Low-grade copper-bearing gold ore dump leaching-carbon adsorption production method

A low-grade, carbon adsorption technology, applied in the field of metallurgy, can solve the problems of poor operating environment, low ammonia recovery rate of ammonia leaching solution, high safety operation requirements, etc., to achieve low production costs, optimize production technical indicators, and improve gold. Effect of desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

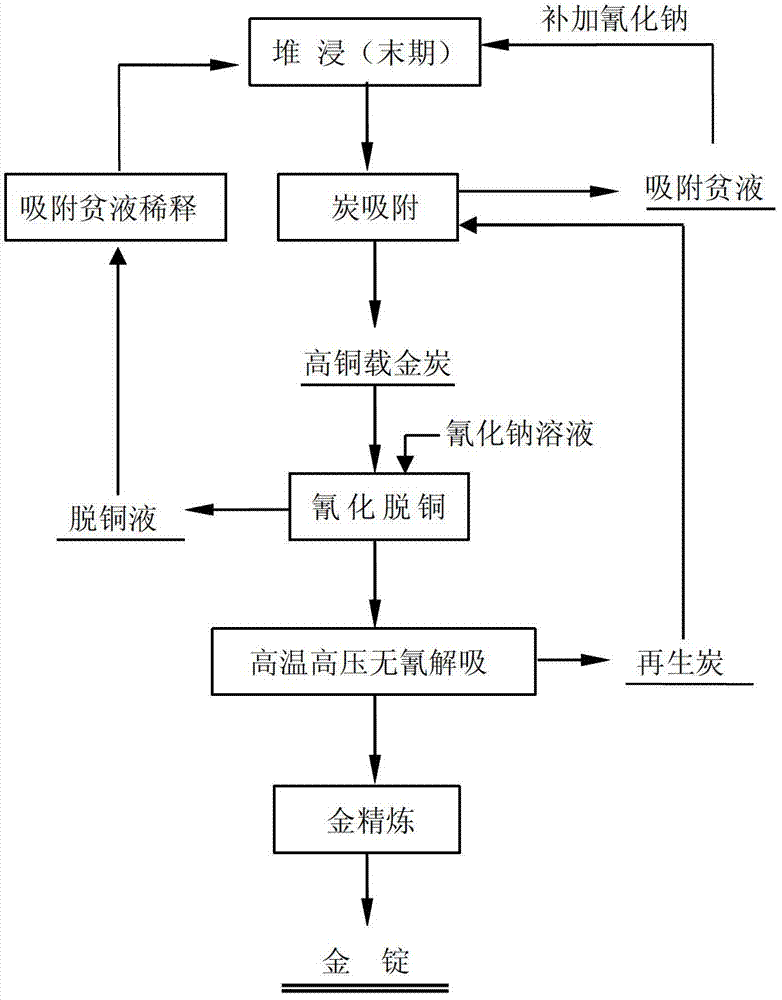

Image

Examples

Embodiment 1

[0021] The low-grade copper-bearing gold ore with a gold grade of 0.5g / t and a copper content of 0.03% is subjected to heap leaching and cyanidation leaching, and the leached liquid is adsorbed by activated carbon; Cyanide copper removal under the condition of 3% sodium for 18 hours, and the carbon layer was agitated by air every 15 to 30 minutes; the copper removal solution was diluted with adsorption barren solution to a concentration of sodium cyanide <50mg / L and then used as the spray solution at the end of heap leaching. Part of the copper is re-precipitated in the storage yard, and the sodium cyanide produced by the copper precipitation reaction is used to leach gold; the decoppered carbon is sent to a high-temperature and high-pressure cyanide-free desorption-electrowinning system for treatment, and the obtained coarse gold powder is refined to obtain gold Ingots, the regenerated carbon is returned to the carbon adsorption system. The average concentration of copper in ...

Embodiment 2

[0023] The low-grade copper-bearing gold ore with a gold grade of 0.5g / t and a copper content of 0.03% is subjected to heap leaching and cyanidation leaching, and the leaching liquid is adsorbed by activated carbon; Under the condition of 5% sodium, cyanide decopper for 36 hours, agitate the carbon layer with air every 15-30 minutes; the decopper solution is diluted with adsorption barren solution until the concentration of sodium cyanide is less than 50mg / L, and then it is used as the spray solution at the end of heap leaching. Part of the copper is re-precipitated in the storage yard, and the sodium cyanide produced by the copper precipitation reaction is used to leach gold; the decoppered carbon is sent to a high-temperature and high-pressure cyanide-free desorption-electrowinning system for treatment, and the obtained coarse gold powder is refined to obtain gold Ingots, the regenerated carbon is returned to the carbon adsorption system. The average copper concentration in ...

Embodiment 3

[0025] The low-grade copper-bearing gold ore with a gold grade of 0.5g / t and a copper content of 0.03% is subjected to heap leaching and cyanidation leaching, and the leaching liquid is adsorbed by activated carbon; Under the condition of 2% sodium, cyanide decopper for 15 hours, and the carbon layer is stirred by air every 15-30 minutes; the decopper solution is diluted with adsorption barren solution until the concentration of sodium cyanide is less than 50mg / L, and then it is used as the spray solution at the end of heap leaching. Part of the copper is re-precipitated in the storage yard, and the sodium cyanide produced by the copper precipitation reaction is used to leach gold; the decoppered carbon is sent to a high-temperature and high-pressure cyanide-free desorption-electrowinning system for treatment, and the obtained coarse gold powder is refined to obtain gold Ingots, the regenerated carbon is returned to the carbon adsorption system. The copper concentration in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com