Acid washed ore leaching process for low-grade copper oxide ores with high mud content

A copper oxide ore, low-grade technology, applied in the field of copper hydrometallurgy, can solve the problems of low copper leaching rate, poor permeability of heap leaching, etc., and achieve the effect of less environmental pollution, low cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

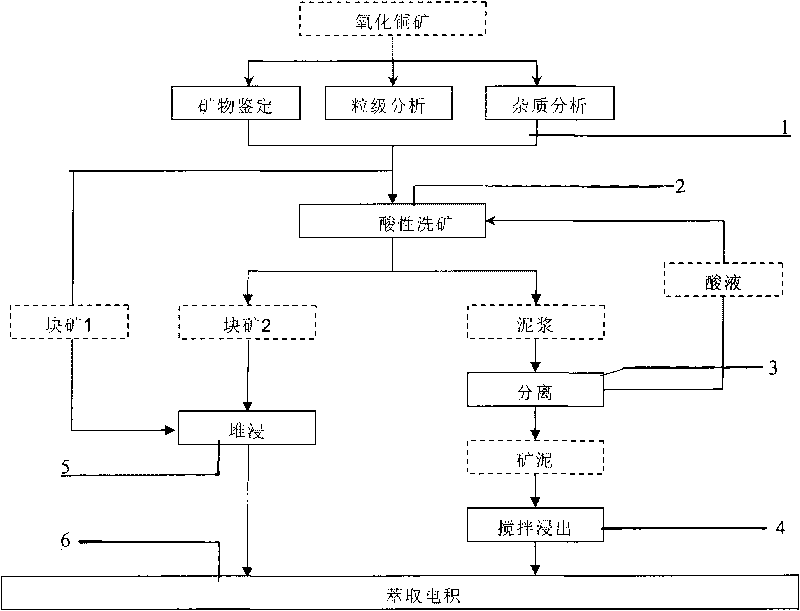

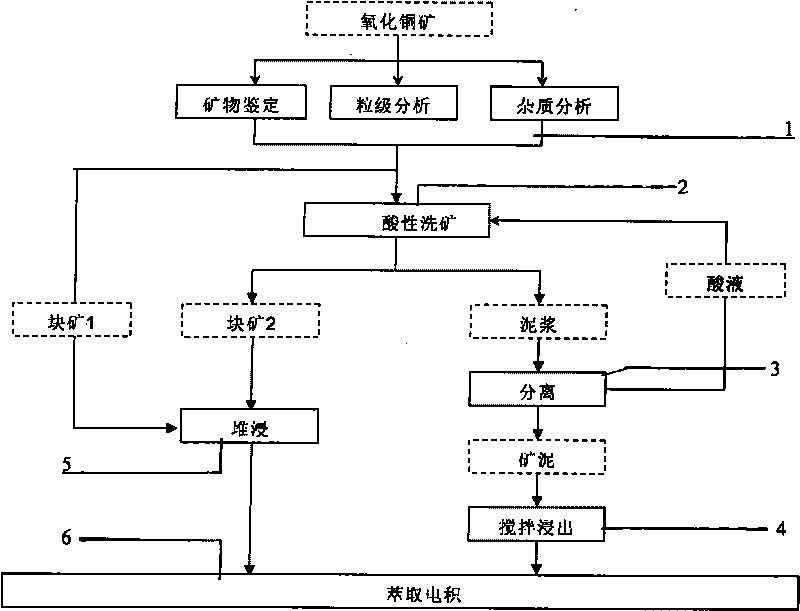

[0028] Such as figure 1 As shown, the raw ore is crushed and screened, the ore with a grain size of +50mm is sent to the stockyard for stacking, the ore with a grain size of -50mm is processed by the ore washing system, and the placer with a grain size of +0.074mm is sent to the stockyard for stacking, - The mud ore with a particle size of 0.074mm enters the stirring and leaching process. The leachate from agitation leaching and heap leaching are combined and then enter the extraction electrowinning process to finally obtain cathode copper products.

[0029] The present invention will be further described below in conjunction with embodiment:

[0030] This process is applied to a low-grade copper oxide ore with high mud content in the western region of my country. The copper oxide minerals are mainly malachite, blue copper ore, a small amount of bileite and black copper ore; the gangue minerals are mainly clay Minerals, feldspar alterations and a small amount of sericite and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com