Preparation method of aluminum-based composite material

A technology of aluminum-based composite materials and aluminum alloys, which is applied in the field of preparation of aluminum-based composite materials, can solve problems such as difficult to obtain, improve the performance of the interface between silicon carbide particles and aluminum alloy matrix, and reduce complexity, so as to reduce energy consumption and eliminate casting The effect of improving the mechanical properties of product defects and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

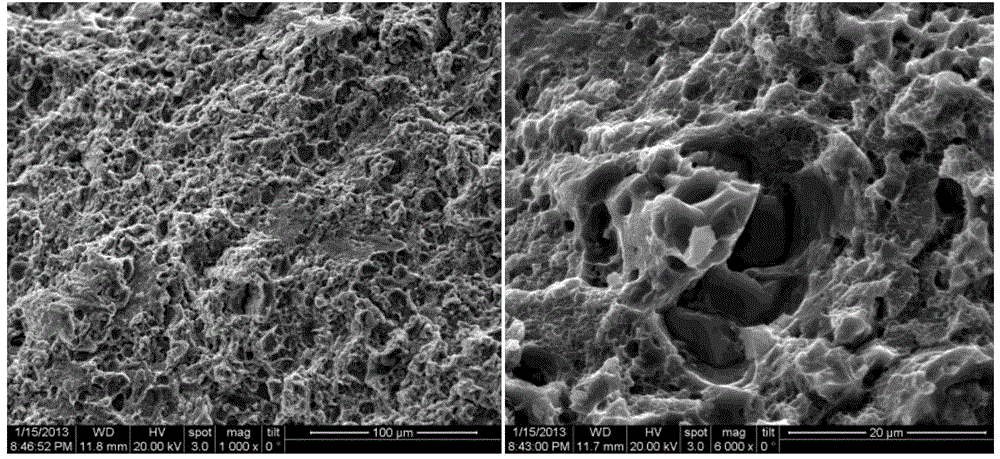

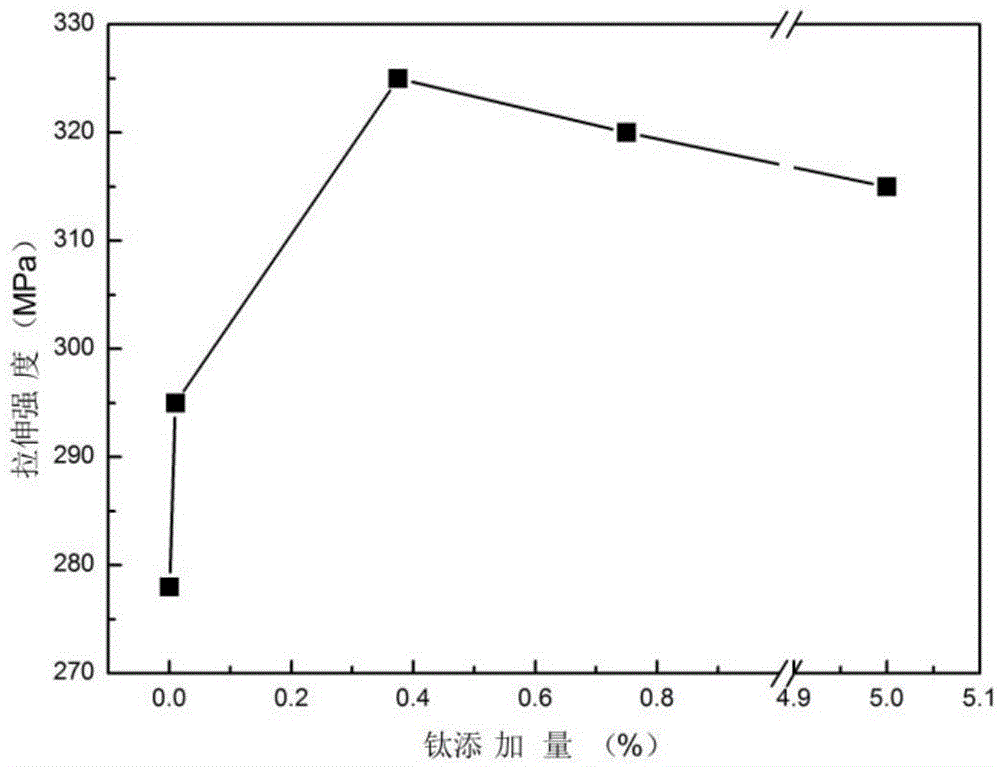

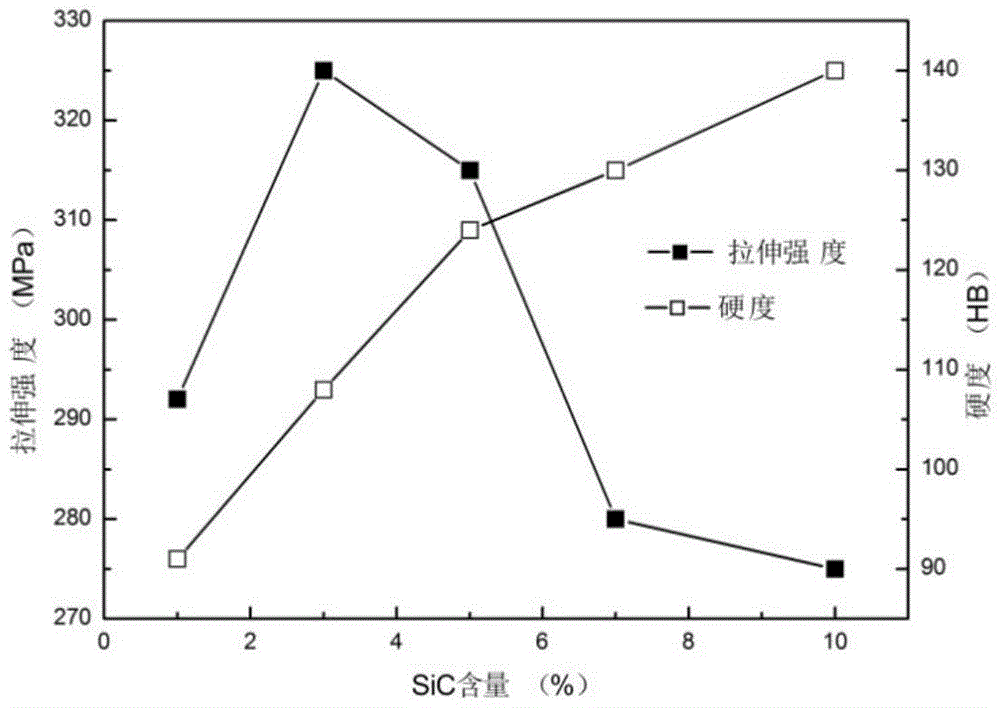

[0030] First, melt the 2024 (Al-Cu-Mg) aluminum alloy ingot and heat it to 750°C, add titanium-containing additives and stir at a constant temperature for 15 minutes to obtain composite aluminum alloy melt A. The amount of titanium added in the titanium-containing additive is 0.375wt% of the alloy melt A; after degassing and slag removal, the obtained composite aluminum alloy melt A was rapidly cooled to a semi-solid state of 620°C, and the preheated at 250°C was oxidized at 1000°C for 2 hours under stirring. The treated SiC powder was added to the composite aluminum alloy melt A, stirred at 200rpm for 15min to obtain the composite aluminum alloy melt B, the amount of SiC powder was 3wt% of the composite aluminum alloy melt B; the composite aluminum alloy melt Body B was heated to 760°C, and stirred at a stirring speed of 450 rpm for 30 minutes to obtain a uniformly mixed composite aluminum alloy melt B; then, the uniformly mixed composite aluminum alloy melt B was cast into a ...

Embodiment 2

[0032] The difference between this example and Example 1 is that the amount of titanium added in the titanium-containing additive is 0.01 wt% of the composite aluminum alloy melt A.

Embodiment 3

[0034] The difference between this example and Example 1 is that the amount of titanium added in the titanium-containing additive is 0.75wt% of the composite aluminum alloy melt A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com