Patents

Literature

30 results about "Tank leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metallurgical processes tank leaching is a hydrometallurgical method of extracting valuable material (usually metals) from ore.

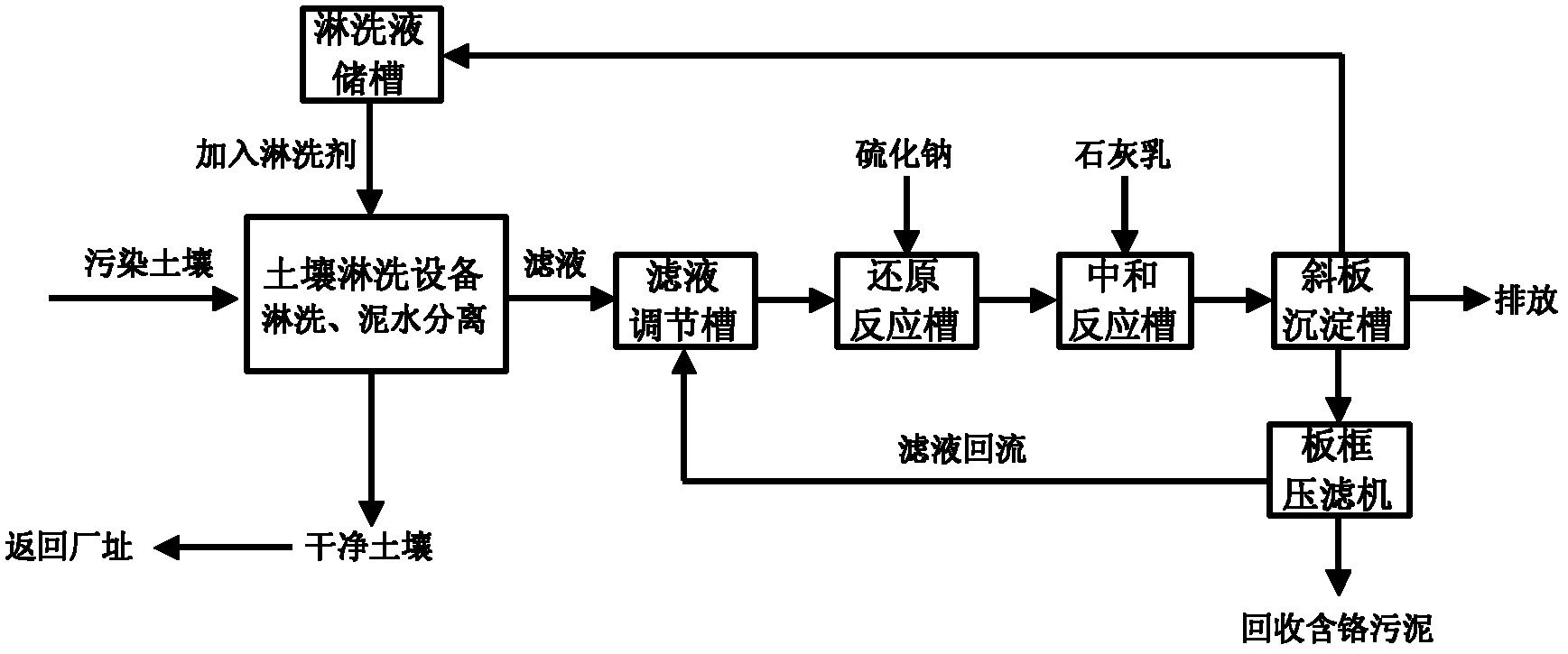

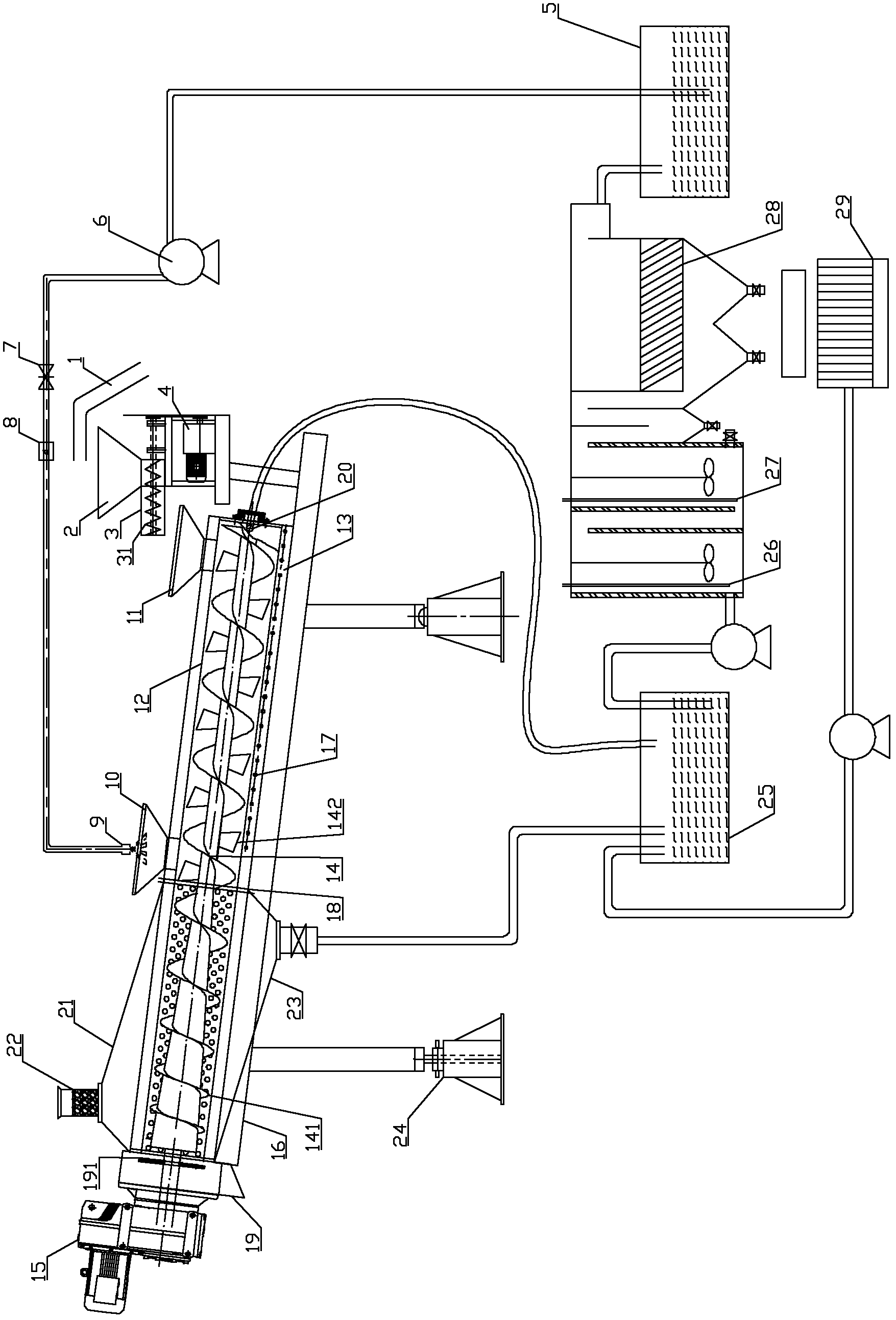

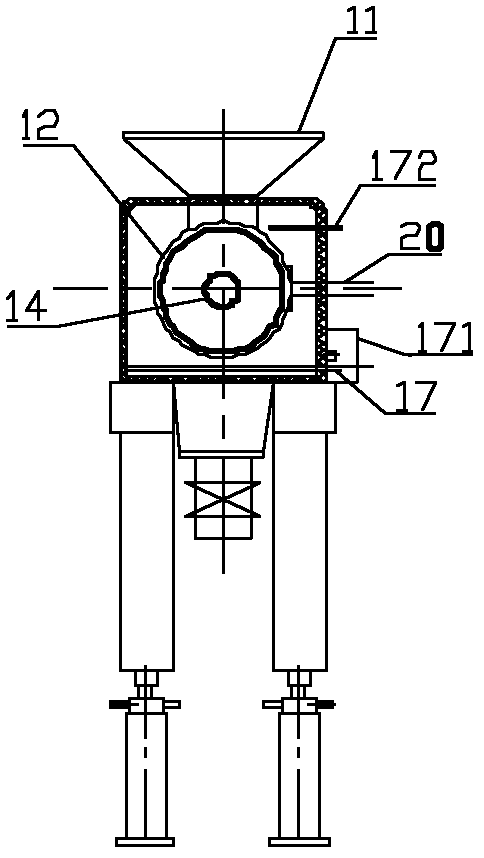

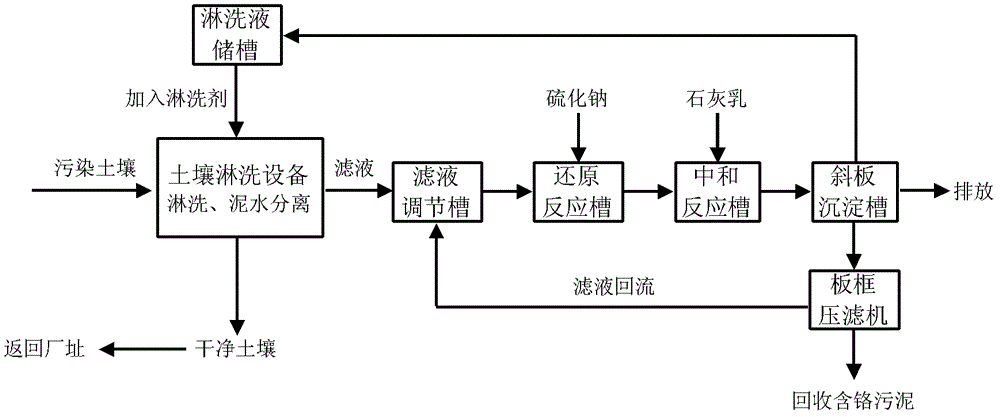

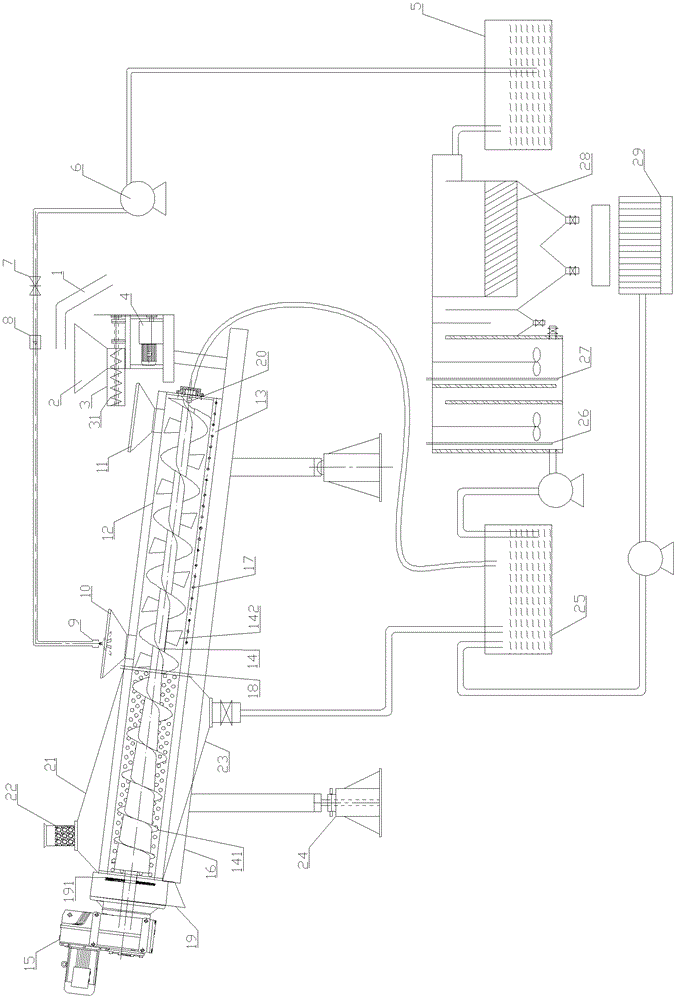

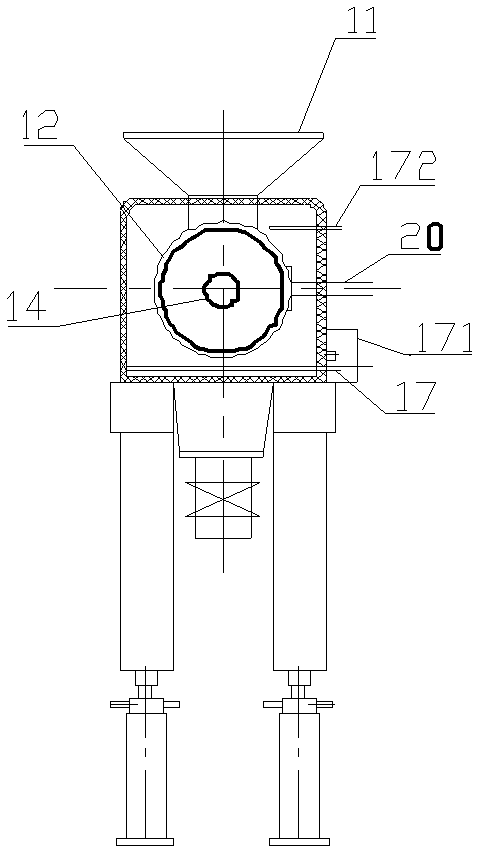

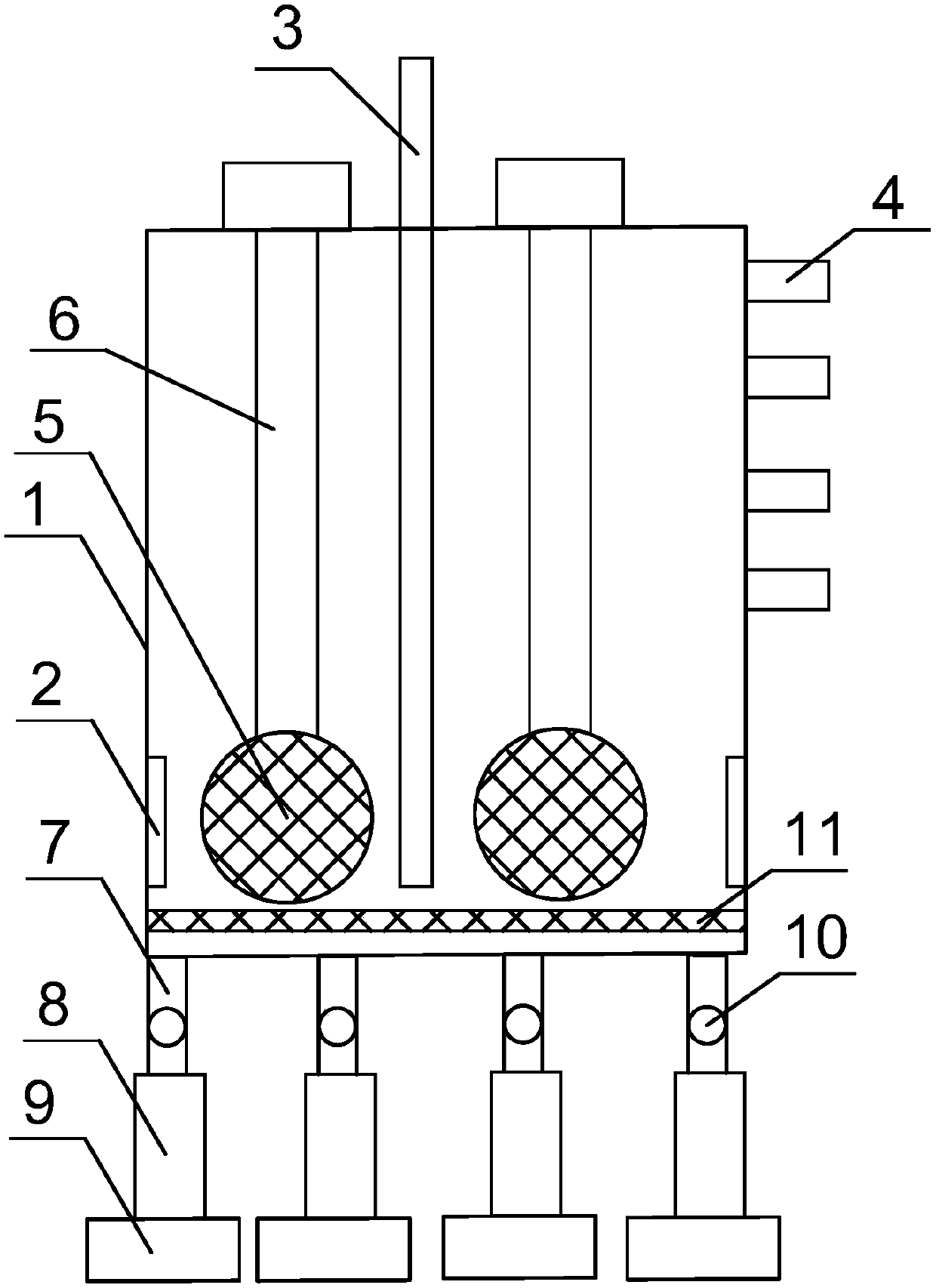

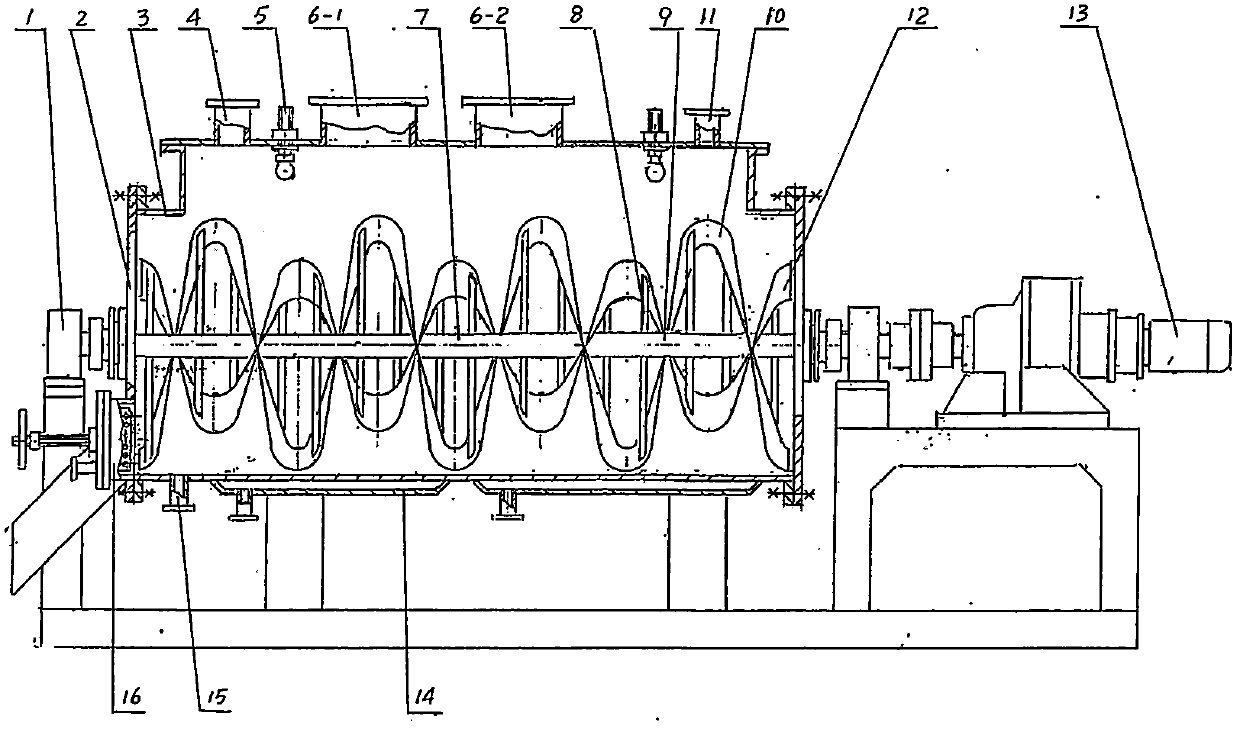

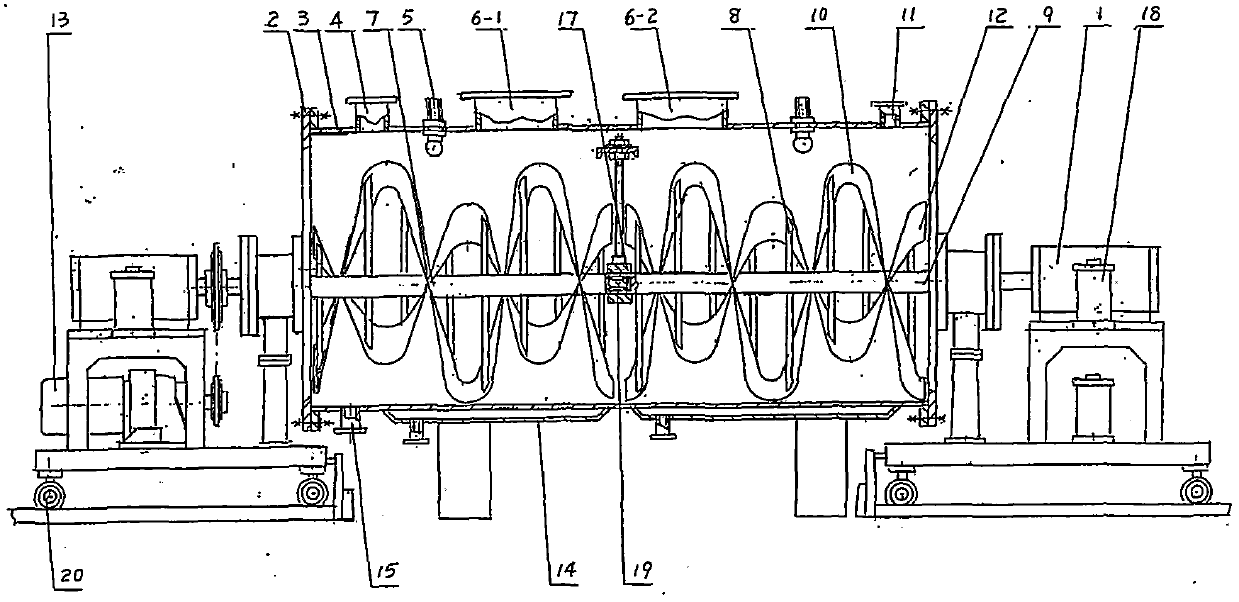

Ectopic leaching restoring device and restoring method for chromic slag polluted soil

ActiveCN102601106AContinuous operationRealize emergency handlingContaminated soil reclamationAutomatic controlSlag

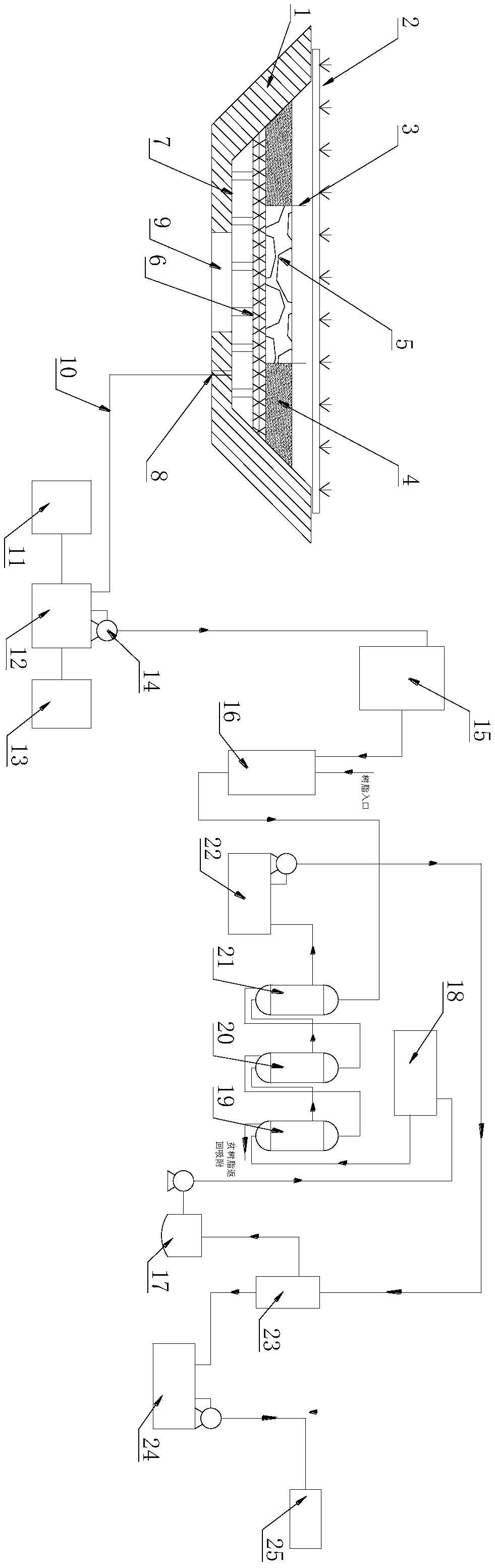

The invention relates to an ectopic leaching restoring device and a restoring method for chromic slag polluted soil. The device is provided with an integrated soil leaching and dewatering system and mainly comprises a feeding system, a soil leaching-dewatering system, a waste gas treating system, an elution collecting treating system and an automatics control system. The chromic slag polluted soil firstly enters a reaction tank leaching section through the feeding system; a chrome-containing component in the soil is transferred into a liquid phase of a leaching agent; the liquid phase is rotated following a spiral stirring thruster; a muddy water mixture is conveyed into a reaction tank dewatering section; the filtrate is discharged through a tank wall with a water-permeable filtering function; the remained soil is conveyed to a mud discharging device following the rotating of the spiral stirring thruster; and lastly, the soil after being leached and dewatered is discharged. The device provided by the invention has the advantages that a power source is utilized to realize the soil leaching and muddy water separating, the energy consumption is low, the structure is simple, the use is convenient, the treating efficiency is high, and the purified degree of the polluted soil after being treated by using the device is above 85%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

