Casting type mixture asphalt material and preparation method thereof

A technology of asphalt materials and mixtures, applied in building insulation materials, building components, buildings, etc., can solve problems such as pouring asphalt concrete, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Composed of the following components in parts by mass:

[0024] Base bitumen 85.5 parts

[0025] Modifier 9 parts

[0026] 4 parts filling oil

[0027] Accelerator 0.15 parts

[0028] (2) Add the modifier to the base asphalt at 140°C, high-shear at 170-180°C for 60 minutes at a speed of 2500 rpm, take samples to observe sufficient swelling, add filler oil and shear at the same speed for 15 minutes.

[0029] (3) Add the accelerator to the sample at 170-180 ° C and then high-shear for 90 minutes, and the rotation speed is 3500 rpm.

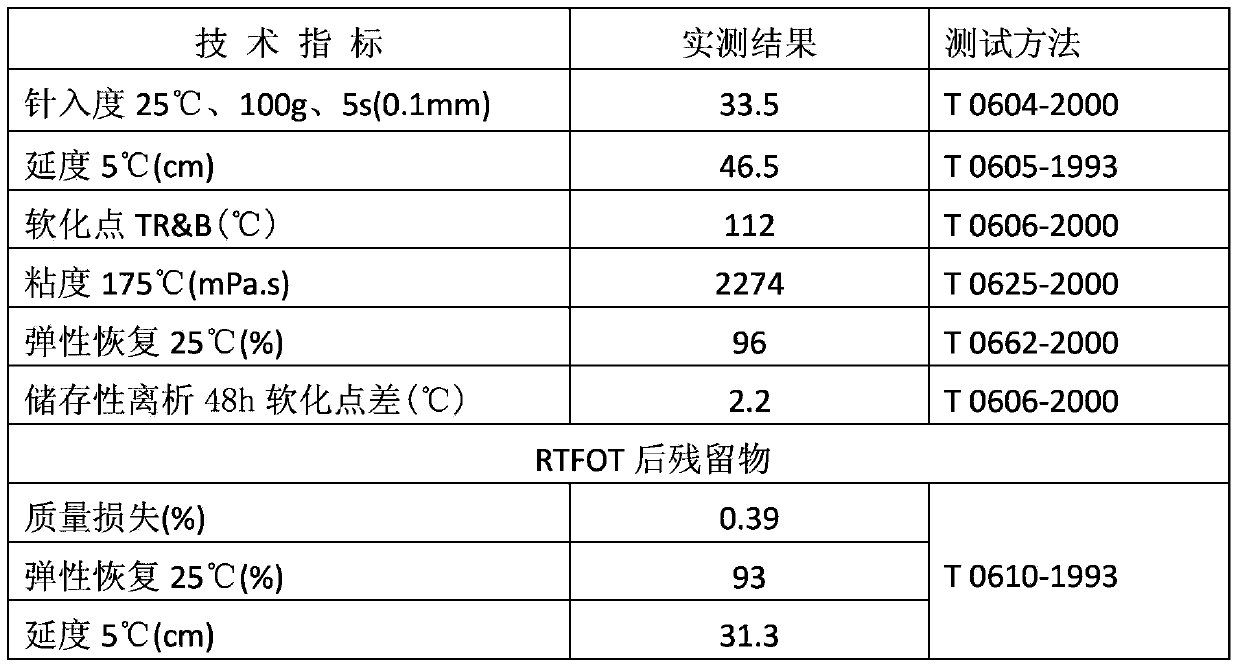

[0030] Table 1 Example 1 Performance of high-performance high-viscosity modified asphalt

[0031]

Embodiment 2

[0033] Consists of the following components in parts by mass:

[0034] Base bitumen 78.75 parts

[0035] Modifier 14 parts

[0036] Filling oil 7 parts

[0037] Accelerator 0.25 parts

[0038] (2) Add the modifier to the base asphalt at 140°C, high-shear at 170-180°C for 60 minutes at a speed of 3500 rpm, take samples to observe sufficient swelling, add filler oil and shear at the same speed for 25 minutes.

[0039] (3) Add the accelerator to the sample at 170-180 °C and then high-shear for 90 minutes, and the rotation speed is 4500 rpm.

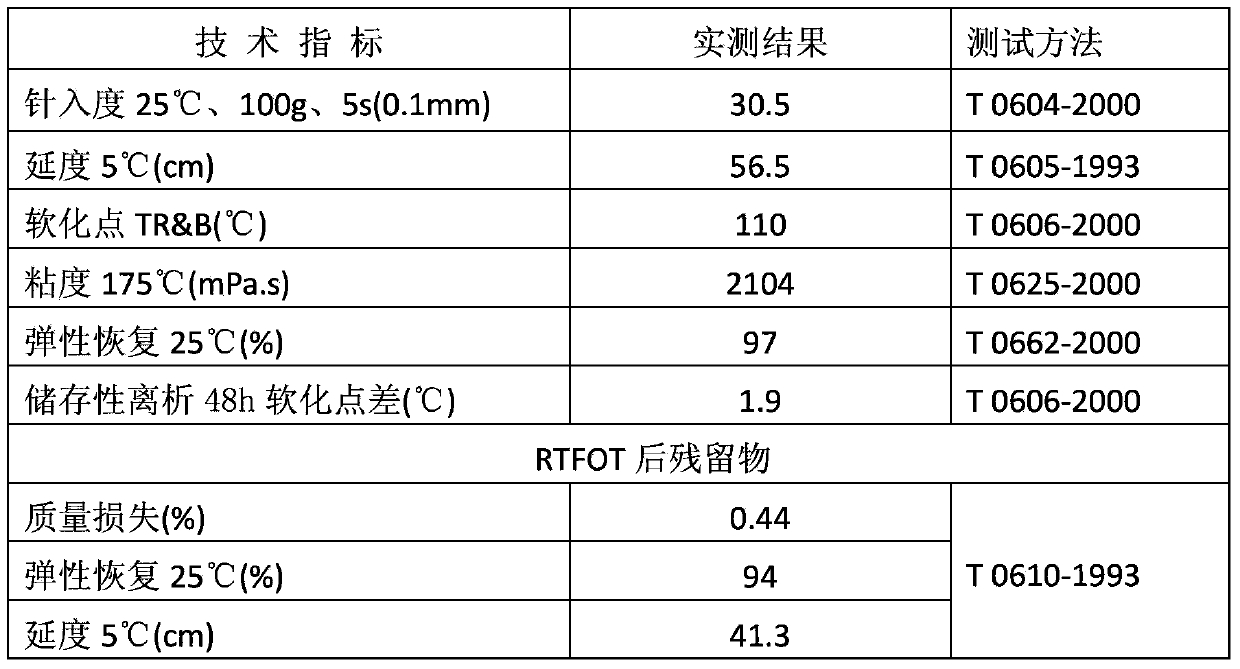

[0040] The performance of the high-performance high-viscosity modified asphalt of table 2 embodiment two

[0041]

[0042] From the results of Example 1 and Example 2, it can be seen that the developed high-performance high-viscosity modified asphalt not only has a higher softening point and hardness, but also has excellent elastic recovery and thermal aging properties. At the same time, the thermal storage stability is also very goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com