Method for wet-leaching lateritic-nickel ore at transition layer

A technology of laterite nickel ore and transition layer, applied in the field of hydrometallurgy, can solve the problems of low metal recovery rate, achieve the effect of increasing nickel leaching rate and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

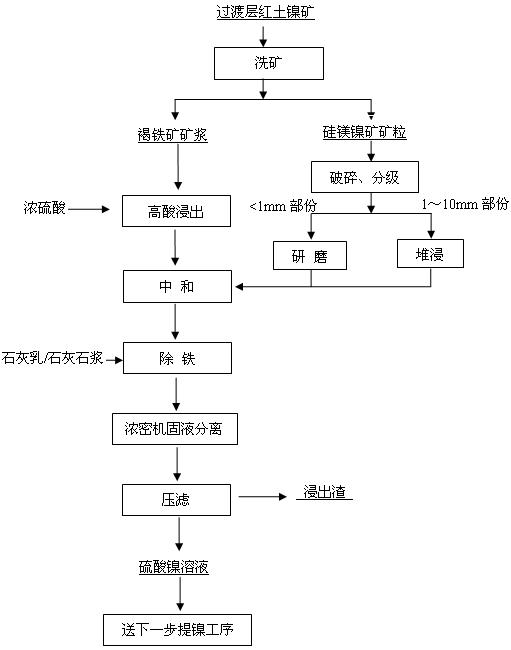

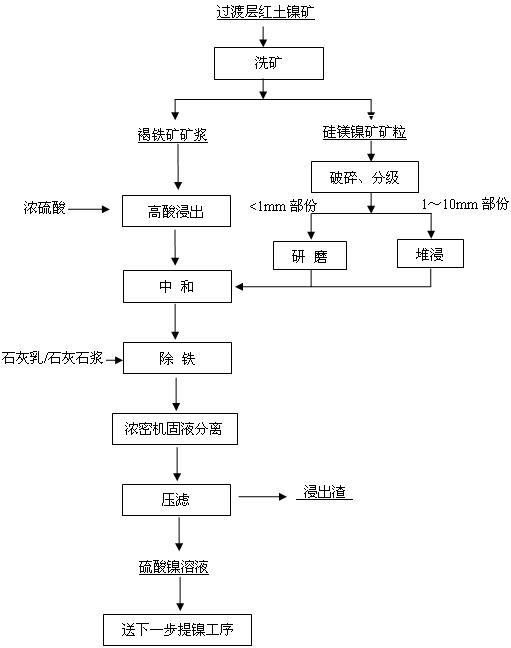

Image

Examples

Embodiment 1

[0027] A transition layer laterite nickel ore produced in Indonesia, the composition of which is shown in the following table after analysis of ore samples:

[0028]

[0029] Wash the laterite nickel ore, and the -100 mesh slurry directly obtained from the ore washing is the limonite-type laterite nickel ore slurry with high iron content and low magnesium content; the crushing and grading treatment of silicon magnesium nickel ore larger than 100 mesh, of which The part with a particle size of 1-10mm is directly sent to the heap leaching treatment; the part larger than 10mm is returned to the system for re-crushing and grading; the part smaller than 1mm is sent to a ball mill to be ground into -100 mesh pulp, and this part of the pulp is used It is used for neutralizing the Simagnesian ore slurry. Treat the washed limonite-type lateritic-nickel ore slurry with a thickener and concentrate it into a slurry with a solid content of 30%. This slurry is added to the stirring leach...

Embodiment 2

[0031] A kind of transition layer laterite nickel ore produced in Indonesia. The laterite nickel ore is washed first, and the -100 mesh pulp obtained directly from the washing is the limonite type laterite nickel ore pulp with high iron content and low magnesium content; The 100-mesh silicon-magnesium-nickel ore is crushed and classified, and the part with a particle size of 1 to 10 mm is directly sent to the heap leaching treatment; the part larger than 10 mm is returned to the system for re-crushing and grading; the part smaller than 1 mm is sent to a ball mill to be finely ground into -100 mesh silicon-magnesium-nickel ore slurry, the treated slurry is sampled and dried, and analyzed by the ore sample, its composition is shown in the following table:

[0032]

[0033] Treat the washed limonite-type lateritic-nickel ore slurry with a thickener and concentrate it into a slurry with a solid content of 30%. This slurry is added to the stirring leaching tank, and concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com