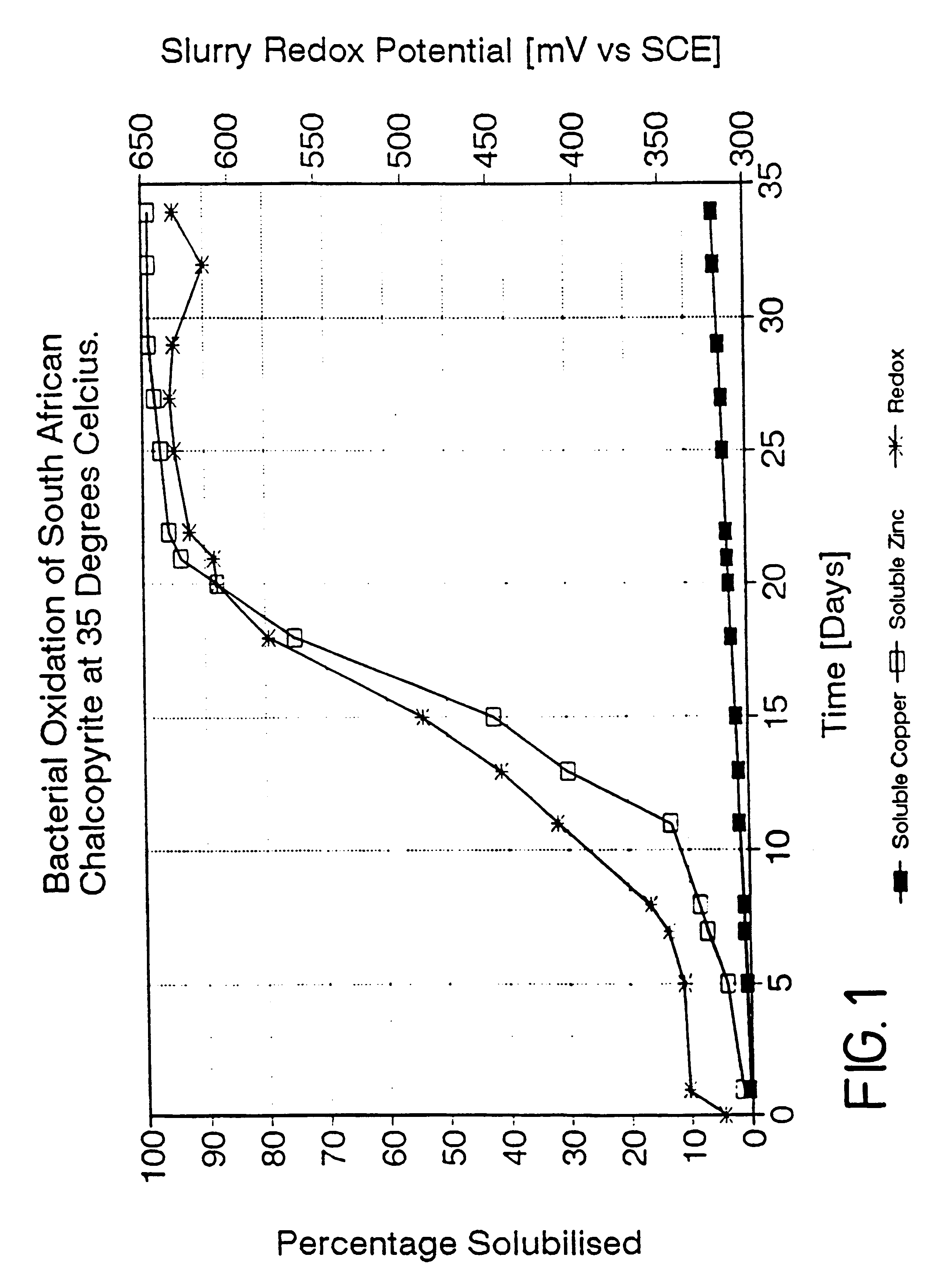

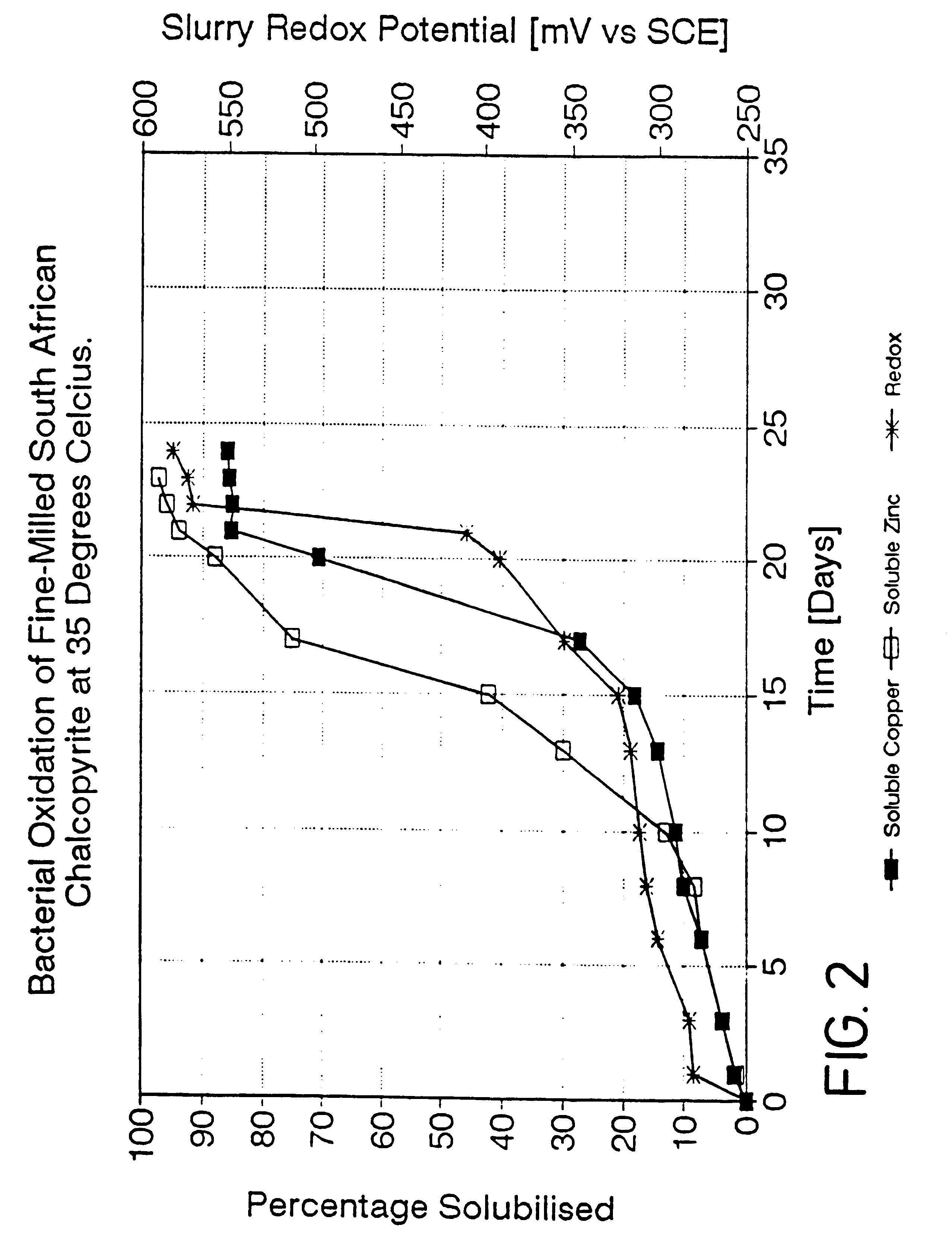

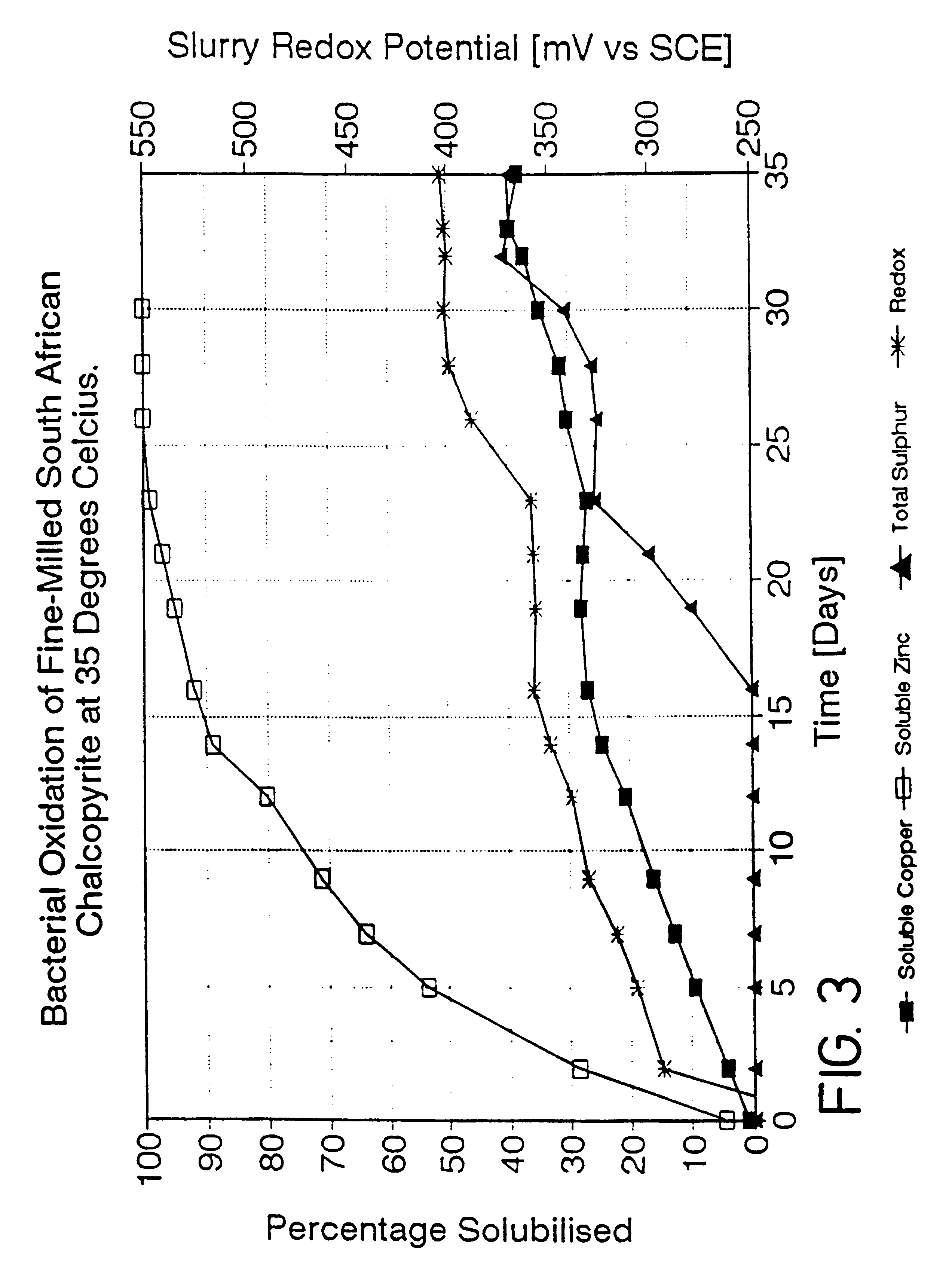

Process for the rapid leaching of chalcopyrite in the absence of catalysts

InactiveUS6277341B1Increase surface areaImprove misalignmentSolvent extractionGold compoundsPregnant leach solutionChalcopyrite

