Integrally cast type mould plate trolley and construction method of concrete pouring of underground passage

A technology for formwork trolleys and underground passages, which is applied in underground chambers, earthwork drilling, tunnels, etc., can solve the problems of large occupation of temporary construction sites, long construction periods, and high safety risks, reducing the amount of manual work, The effect of improving construction efficiency and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

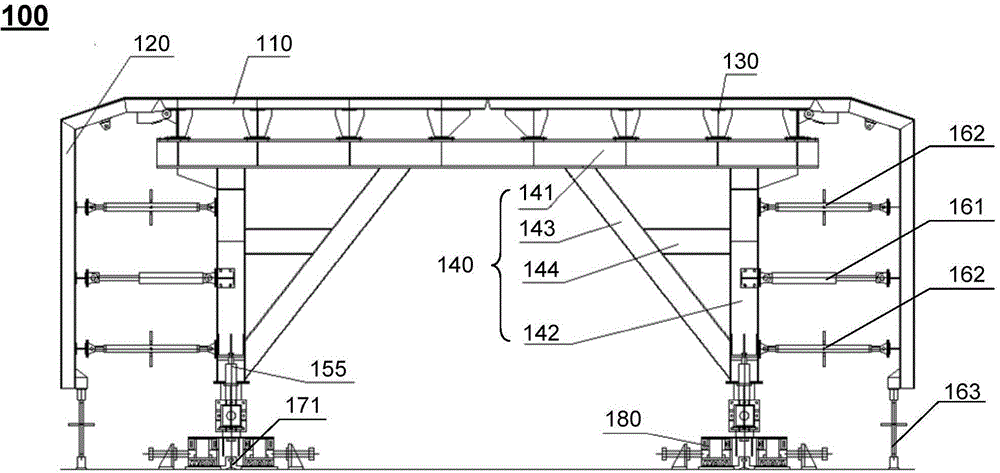

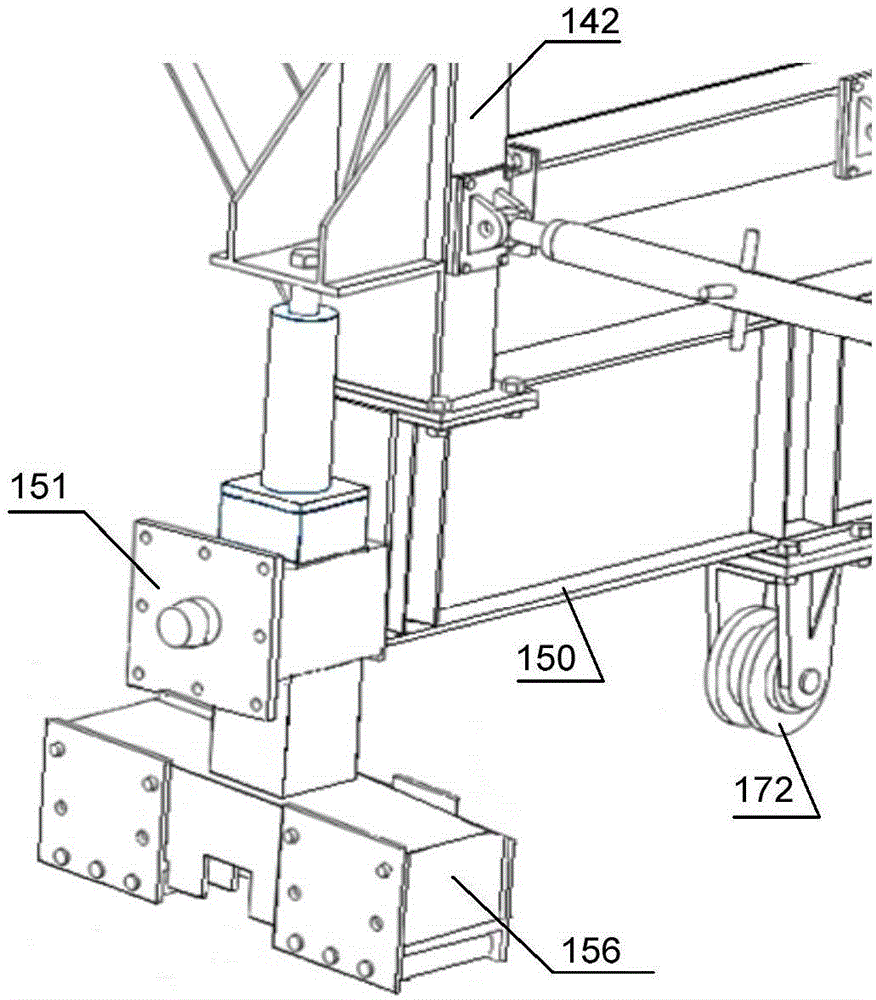

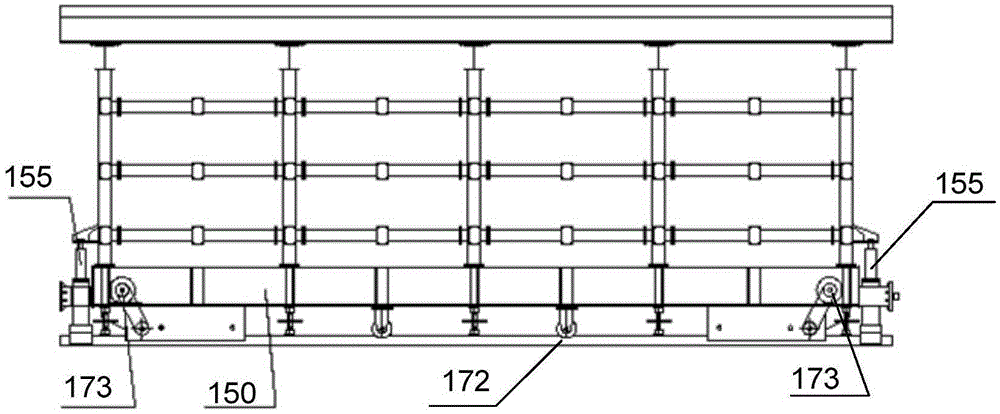

[0033] Please refer to figure 1 , which is the front view of the integrated pouring formwork trolley according to Embodiment 1 of the present invention. Such as figure 1 As shown, the integrated pouring formwork trolley is used for the concrete pouring construction work of the underground passage, and the integral pouring formwork trolley 100 has at least one trolley unit, and the trolley unit includes: a formwork, a longitudinal beam 130, a door Frame 140, underframe platform 150, vertical elevating device and lateral demoulding support formwork device; Described formwork comprises top formwork 110 and side formwork 120, and described side formwork 120 is positioned at the both sides of described top formwork 110 and passes pin The shaft is hinged with the top template 110; the top template 110 is supported on the door frame 140 through the longitudinal beam 130, and the door frame 140 is installed on the bottom frame platform 150; the vertical lifting device and The door f...

Embodiment 2

[0065] Please refer to Figure 6 and Figure 7 , which is a schematic structural view of the integrated pouring formwork trolley according to Embodiment 2 of the present invention. Such as Figure 6 and Figure 7As shown, the integrated pouring formwork trolley 200 is used for the concrete pouring construction work of the underground passage, and the integral pouring formwork trolley 200 has at least one trolley unit, and the trolley unit includes: a template, a longitudinal beam 130, Door frame 140, underframe platform 150, walking device, vertical lifting device and lateral demoulding support formwork device; Described formwork comprises top formwork 110 and side formwork 120, and described side formwork 120 is positioned at two sides of described top formwork 110 side and is hinged with the top template 110 through a pin; the top template 110 is supported on the door frame 140 through the longitudinal beam 130, and the door frame 140 and the vertical lifting device are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com