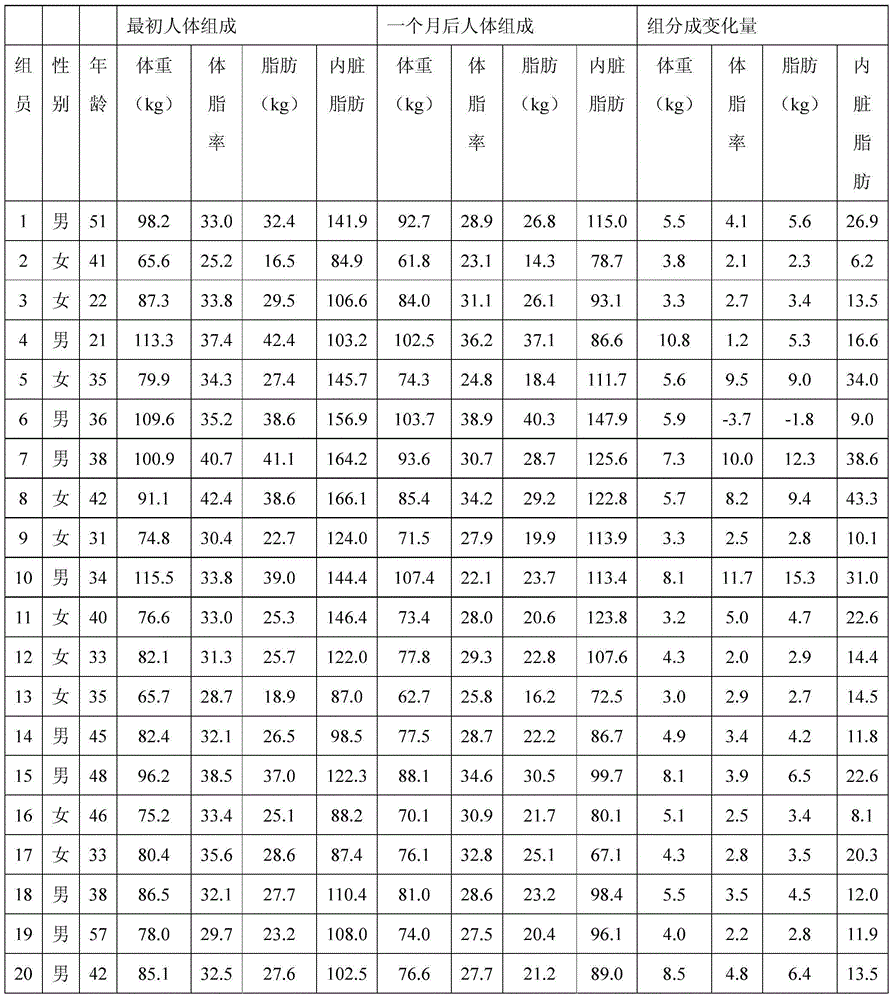

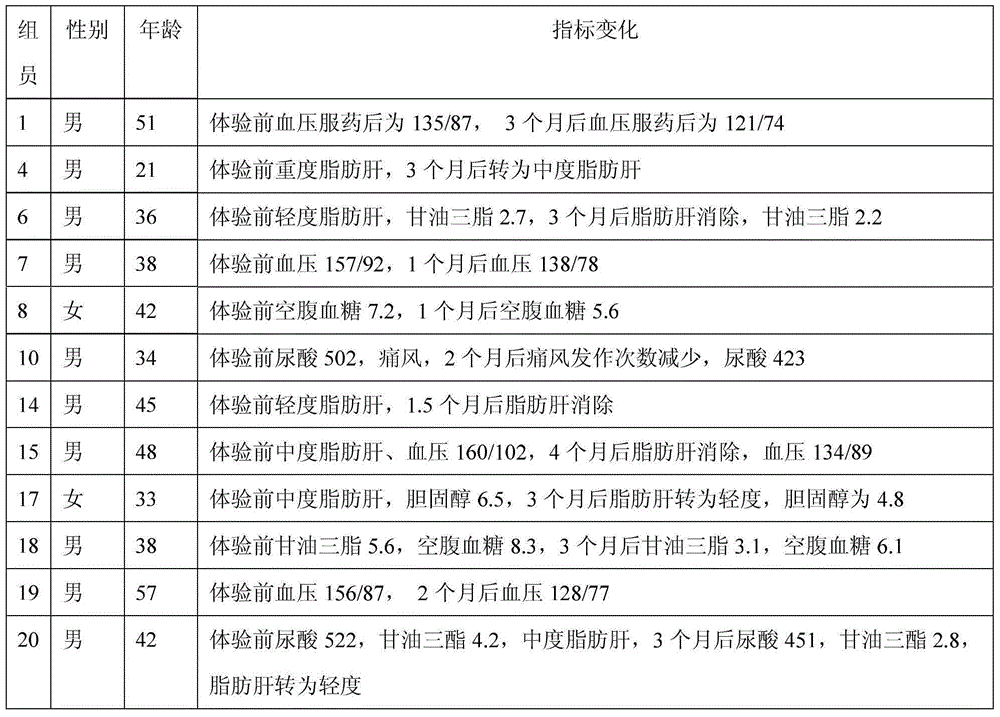

[0095] The efficacy of the nutritious food obtained in Examples 1-3 will be described as follows. Incidentally, because the nutritional food obtained in Examples 1-3 is in the form of a bar (also can be regarded as a bar), it is named "nutrition bar" as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com