Owner:MINTEK

Method for crushing high mud content adhesive material

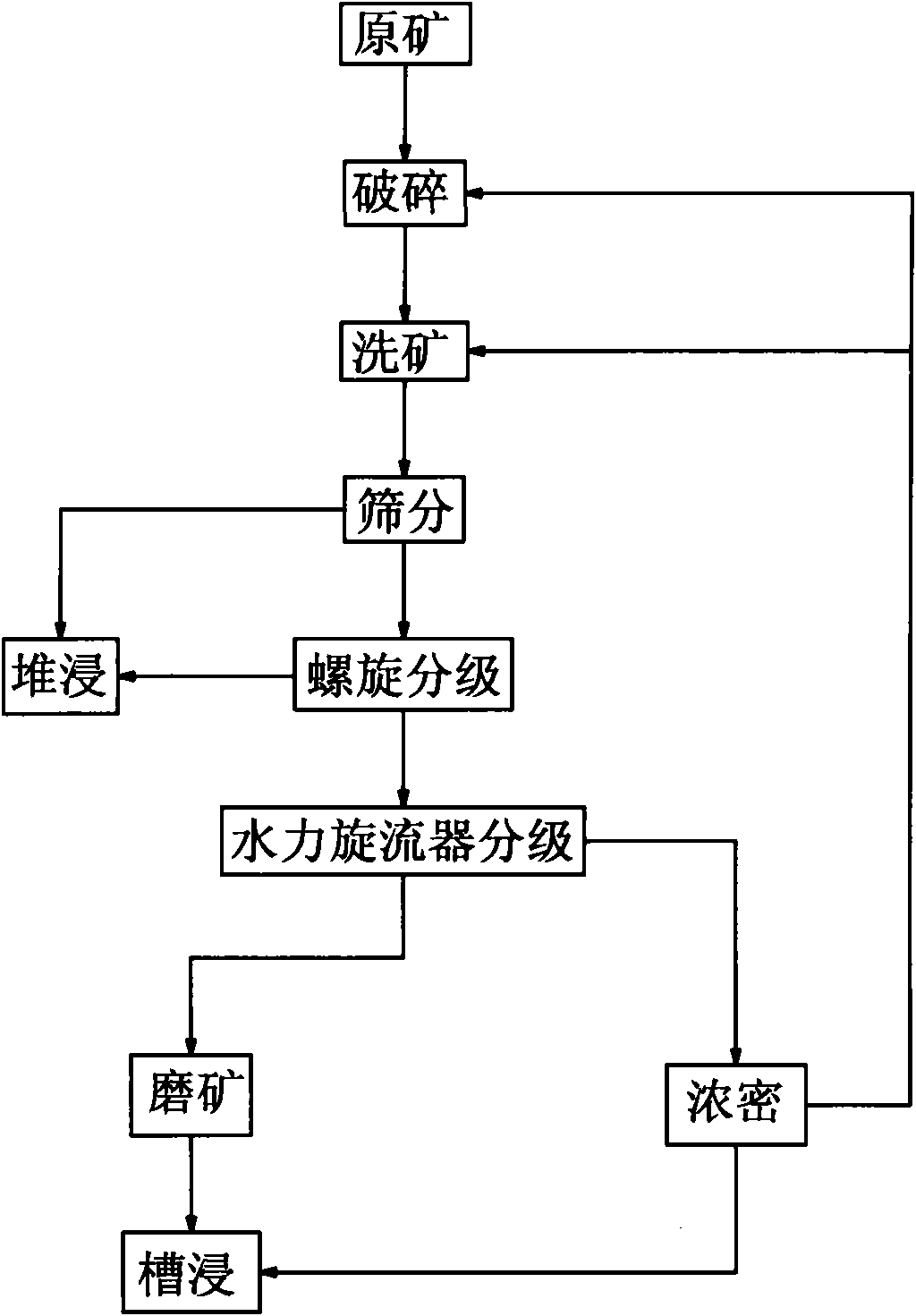

The invention relates to a method for crushing a high mud content adhesive material, comprising the following steps: crushing: crushing mud-containing adhesive material raw ores while flushing by flushing liquor; washedore: using washedore liquor to wash the crushed ores; fineness classification: performing fineness classification into coarse grain ores and fine grain ores, and dump-leaching the coarse grain ores; hydraulic classification: classifying fine grain ores by a hydroclone into overflow and underflow, enabling the underflow to enter tank leaching operation after ore grinding and the overflow to enter a thickening tank; and thickening separation: performing thickening separation in the thickening tank and dividing into underflow and overflow, enabling the underflow to enter the tank leaching operation after ore grinding, enabling the overflow to go back to step 1 as flushing liquor or the step 2 as washedore liquor partially or completely.

Owner:厦门紫金矿冶技术有限公司

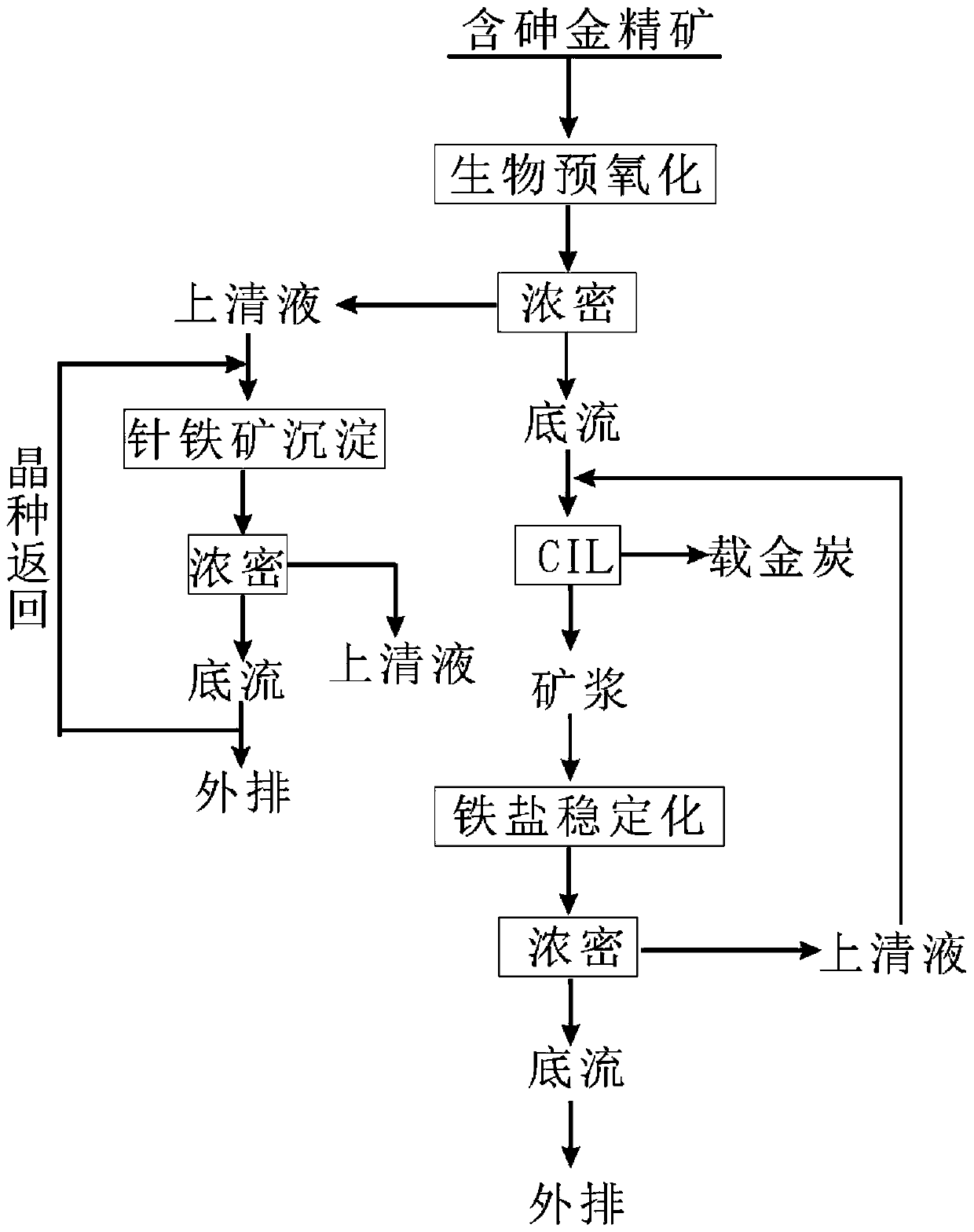

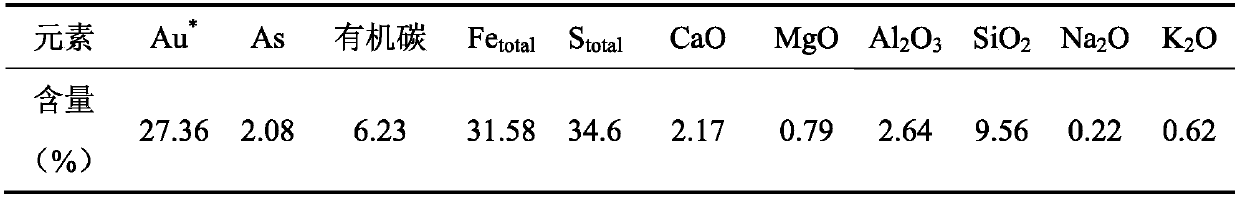

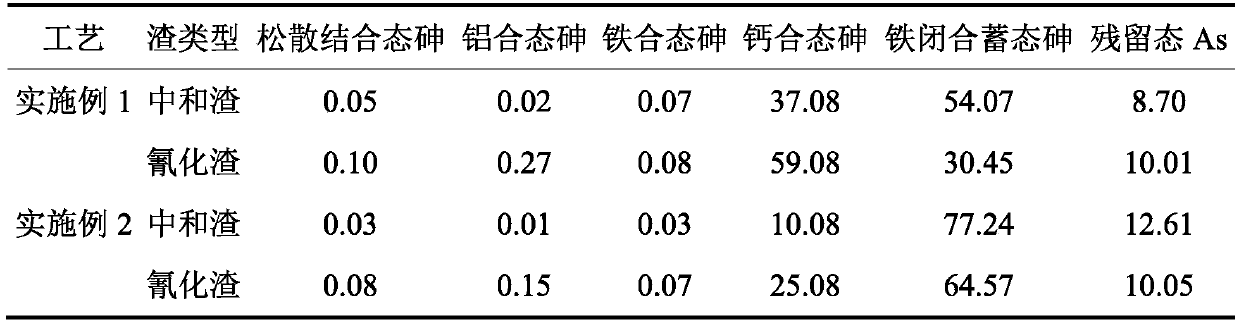

Harmless treatment method of arsenic-bearing slag liquid of biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate

