Floating process for enriching Cu, Ag, Au, etc from gold sulfide ore cyanizing gold extraction tailing

A gold sulfide and enrichment technology, which is applied in the field of flotation technology, can solve the problems of incomplete recycling and waste of resources, and achieve good promotion and application value, improve comprehensive utilization, and high metal recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

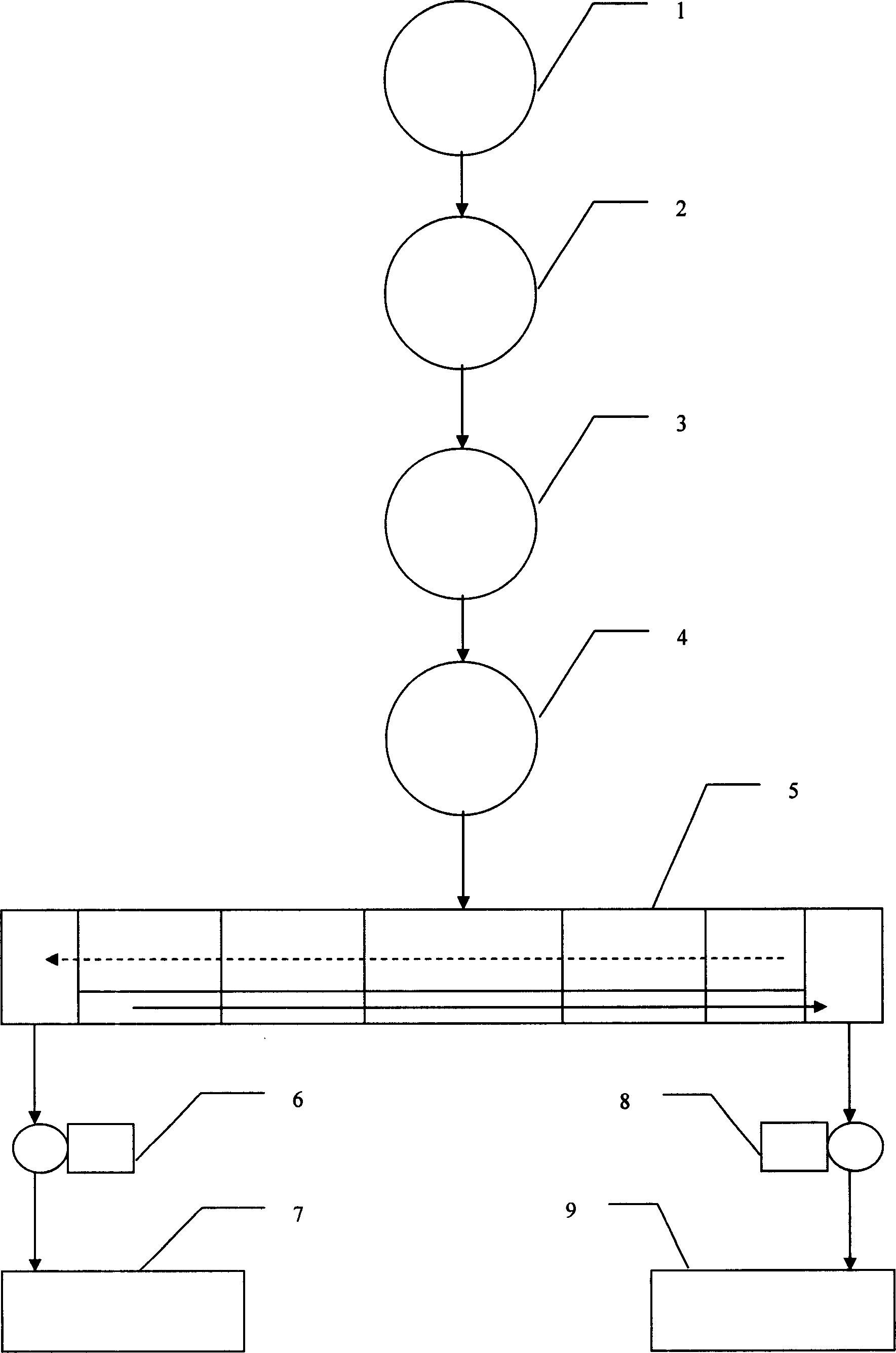

[0022] Add the cyanide-treated sulfide gold concentrate gold extraction tailings into the slurry mixing tank 1, add water to adjust the slurry concentration to 50%, stir continuously at normal temperature and pressure, and after stirring evenly, put the rings into three parallel acidification tanks In step 2, add industrial sulfuric acid, adjust the acidity of the pulp to PH=5, stir continuously for 20 minutes, and keep the acidity at PH=5, and after the acidity is stable, put the pulp into the slurry mixing tank 3 continuously, stably and evenly, and add water to adjust the concentration of the pulp 25%, PH = 6, and continuous feeding and discharging, the pulp enters the stirring tank 4, while stirring, continuously and evenly add flotation reagents, the flotation reagents are butyl xanthate and butylamine black medicine, Mix and prepare according to the ratio of butyl xanthate: butylamine black medicine = 1.8:1, add flotation agent at 100 g / ton, add 2# oil foaming agent at 42...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is that

[0038] Add the cyanide-treated sulfide gold concentrate gold extraction tailings into the slurry mixing tank 1, add water to adjust the slurry concentration to 40%, stir continuously at normal temperature and pressure, and after stirring evenly, put the rings into three acidizing tanks connected in parallel In step 2, add industrial sulfuric acid, adjust the acidity of the pulp to PH=5, and continue to stir for 15 minutes to keep the acidity at PH=5. After the acidity is stable, put the pulp into the slurry tank 3 continuously and evenly, and add water to adjust the concentration of the pulp 20%, PH = 6, and continuous feeding and discharging, the pulp enters the stirring tank 4, and while stirring, continuously and evenly adds the flotation agent, the flotation agent is butyl xanthate and butylamine black drug, Mix and prepare according to the ratio of butyl xanthate: butylamine black medicine = 2.2:1, a...

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is that

[0041] Add the cyanide-treated sulfide gold concentrate gold extraction tailings into the slurry mixing tank 1, add water to adjust the slurry concentration to 60%, keep stirring at normal temperature and pressure, and after stirring evenly, put the rings into three parallel acidification tanks In step 2, add industrial sulfuric acid, adjust the acidity of the pulp to PH=5, continue to stir for 25 minutes, and keep the acidity at PH=5. After the acidity is stable, put the pulp into the slurry mixing tank 3 continuously and evenly, and add water to adjust the concentration of the pulp 30%, PH = 6, and continuous feeding and discharging, the pulp enters the stirring tank 4, while stirring, continuously and evenly add flotation reagents, the flotation reagents are butyl xanthate and butylamine black medicine, Mix and prepare according to the ratio of butyl xanthate: butylamine black medicine = 2:1, add flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com