Beneficiation process for increasing recovery rate of gold of refractory gold ores

A technology for refractory gold ore and recovery rate, applied in the field of mineral processing technology, can solve the problems of low concentrate grade, low gold recovery rate, loss, etc., to improve the dissociation degree, improve the grade and metal recovery rate, and achieve good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

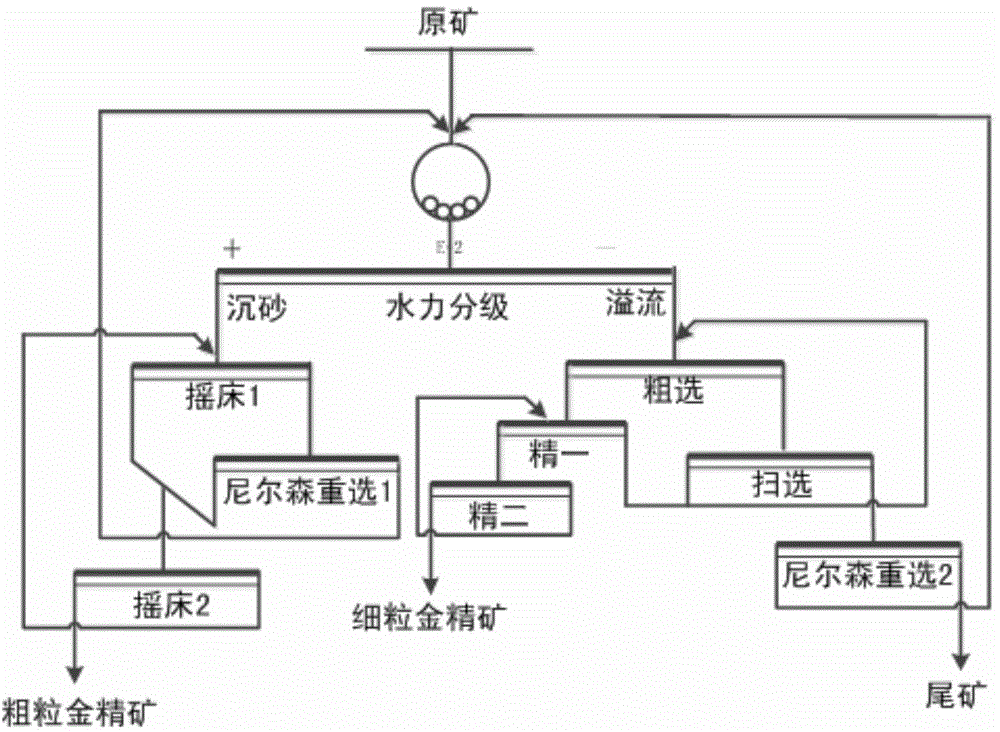

Method used

Image

Examples

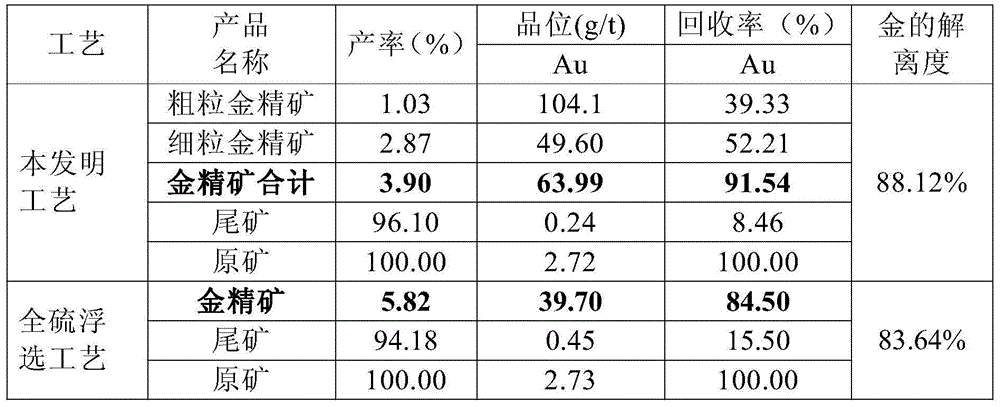

Embodiment 1

[0030] 1. Raw ore

[0031] Altered rock-type gold ore in a broken zone in Menghai County, Xishuangbanna, Yunnan. The ore contains 2.72g / t gold and 1.53% sulfur. The main metal minerals are pyrite and pyrrhotite, followed by arsenopyrite, galena and stibnite; the main gangue minerals are quartz, chlorite, mica and calcite. The ore structure is dominated by granular structure, fragmentation structure, and metasomatous structure, followed by granular metamorphic structure, heteromorphic granular structure, and metasomatized residual structure; the ore structure is dominated by breccia structure and disseminated structure, followed by network veins Shaped structure, massive structure, vein-like interspersed structure, etc. The distribution rate of gold in the ore is as follows: gold in natural gold accounts for 28.76%, which belongs to the form of natural elements; gold in pyrite and pyrrhotite accounts for 58.04%; gold in arsenopyrite accounts for 5.45%; Gold in copper ore acco...