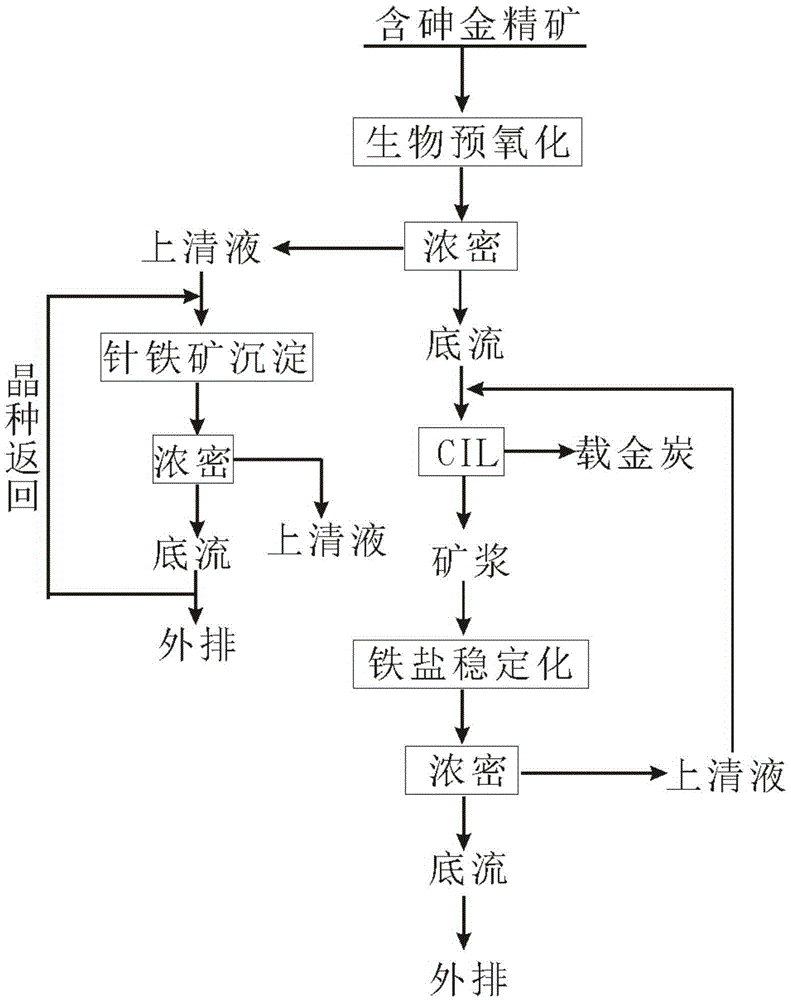

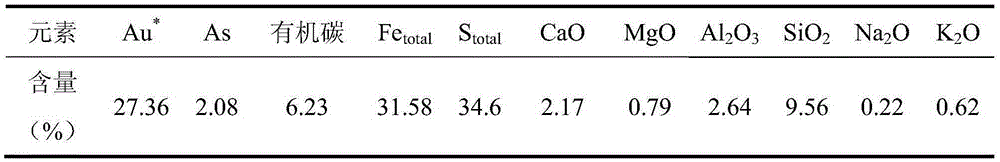

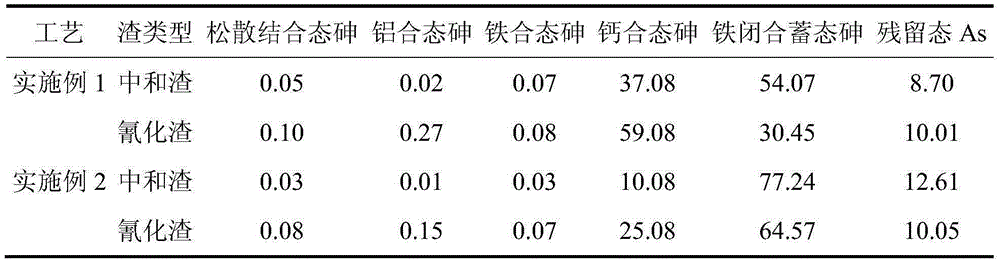

The invention discloses a harmless treatment method of arsenic-bearing slag liquid of the biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate. The method includes the steps of firstly, pre-oxidizing the arsenic-bearing gold concentrate with a biological tank leaching process to obtain pre-oxidized ore pulp; secondly, performing solid-liquid separation on the pre-oxidized ore pulp to obtain first supernate and first underflow; thirdly, pre-neutralizing the first supernate, and performing solid-liquid separation on the pre-neutralized first supernate to obtain second supernate and second underflow; fourthly, performing goethite iron precipitation and arsenic fixing on the second supernate for 2-4 hours, and then performing solid-liquid separation to obtain overflow liquid and third underflow, allowing the overflow liquid to enter the biological tank leaching process, allowing part of the third underflow serving as seed crystal to return to the reaction device of the iron precipitation and arsenic fixing, and discharging the rest of third underflow; fifthly, performing cyanidation carbon-in-pulp leaching on the first underflow to obtain ore pulp; sixthly, performing ferric salt aeration arsenic fixing on the ore pulp obtained in the fifth step. The method provides necessary technical support for the environment-friendly, efficient and low-cost development of the arsenic-bearing gold concentrate.

Owner:厦门紫金矿冶技术有限公司

Tank leaching type steel room-temperature degreasing agent and production method thereof

The invention discloses a tank leaching type steel room-temperature degreasing agent. The raw materials of the degreasing agent comprise the following components by weight percent: 1-4.5% of potassium hydroxide, 35-45% of potassium carbonate, 12-26% of potassium citrate, 1-6.5% of sodium metasilicate pentahydrate, 1-9% of sodium tripolyphosphate, 1-6% of surfactant special for soaking and degreasing, 1-6% of strong-base-resisting surfactant special for soaking and degreasing, 0.1-1.0% of penetrating agent JFC and 1-6% of organosilicon washing agent. The production method comprises the following steps: starting a stirrer, slowly adding potassium hydroxide, potassium carbonate, potassium citrate, sodium metasilicate pentahydrate and sodium tripolyphosphate in the stirrer in sequence, and evenly stirring; and then slowly adding the surfactant special for soaking and degreasing, the strong-base-resisting surfactant special for soaking and degreasing, the penetrating agent JFC and the organosilicon washing agent in the evenly stirred powder material in sequence in a form of streamlet and then further stirring so as to evenly mix the liquid raw materials with the powder raw material, and then discharging and packaging.

Owner:DALIAN SANDAAOKE CHEM

Ectopic leaching restoring device and restoring method for chromic slag polluted soil

ActiveCN102601106BContinuous operationRealize emergency handlingContaminated soil reclamationAutomatic controlSlag

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Universal comprehensive treating agent for performing spraying, tank leaching, ultrasonic wave treatment and wiping on steel workpiece

InactiveCN103726041AGuarantee the construction qualityAchieve cleanabilityMetallic material coating processesChemical treatmentPhosphoric acid

The invention discloses a universal comprehensive treating agent for performing spraying, tank leaching, ultrasonic wave treatment and wiping on a steel workpiece. The universal comprehensive treating agent is characterized by comprising the following raw materials by mass percent: 28-48% of phosphoric acid with the mass concentration of 85%, 1-2% of citric acid, 1-2% of zinc oxide, 1.5-2.5% of nickel nitrate, 1.5-2.5% of sodium tripolyphosphate, 2-4% of ethylene glycol monobutyl ether, 1-3% of a soak degreasing oil-removing special surfactant, 0.1-0.5% of a defoaming agent, and the balance of water. The universal comprehensive treating agent can achieve the purposes of cleaning for degreasing, rust removing, welded oxide skin removing and the like, and can further quickly form a passivated film on the surface of the workpiece, after the passivated film is dried naturally, various paints can be sprayed and painted immediately, the secondary oxidation is avoided, and the painting quality is guaranteed. The whole chemical treatment process is simple, and convenient to operate, and the production cost is greatly lowered.

Owner:DALIAN SANDAAOKE CHEM

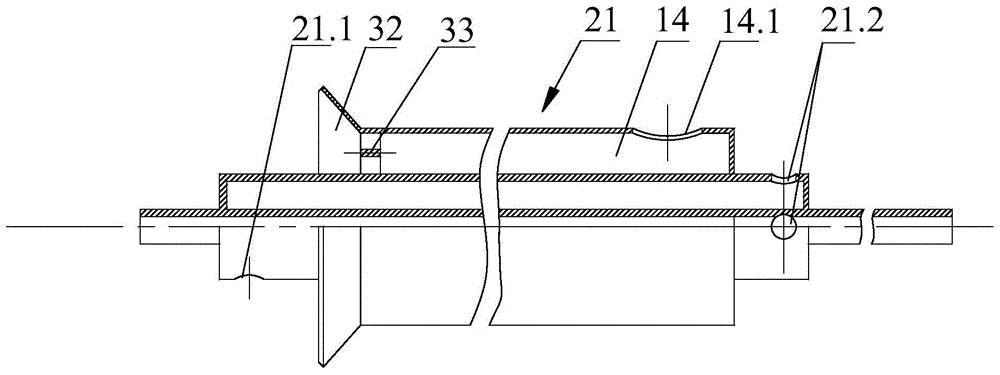

Separation device for active ingredients of natural medicines

InactiveCN107754372AFix extraction issuesFast filteringSolid solvent extractionLiquid tankMagnetic stirrer

The invention discloses a separation device for active ingredients of natural medicines, which comprises an extraction tank, a heating device and a thermometer are arranged at the bottom of the extraction tank, and at least one liquid inlet communicating with the extraction tank is arranged on the side wall of the extraction tank. The inside of the extraction tank is provided with a hollow filter ball, the ball wall of the filter ball is a filter screen, the top of the filter ball is connected with a vertical rotating shaft, and the top of the rotating shaft is connected with a driving device for driving the rotating shaft. A plurality of liquid outlet pipes are arranged under the extraction tank, the top of the liquid outlet pipes is connected with the extraction tank, and the bottom of the liquid outlet pipes is connected with a reaction vessel, and the reaction vessel is placed on a magnetic stirrer. All are provided with a control valve to control the conduction of the liquid outlet pipe. The invention can extract multiple effective components by changing the solvent added into the extraction tank, and solves the problem of extracting the effective components from peach leaves.

