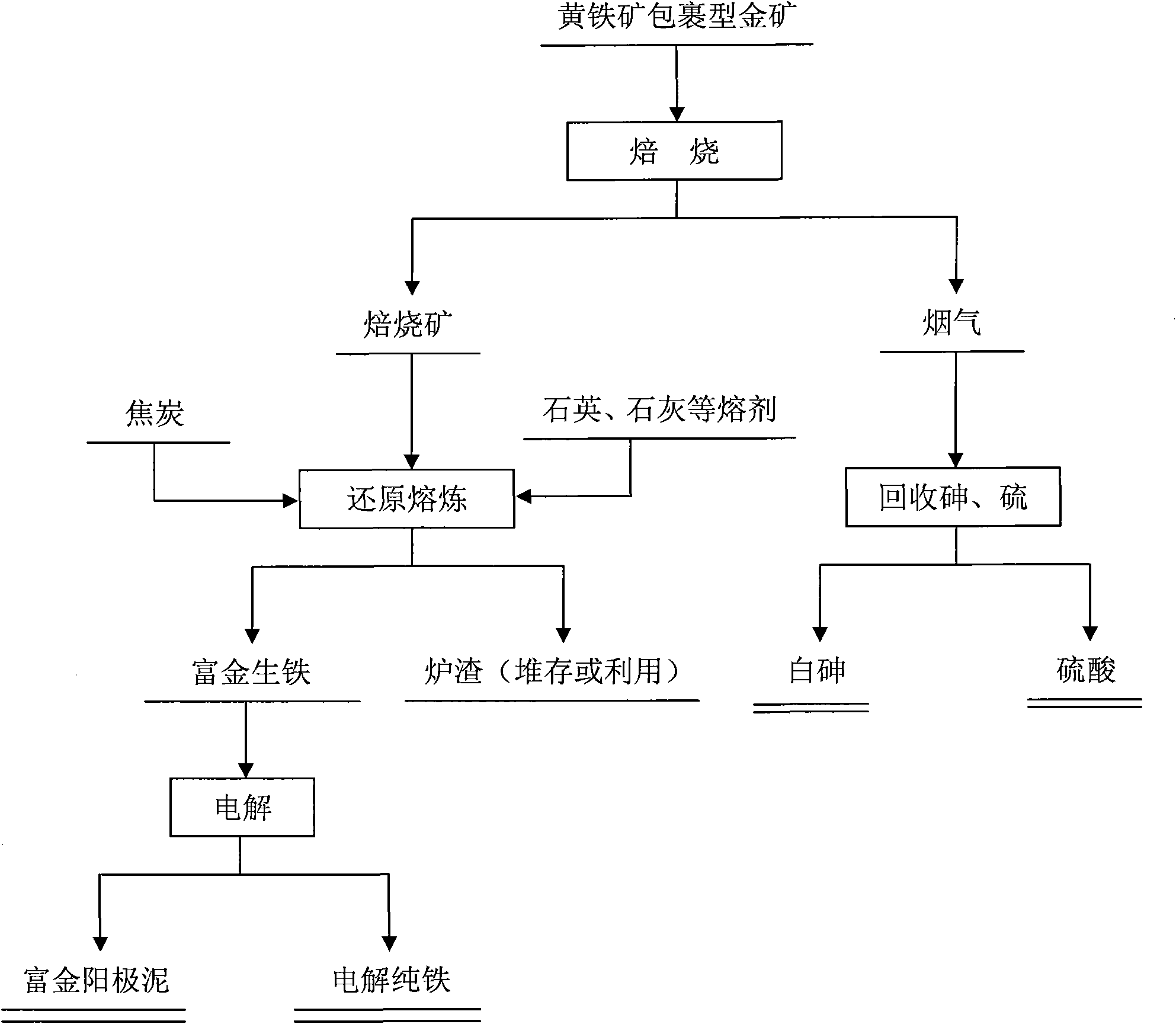

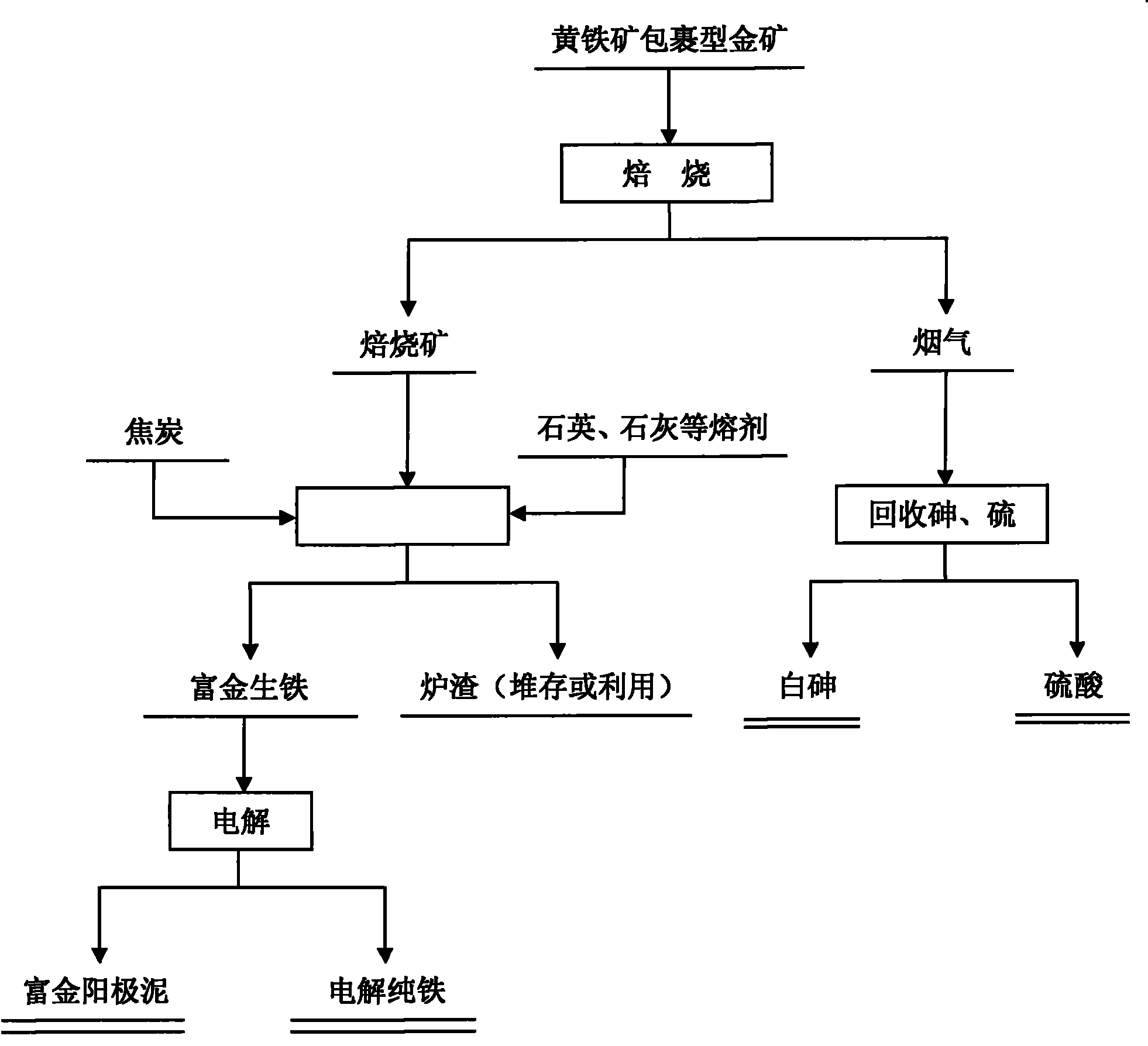

Method for concentrating gold from pyrite inclusion-type gold ore

A wrapped type, pyrite technology, applied in the field of raw material pretreatment and roasting process, can solve the problems of low gold recovery rate, poor stability, large amount of slag, etc., to achieve high gold recovery rate, high stability, and resources The effect of high comprehensive recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1: Roasted ore composition is Fe 60.22%, Pb 0.78%, Zn 0.77%, S 0.25%, As 0.063%, Cu 0.061%, P 0.029%, SiO 2 9.38%, Al 2 o 3 1.33%, MgO 0.094%, CaO 1.14, Au 8.28g / t. Using DC electric arc furnace for smelting, under the condition that the mass ratio of roasted ore: coke: lime is 10:3:1, and smelting at 1500 ° C, the iron reduction rate reaches 98%, and 99% of gold is enriched in pig iron. Gold-rich pig iron The composition is: Fe 97.27%, C 1.38%, Si 0.29%, S 0.40%, P 0.052%, Au 13.74g / t. The gold-rich pig iron is cast into the anode, and in the electrolyte system based on ferrous sulfate-ammonium sulfate, the Fe 2+ 80g / L, (NH 4 ) 2 SO 4 80g / L, pH=3.5~4.5, electrolyte