Method for recovering gold and lead by smelting refractory gold ore and lead-containing waste residue raw materials through oxygen enrichment molten pool

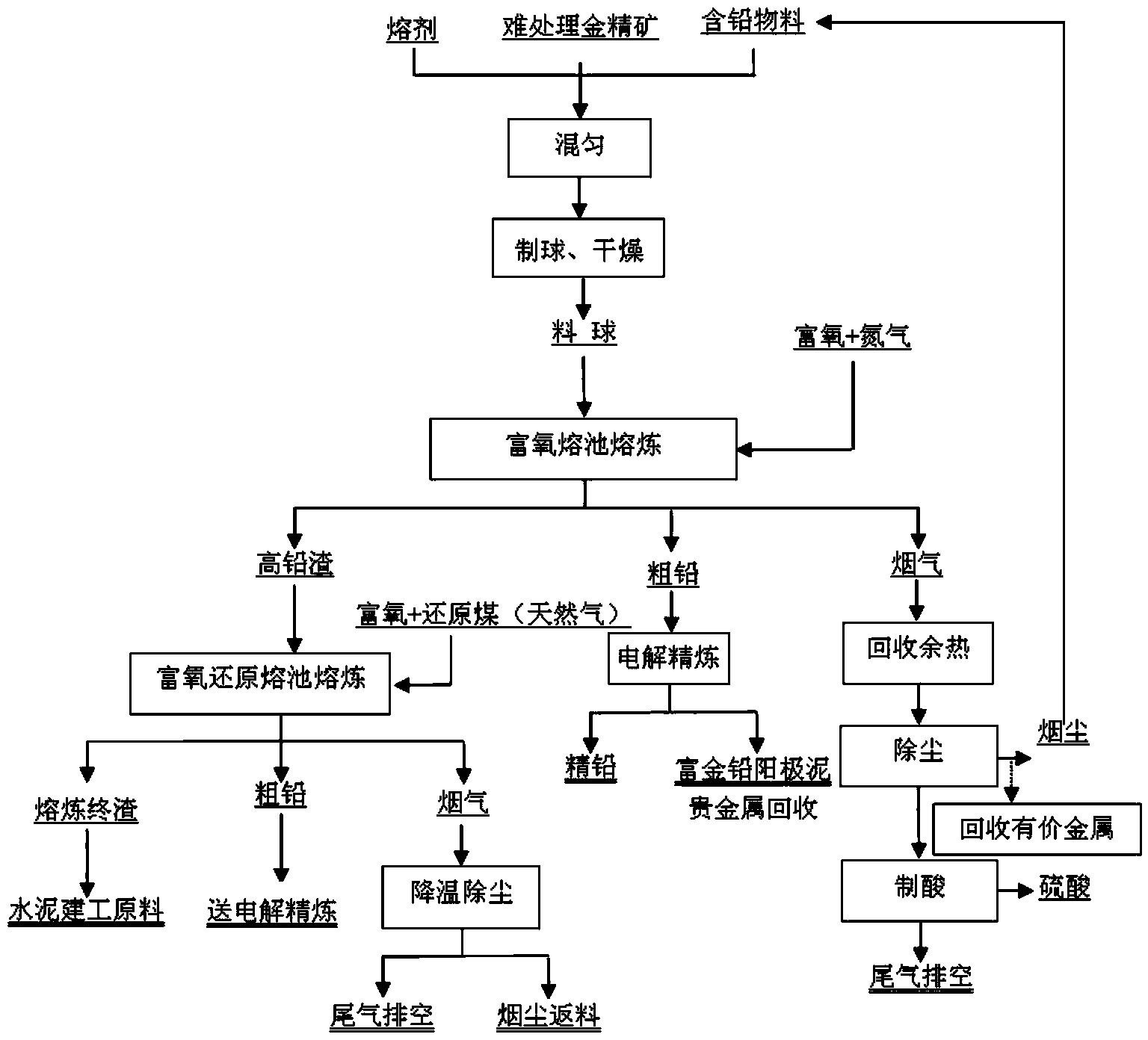

A technology for smelting and refractory gold ore in an oxygen-enriched molten pool, applied in the field of gold smelting, can solve the problems of sluggish resources, pollution, high energy consumption, etc., and achieve the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix high-sulfur gold ore (with a particle size range of 0.08-0.5mm), hydrometallurgy slag (with a particle size range of 0.05-5mm) and limestone (with a particle size range of 2-15mm) evenly, then granulate and dry When the moisture content is about 8%, pellets with a particle size of about 20mm are obtained; the main components of the pellets are Pb20.01%, SiO 2 10.86%, FeO10.67%, CaO5.07%, S10.63%, Au10g / t; the obtained pellets are placed in an oxygen bottom-blown furnace, with 180Nm 3 The rate of each ton of pellets is fed with oxygen-enriched air with an oxygen volume percentage of 40%, and oxidized and smelted at a high temperature of 1100-1200°C for 100 minutes to obtain flue gas, crude lead and high-lead slag with a sulfur dioxide concentration greater than 20% by volume. Gained high-lead slag joins in the reduction furnace, sprays into coal dust (coal powder addition is 100kg per ton high-lead slag, granularity is 0.1~0.8mm) in reduction furnace, simultaneously...

Embodiment 2

[0037] After mixing high-carbon gold ore (with a particle size range of 0.1-1mm), lead-acid battery mud (with a particle size range of 1-8mm) and river sand (with a particle size range of 2-10mm) powders, granulate and dry to The moisture content is about 8%, and the pellets with a particle size of about 25mm are obtained; the main components of the pellets are Pb15.8%, SiO 2 20.96%, FeO20.09%, CaO10.44%, S20.3%, Au14g / t; the obtained pellets are placed in an oxygen bottom-blown furnace, with 120Nm 3 The rate per ton of pellets is passed into oxygen-enriched air with an oxygen volume percentage of 80%, and oxidized and smelted at a high temperature of 1150-1250°C for 60 minutes to obtain flue gas, crude lead and high-lead slag with a sulfur dioxide concentration greater than 20% by volume. ; Gained high lead slag joins in the reduction furnace, in the reduction furnace with 40Nm 3 The amount of high lead slag per ton is fed into natural gas, and at the same time, 60Nm 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com