Owner:成都福尔斯特医药技术有限公司

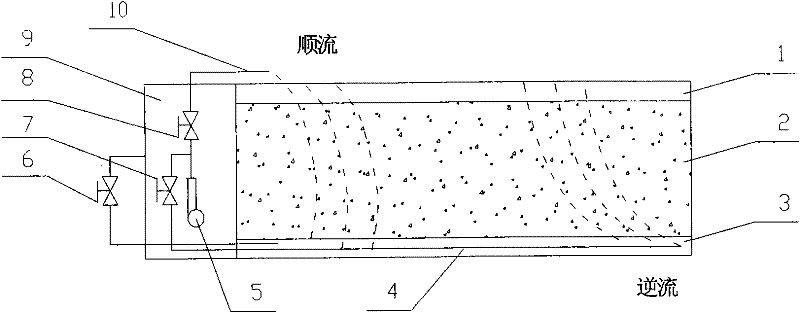

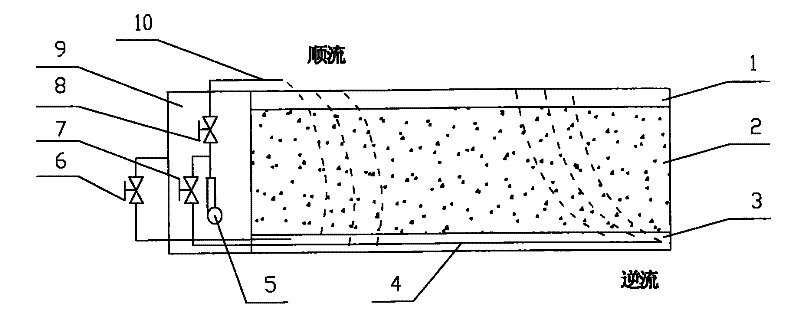

Liquid distributing method in tank leaching process

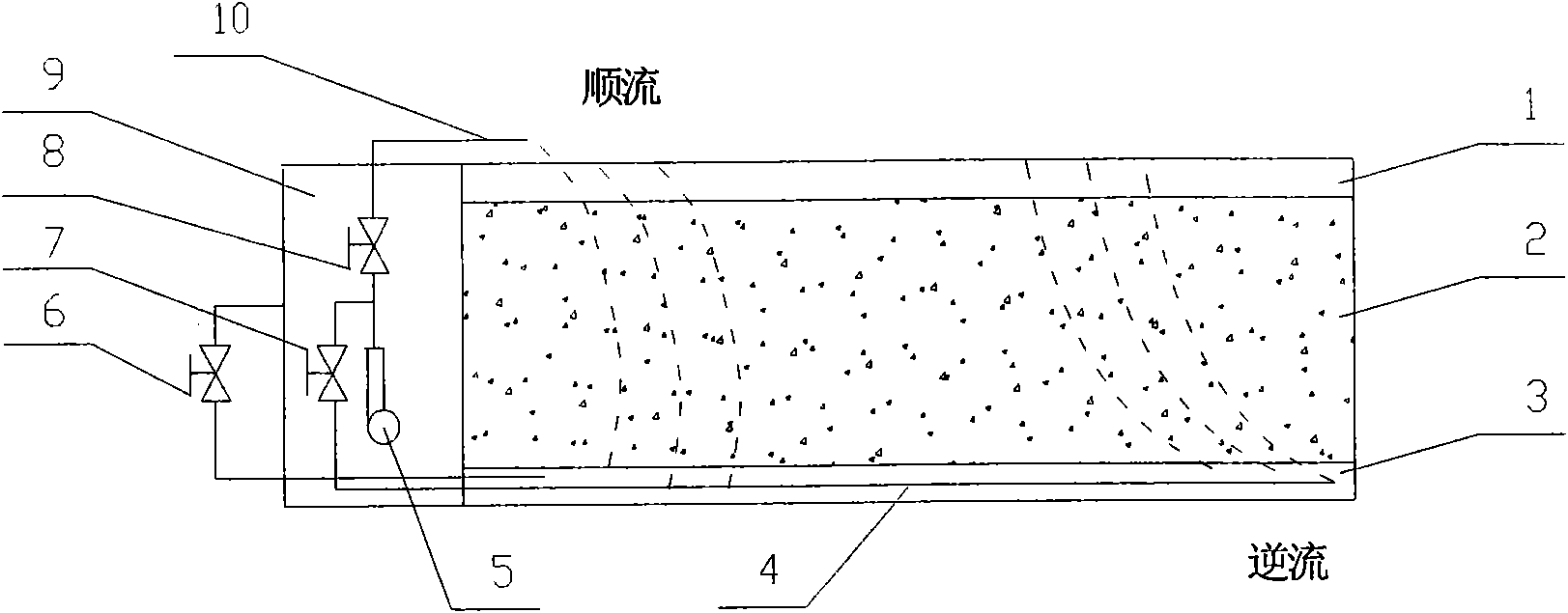

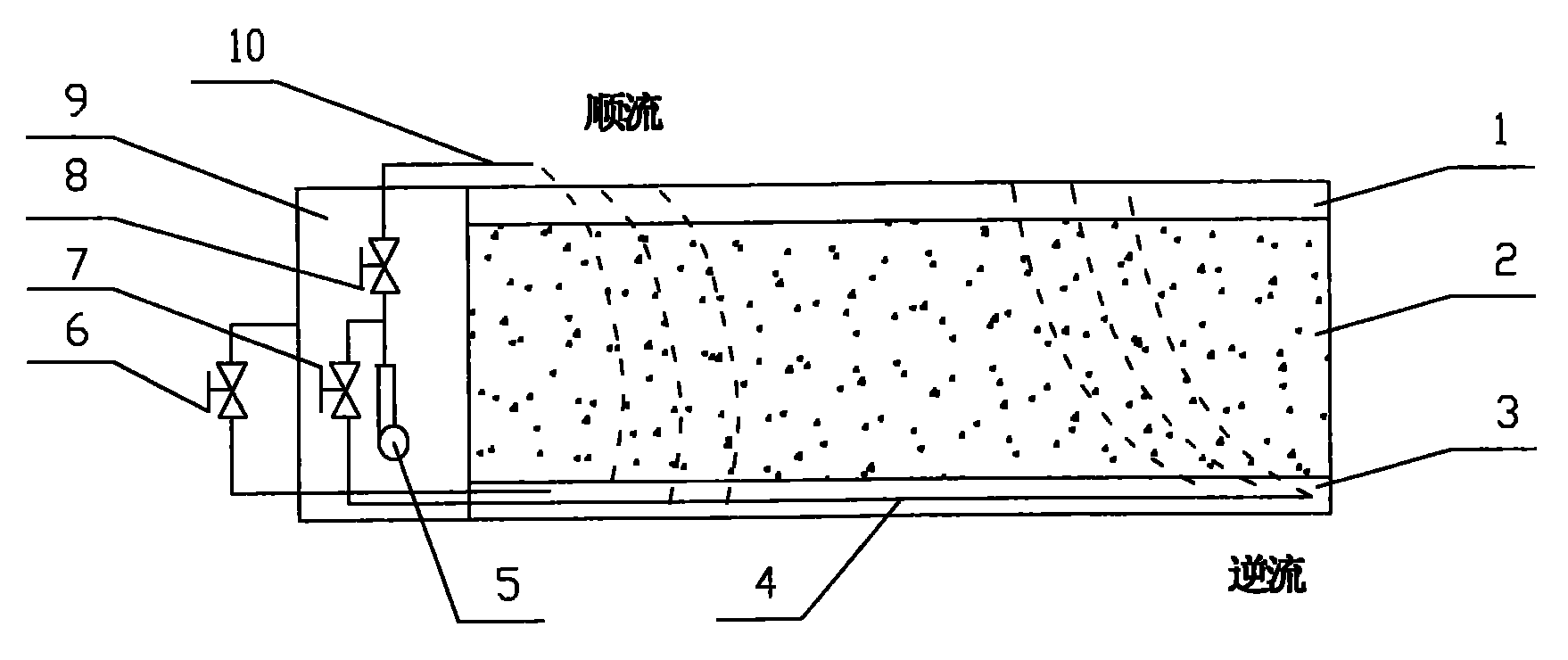

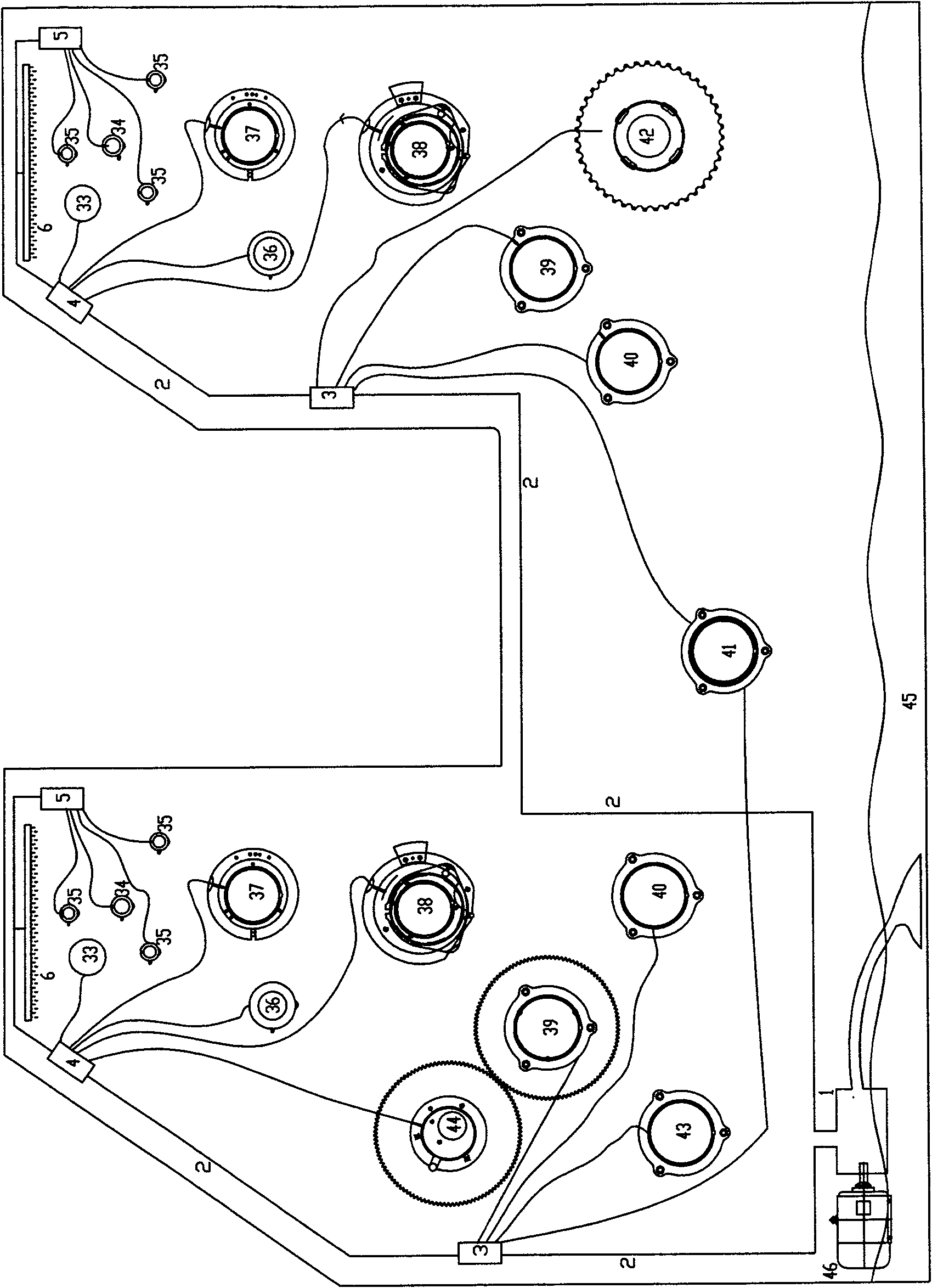

InactiveCN101857916AAvoid gatheringEasy to operateProcess efficiency improvementMaterials scienceCounter current

The invention belongs to the field of special exploration of metal mines, and relates to a liquid distributing method in a tank leaching process, which is suitable for infiltration tank leaching of various ores. In the invention, a counter current liquid distributing mode is added on the basis of a traditional down-flow liquid distributing mode, i.e. a process that infiltration solution enters an ore bed from the bottom of a tank is adopted, the leaching solution slowly infiltrates upwards, and flows out from the top of the tank. The infiltration direction is periodically changed through controlling a ball valve, and the counter current liquid distributing mode and the down-flow liquid distributing mode are alternatively used to realize a combined liquid distributing mode. The novel liquid distributing mode can avoid the blocking phenomenon of on a false bottom structure, which is caused by fine granules, improves the leaching efficiency, and has the advantages of simple operation, convenient management as well as easy generalization and application.

Owner:UNIV OF SCI & TECH BEIJING +2

Fixed point injection positioning sprinkling type lubricating system for offset press

InactiveCN100564990CHarmonious and orderly operationGuaranteed to workRotary lithographic machinesEngine lubricationStart timeInjection point

Fixed-point injection and positioning spray lubrication system of offset printing machine, including transmission shaft sleeves and gears in the isolation room on both sides of the machine case, lubricating oil circuit in the isolation room, lubricating oil route in the oil storage tank at the bottom of the isolation room, and in the isolation room It is composed of the oil spray tank on the top, the oil supply main pipe and the oil pump connected between the oil storage tank and the oil spray tank, the diverter connected in series between the oil supply main pipe, and the shunt pipe connected between the output end of the diverter and one end of the moving shaft. The graded injection lubrication system is adopted to achieve the effect of distributing lubricating oil according to the required amount. A spray box is installed on the isolation room, and lubricant can be added to all moving rollers. Especially when the machine has been shut down for a long time and the moving parts are dry, it can prevent the phenomenon of jamming caused by sudden start. The invention has the beneficial effects of ensuring the harmonious and orderly operation of the moving parts during the operation of the roller shaft, ensuring stable printing quality, ensuring the normal operation of each moving part when the machine is shut down for a long time, reducing wear and prolonging the mechanical life.

Owner:浙江昌明机械有限公司

Surface tank leaching process for classified heap building

PendingCN111074069AImprove permeabilityImprove seepage capacityProcess efficiency improvementPregnant leach solutionIon exchange

The invention provides a surface tank leaching process for classified heap building. The process comprises the steps as follows: firstly, ore is crushed into different grain grades by a crusher, screening-mixing is performed for grading treatment, and then the treated ore is conveyed into a leaching tank of a surface tank leaching solution reaction device for classified heap building to be subjected to zonal heap leaching; a leaching solution in the liquid preparation tank is pumped to the leaching tank by a supply pump for spraying, spraying distribution is performed in different zones and different intensities, and the leaching solution is conveyed to a solution enriching tank via a solution outlet, pumped to a head tank by a leaching lift pump, and fed into an adsorber from the head tank for ion exchange; elution is performed in a manner of three-tower serial orthoflow, and an eluant is conveyed to the head tank from an eluant preparation tank, and subjected to three-tower serial countercurrent elution at a certain rate to become a qualified solution; and lean resin from the adsorber is returned to the adsorber for recycling, and the qualified solution is pumped to a settling tower for settling, and is finally filtered by a filter press to form the finished product. The process is simple and high in practicality.

Owner:EAST CHINA UNIV OF TECH

Paint spraying and drying process

InactiveCN103846210AReduce use costImprove spraying effectPretreated surfacesCoatingsMechanical equipmentZinc

The invention relates to a paint spraying and drying process. The paint spraying and drying process comprises the following steps: a) oil removal: removing oil stains on the surface of a black metal workpiece during production by using a tank leaching method; b) washing; c) rust removal: removing rust on the surface of steel or iron by using acid and the tank leaching method; d) washing; e) surface conditioning: performing surface treatment before phosphorization by using the tank leaching method; f) phosphorization: phosphorizing the surface of steel or iron by using zinc series phosphorizing solution and the tank leaching method; g) washing; h) drying; i) spraying. The paint spraying and drying process has the advantages that the spraying effect is better through the tank leaching method in all links and proportioning of all components, the paint is not apt to fall; since a special drying process is adopted, the adhering time is especially prolonged and the use cost of mechanical equipment is reduced.

