Liquid nitrogen pump power end assembly

A power end and liquid nitrogen pump technology, which is applied to liquid fuel engines, pumps, pump components, etc., can solve the problems of being unable to connect with foreign liquid power ends and supporting connections, and achieves easy processing and manufacturing, prolonging service life, and simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

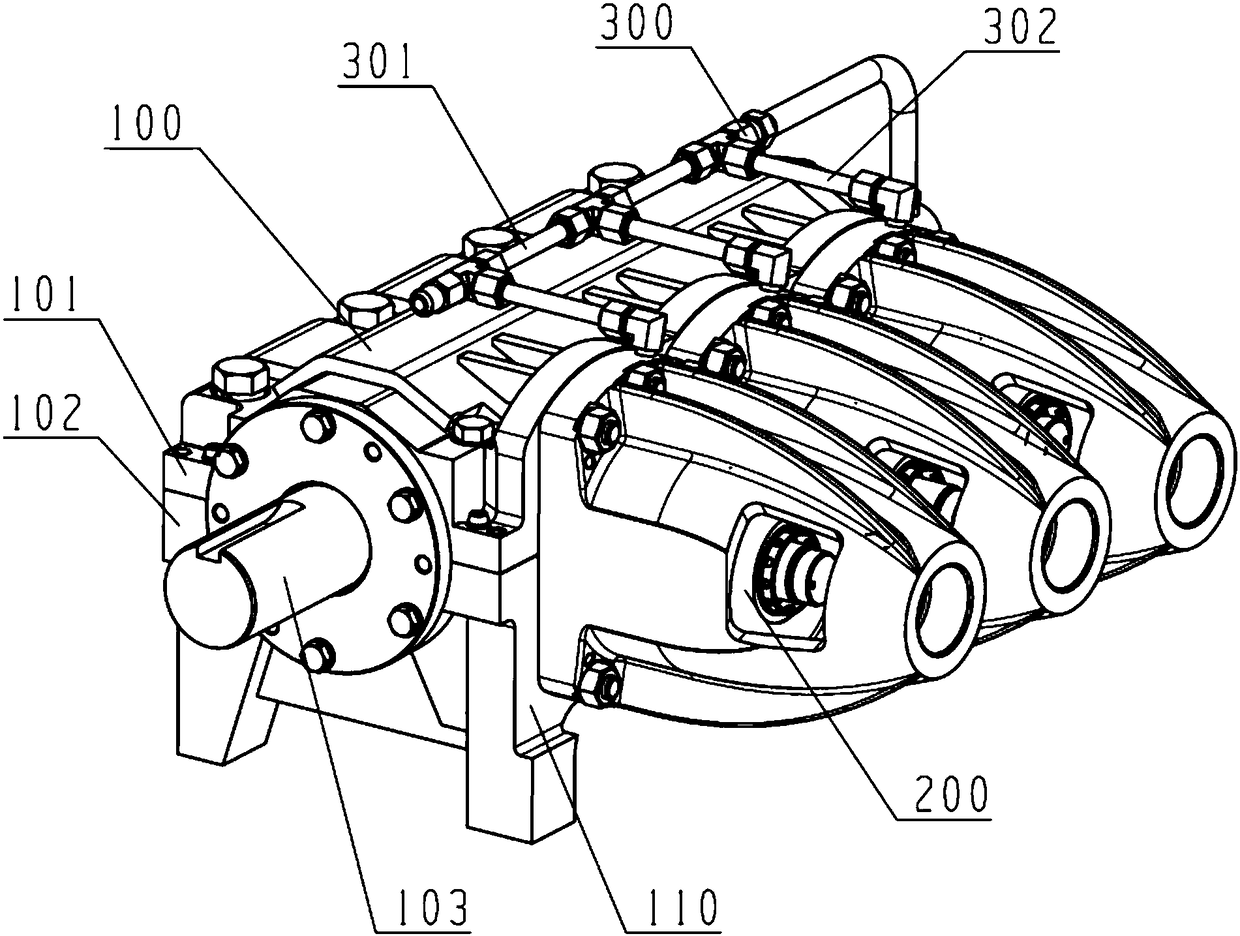

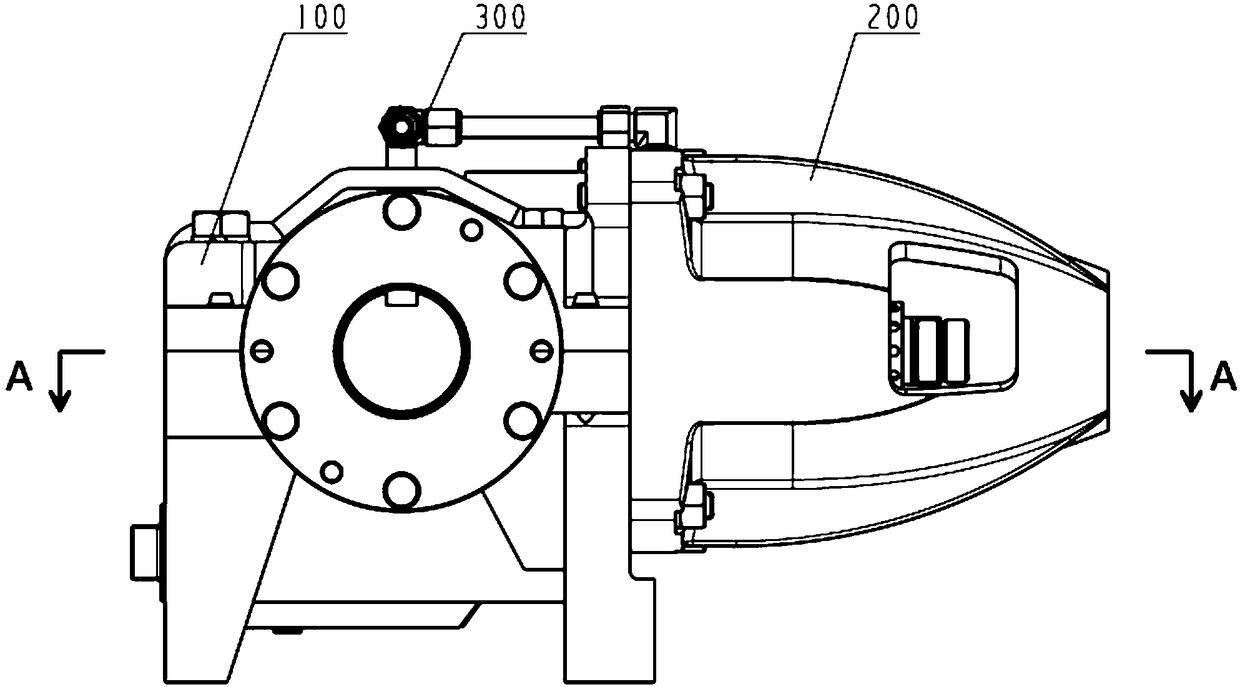

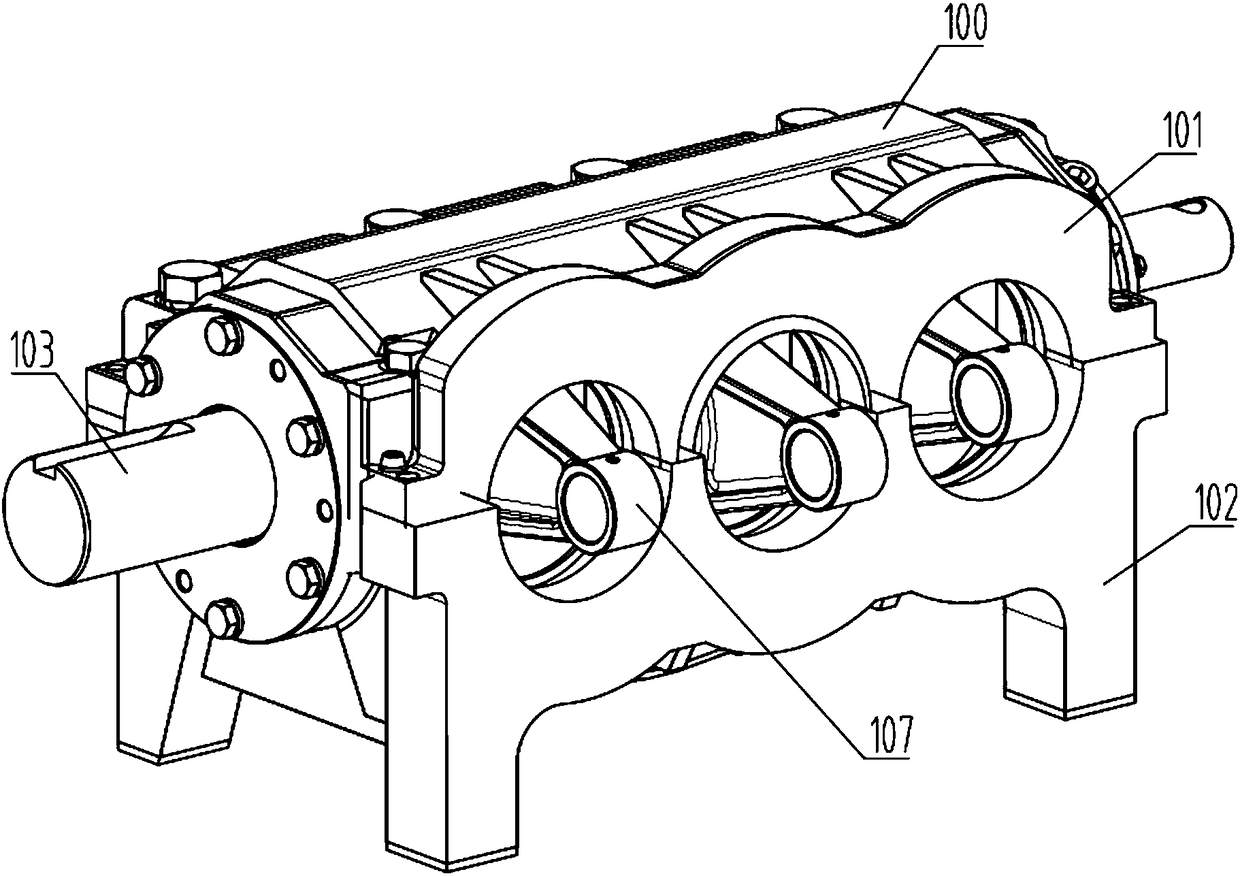

[0028] Examples such as Figures 1 to 6 As shown, a liquid nitrogen pump power end assembly includes a crankcase assembly 100, the crankcase assembly 100 is connected with a cross housing assembly 200 correspondingly, the crankcase assembly 100 and the cross housing assembly 200 A lubrication system 300 is correspondingly provided between them, and the crankcase body assembly 100 includes a crankcase welding shell 110. There are four crankcase bearing seats 109 inside the crankcase welding shell 110, and four crankcase bearing seats 109 are installed correspondingly. Crankshaft bearing 106, crankshaft bearing 106 is provided with crankshaft, crankshaft is connected with connecting rod 107, and crankcase welding shell 110 comprises crankcase casing 101 and crankcase cover 102, and crankcase casing 101 and crankcase cover 102 pass through Eight crankcase fixing bolts 108 are connected, the mating surface of the crankcase body 101 and the crosshead housing assembly 200 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com