Method for floatation and recovery of lead zinc mixed concentrate from gold mine cyaniding slag tails

A technology for cyaniding tailings and mixed concentrates, applied in flotation, process efficiency improvement, solid separation, etc., can solve problems such as excess flotation reagents, high cyanide concentration, and impact, and achieve good flotation effect, The effect of high recovery rate of lead and zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

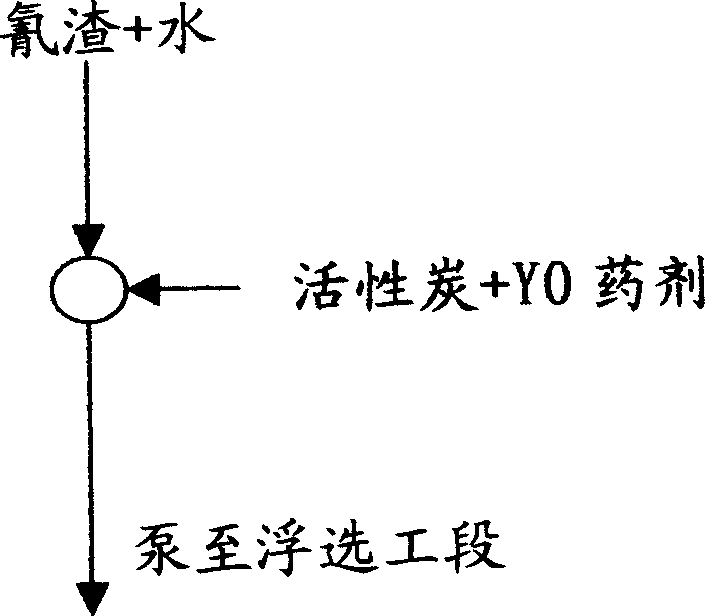

[0030] (1) Pretreatment of gold ore cyanidation tailings:

[0031] Add water to the cyanide tailings, stir to form a slurry, add activated carbon and YO chemicals to the slurry,

[0032] The pretreatment process conditions are:

[0033] Pulp concentration: 35%

[0034] Activated carbon dosage: 1.3Kg / T

[0035] Dosage of YO agent: 0.2Kg / T, YO agent component is 1 part of FeSO 4 +3 parts ammonium persulfate

[0036] Stirring time: 30 minutes

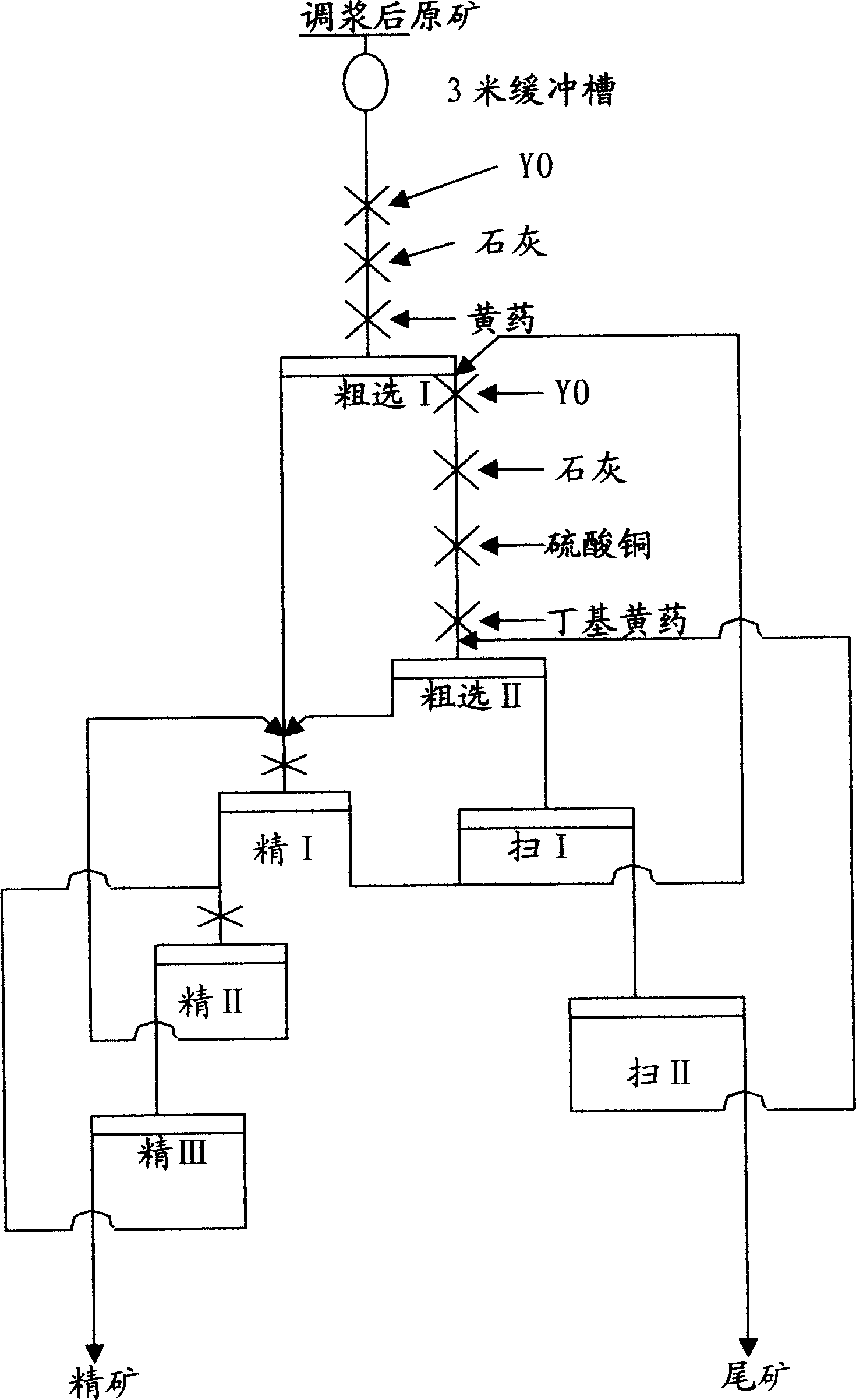

[0037] (2) Asynchronous mixed selection:

[0038] Pump the pretreated ore slurry to the flotation unit I for the first step of roughing, add YO agent, lime, butyl xanthate, and float the galena; send the tailings slurry after the first step of roughing to Go to the flotation unit II, then enter the second step of roughing, add YO reagent, lime, copper sulfate, butyl xanthate, and flotation sphalerite.

[0039] The process conditions of asynchronous mixed selection are:

[0040] The first rough selection: PH value: 9

[0041] YO: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com