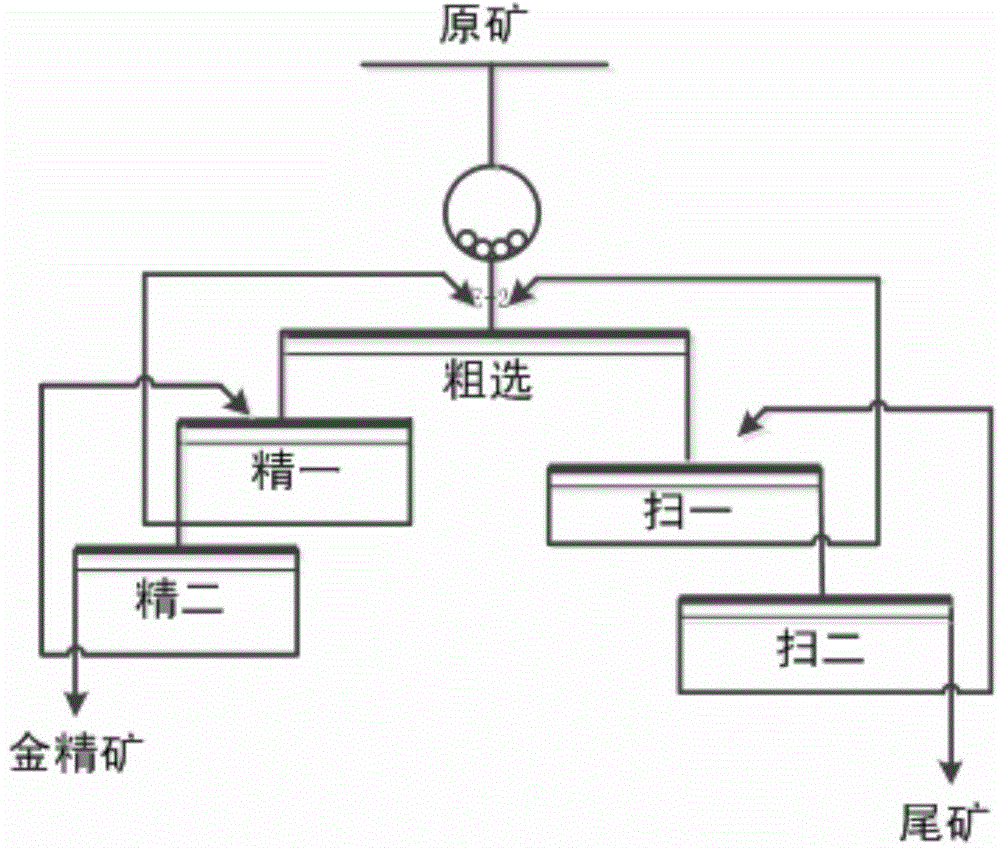

Embodiment 2

[0048] 1. Raw ore

[0049] Altered rock-type gold ore in a broken zone in Cangwu County, Guangxi Province. The ore contains 3.35g / t gold and 2.17% sulfur. The main metal minerals are natural gold, pyrite, pyrrhotite, arsenopyrite, followed by chalcopyrite, galena, sphalerite, brittle stibnite, with a content of 5%-10%; gangue minerals are Quartz, calcite, chlorite and tuffaceous sandstone. The ore structure has euhedral, semi-euhedral, other granular, fragmented, crushed and skeletal crystal structures. The ore structure is mainly veinlet disseminated structure, massive structure, breccia structure, and occasionally geode structure. There are two kinds of gold occurrence states, one is in the form of natural gold, the particle size is generally 0.06-1.0mm, and some are larger than 2mm, and most of them are irregular, short columnar, granular, plum-shaped, flake, etc. In cracked quartz or crushed breccia altered rock, the other is filled in pyrite and other sulfide and quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com