Owner:大连优力特换热设备制造有限公司

Surface treatment process of hub

InactiveCN106367763AImprove toughnessGood quality wheelsMetallic material coating processesEnvironmental engineeringUltimate tensile strength

The invention discloses a surface treatment process of a hub. The surface treatment process comprises the steps of 1, alkaline treatment: treating the surface of the hub through adopting an alkaline cleaning fluid, soaking the hub in the alkaline cleaning fluid to be treated for 30 seconds to 10 minutes at the temperature of 30 to 60 DEG C; 2, water washing; 3, degreasing: treating the hub through adopting a tank leaching method with a KL-13 degreasing derusting additive for 5 to 10 minutes at the temperature higher than 5 DEG C, wherein during utilization, the ratio of the KL-13 degreasing derusting additive to water is 2%; the PH value of a tank solution is 7; 4, water washing; 5, acidic derusting: treating the hub through adopting the tank leaching method with an acidic derusting liquid for 3 to 8 minutes at the temperature of 40 to 50 DEG C, wherein the formula of the acidic derusting liquid is that the acidic derusting liquid comprises technical hydrochloric acid with the concentration of 31% and 3% of a corrosion inhibitor; 6, water washing; 7, phosphating: carrying out phosphating on the surface of the hub through adopting the tank leaching method with a zinc series phosphating solution, wherein a phosphating agent is divided into an A agent-tank solution preparation agent, a B agent-additive and a C agent-accelerant; and 8, water washing. According to the surface treatment process, the hub is high in strength, good in toughness, good in quality, high in processing precision, not liable to deform and high in impact resistance, and the popularization of a product is facilitated.

Owner:KAIPING ZHONGLV IND

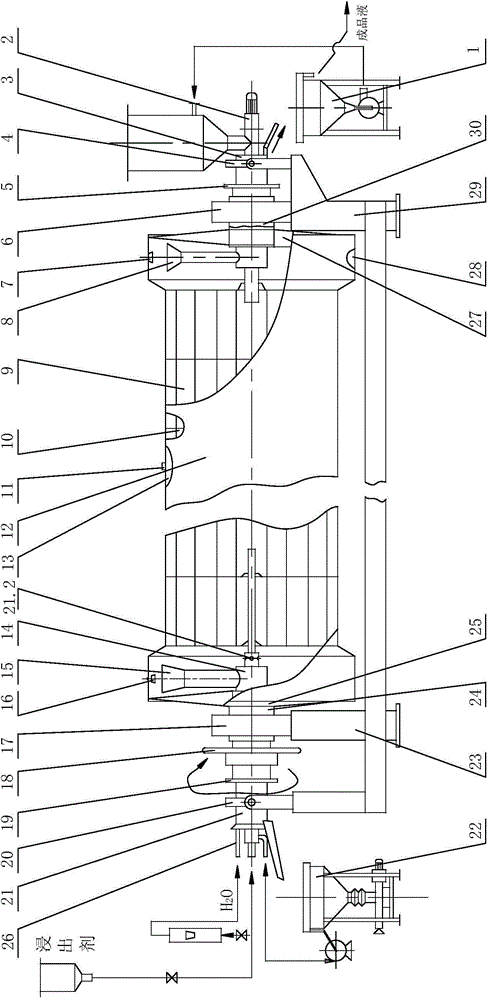

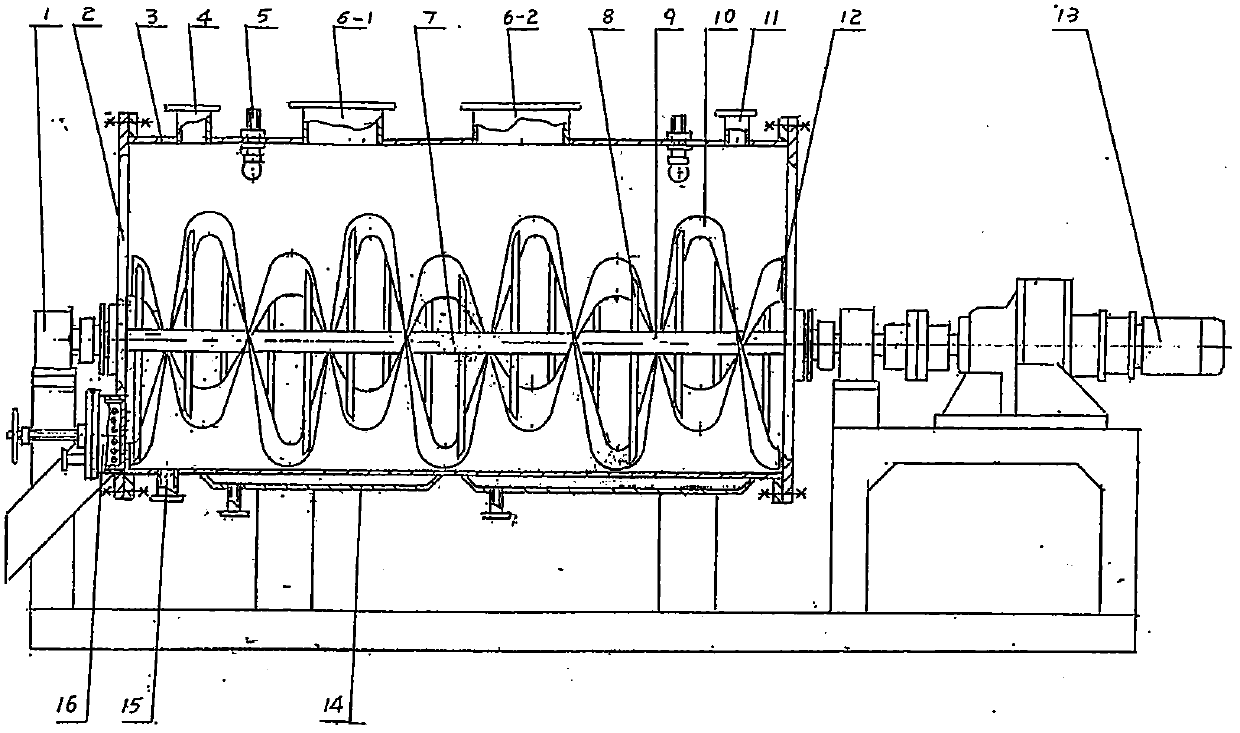

Rotary continuous leaching unit and continuous countercurrent leaching method

ActiveCN104651608ALabor savingReduce power consumptionProcess efficiency improvementHeap leachingMaterials science

The invention discloses a rotary continuous leaching unit and a continuous countercurrent leaching method. According to the method, mineral aggregate is added from one end of a closed tunnel container with stirring function, and is continuously moved to the other end; and a leaching solution is injected from the other end of the tunnel container and is continuously moved in the opposite direction to the movement direction of the mineral aggregate, thereby achieving the goal of continuous countercurrent leaching. The practical equipment is an aggregate unit composed of a rotary leaching chamber, a head thickening machine, a tail thickening machine and a matched system. The method and unit disclosed by the invention are used instead of the traditional technique and equipment based on heap leaching, tank leaching, multistage countercurrent vat leaching or the like, thereby implementing continuous high-efficiency operation, simplifying the equipment configuration, adapting to multiple different grades of mineral aggregate, and achieving the goals of energy and manpower saving and environment friendliness.

Owner:薛平 +1

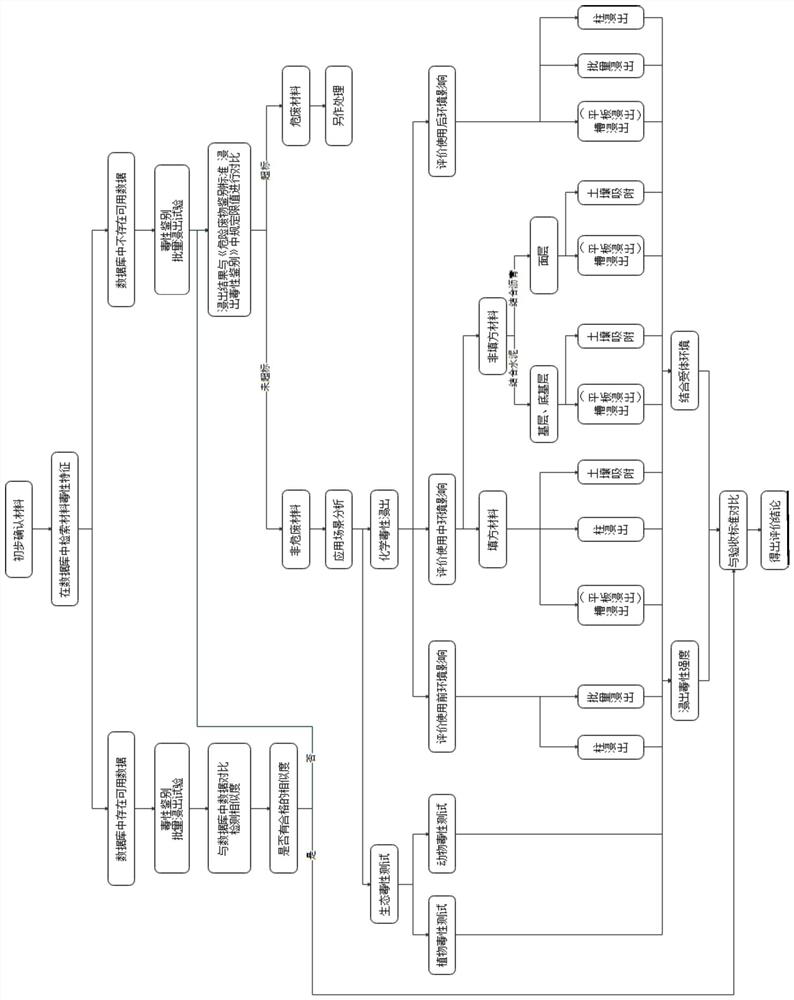

Environmental impact evaluation method for road backfilling by using renewable solid waste material

ActiveCN112129614AEffectively evaluate environmental impactMaterial analysis using wave/particle radiationSolid waste managementPregnant leach solutionEnvironmental engineering

The invention provides an environmental impact evaluation method for road backfilling by using a renewable solid waste material. The method comprises the following steps of: confirming the material, and retrieving material property characteristics in an information base; identifying the toxicity of the material, and judging the availability of the material; if the material is available, performingchemical toxicity analysis and ecological toxicity test, wherein the chemical toxicity analysis comprises analysis of application scenes of the material, and the environmental characteristics of thematerial before use, in use and after use are respectively evaluated by performing column leaching, batch leaching, tank leaching, soil adsorption and other tests on the material; the ecological toxicity test comprises the steps of observing the toxicity of the material or leachate thereof to the tested species to evaluate the environmental impact of the material; and comparing the results of thechemical toxicity analysis and the ecological toxicity test and the local receptor environment with the acceptance standard to obtain the material environmental impact evaluation conclusion. The method provided by the invention effectively evaluates the environmental impact caused by the renewable aggregate, and provides a reference for the environmental impact evaluation means and method generated by resource utilization of the renewable material in engineering.