temperature 50~60℃, 220~275A / m 2 The current density and the cell voltage of 1.0-1.2V, the center distance of the same pole is set at 110mm, when the diaphragm electrolysis is used, the electrolysis proceeds stably, and the output of pure iron with iron content greater than 99.5% and impuri...

example 2

[0021] Example 2: Roasted ore composition is Fe 60.22%, Pb 0.78%, Zn 0.77%, S 0.25%, As 0.063%, Cu 0.061%, P 0.029%, SiO 2 9.38%, Al 2 o 3 1.33%, MgO 0.094%, CaO 1.14, Au 8.28g / t. Using DC electric arc furnace for smelting, under the condition that the mass ratio of roasted ore: coke: lime is 10:2:3, and smelting at 1550 ° C, the iron reduction rate reaches 95%, and 98% of gold is enriched in pig iron. Gold-rich pig iron The composition is: Fe 94.88%, C 0.44%, Si 2.52%, S 0.56%, P 0.056%, Au 13.73g / t. The gold-rich pig iron is cast into the anode, and in the electrolyte system based on ferrous sulfate-ammonium sulfate, the Fe 2+ 100g / L, (NH 4 ) 2 SO 4 100g / L, pH=3.5~4.5, electrolyte temperature 50~60℃, 220~275A / m 2 The current density and the cell voltage of 1.0-1.2V, the center distance of the same pole is set at 120mm, when the diaphragm electrolysis is used, the electrolysis is carried out stably, and the pure iron with iron content > 99.5% and impurities within th...

example 3

[0022] Example 3: Roasted ore composition is Fe 61.22%, Pb 0.61%, Zn 0.32%, S 0.23%, As 0.17%, Cu 0.035%, P 0.04%, SiO 2 8.15%, Al 2 o 3 1.36%, MgO 0.075%, CaO 0.73%, Au 30.30g / t. Using DC electric arc furnace for smelting, under the condition of roasted ore: coke: lime mass ratio of 10:4:1, smelting at 1500 ° C, the iron reduction rate reaches 99%, and 99% of gold is enriched in pig iron, gold-rich pig iron The composition is: Fe 97.32%, C 1.44%, Si 0.52%, S 0.52%, P 0.053%, Au 49.16g / t. The gold-rich pig iron is cast into the anode, and in the electrolyte system based on ferrous sulfate-ammonium sulfate, the Fe 2+ 100g / L, (NH 4 ) 2 SO 4 100g / L, pH=3.5~4.5, electrolyte temperature 50~60℃, 220~275A / m 2 The current density and the cell voltage of 1.0-1.2V, the center distance of the same pole is set at 11mm, when the diaphragm electrolysis is used, the electrolysis is carried out stably, and the pure iron with iron content greater than 99.5% and impurities within the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com