Owner:ZHEJIANG UNIV OF TECH

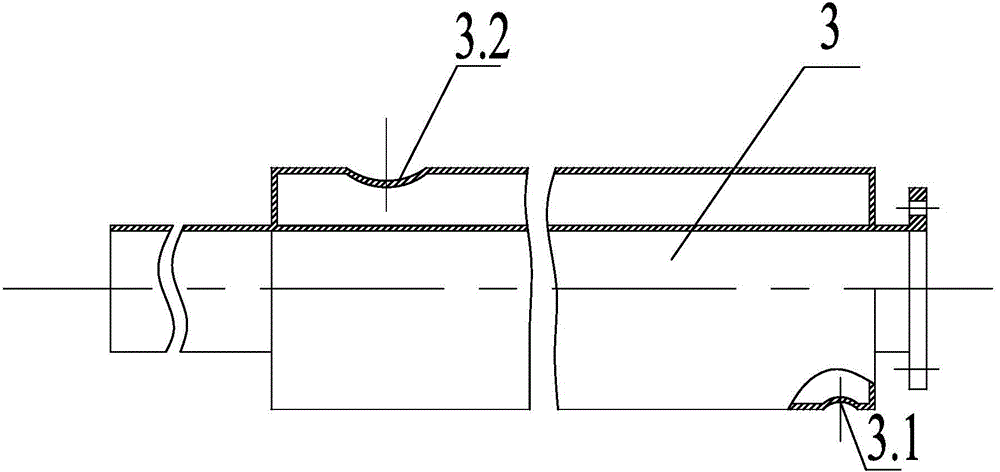

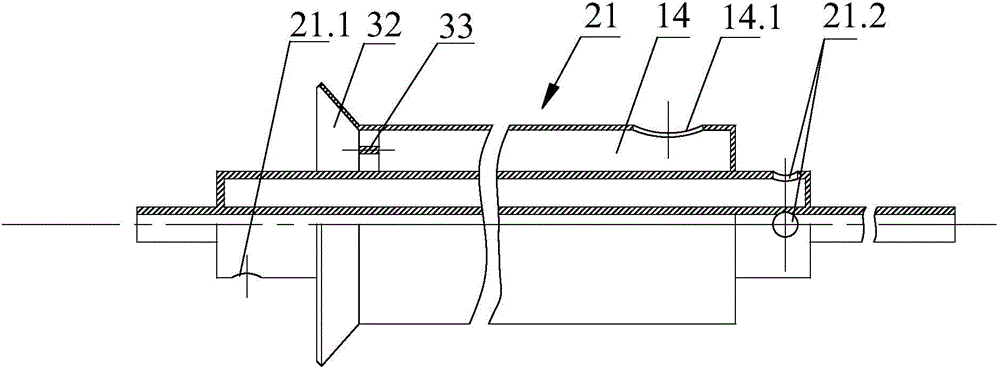

Horizontal spiral stirring leaching tank and tank group and leaching method thereof

ActiveCN109646990ALarge specific surface areaFully contactedCounter-current extractionSolid solvent extractionElutionEconomic benefits

The invention relates to a horizontal spiral stirring leaching tank and a tank group and a leaching method thereof, and belongs to the technical field of extraction and production of natural medicines. The stirrer of the leaching tank adopts a double-layer spiral belt structure, and the directions of solid-phase particles in feeding liquids turned and pushed by inner ring and outer ring spiral belt blades are opposite, so that a liquid-phase solvent is fully contacted with the surface of the solid-phase particles for friction elution. A tank group counter-current centrifugal leaching method with appropriate crushing degree and lower heating temperature is selected, multi-stage countercurrent leaching and interstage sufficient solid-liquid separation are performed, a former tank leaching solution is used as a later tank leaching solvent for alternate use, a large amount of solvent are saved, the subsequent production load is reduced, and under the condition of keeping and constantly creating a concentration difference, a diffusion boundary layer is thinner or faster to renew, so that the leaching production yield is high, the product quality is good, the cost is low, the economic benefit is good, and GMP standard requirements such as thorough cleaning of equipment and in-batch leached products can be met.

Owner:赵履祥

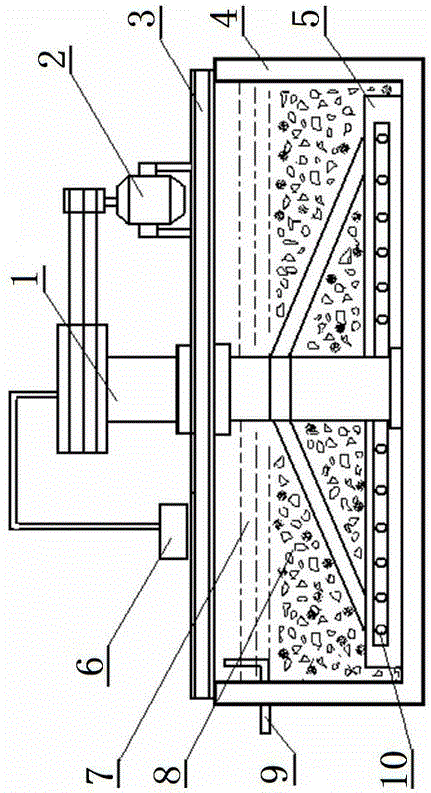

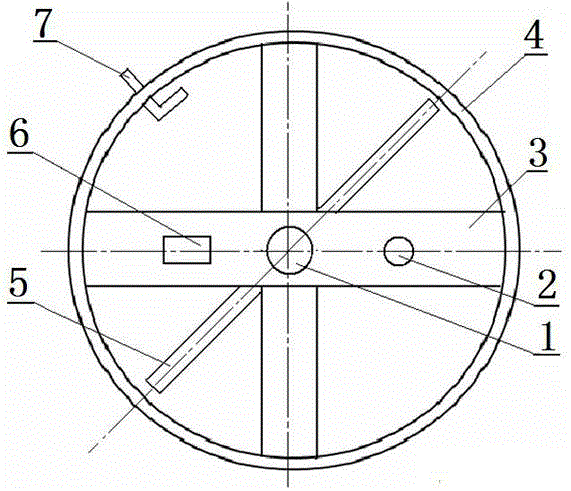

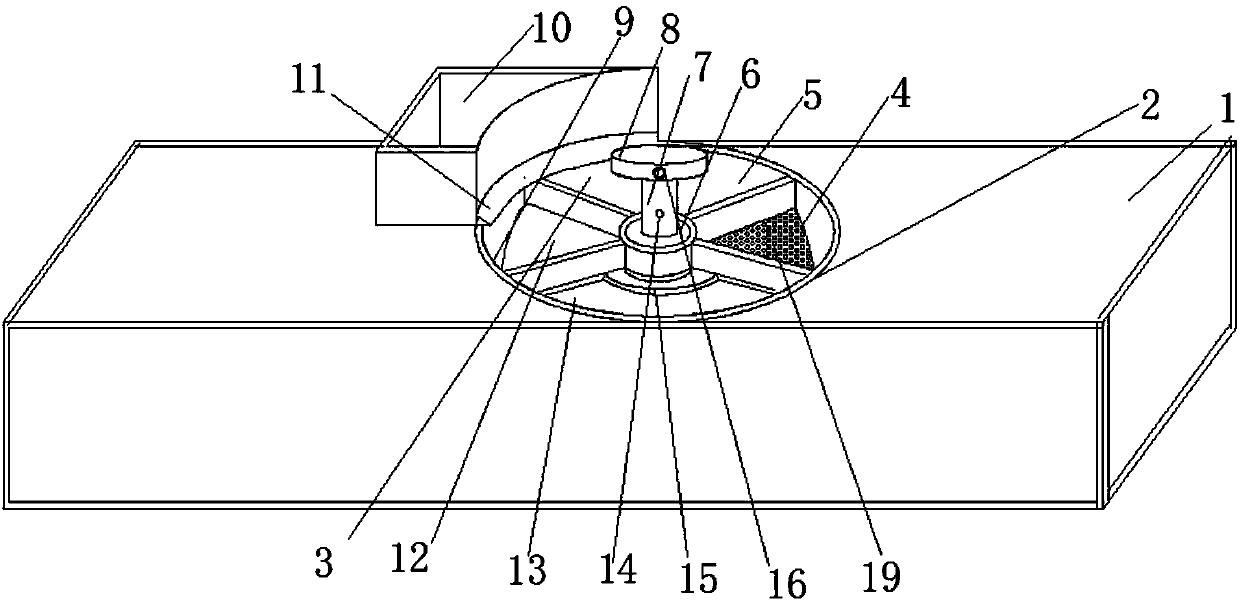

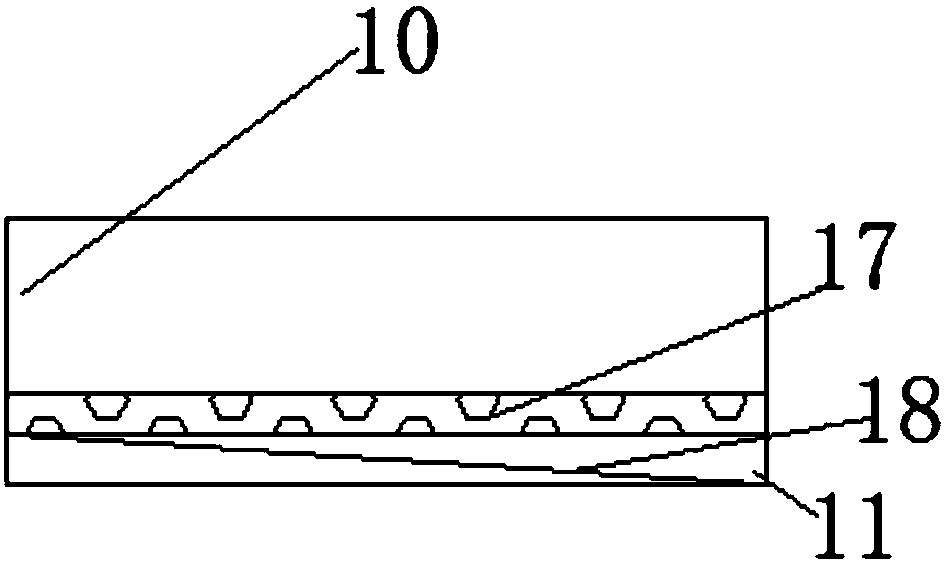

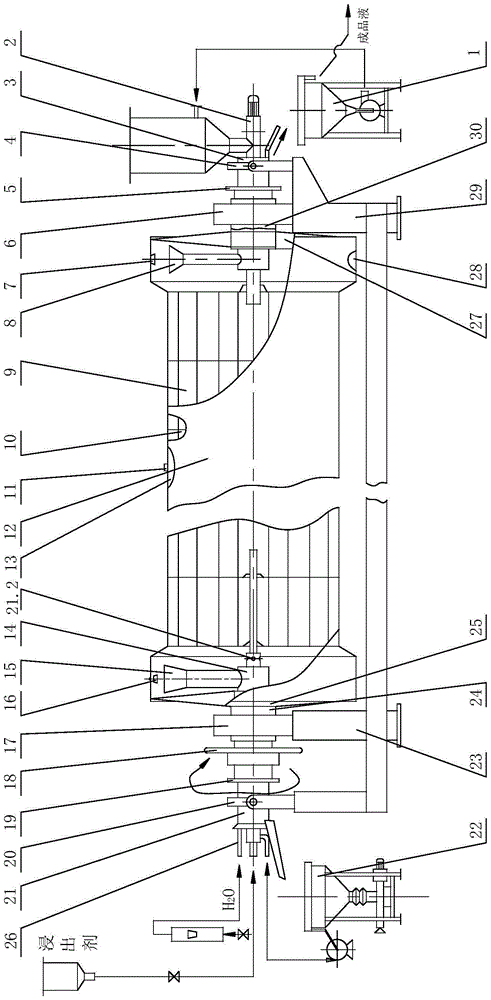

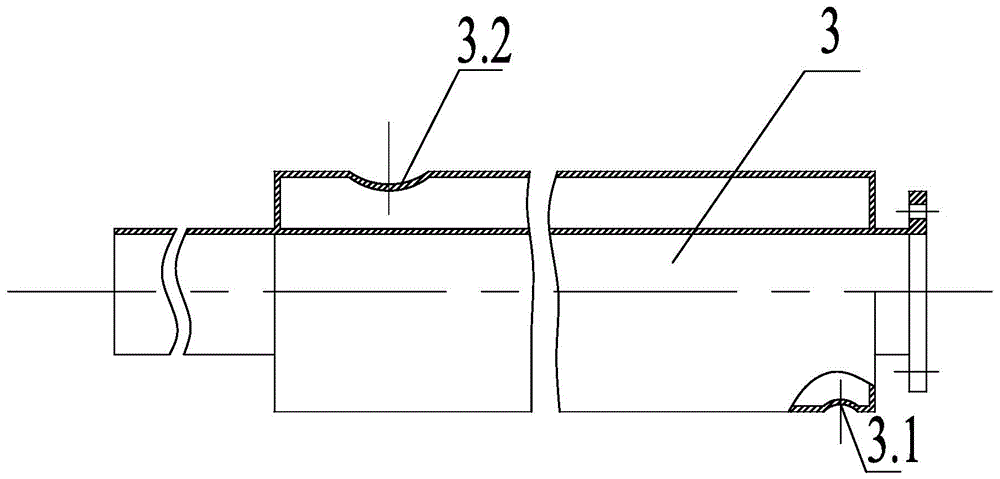

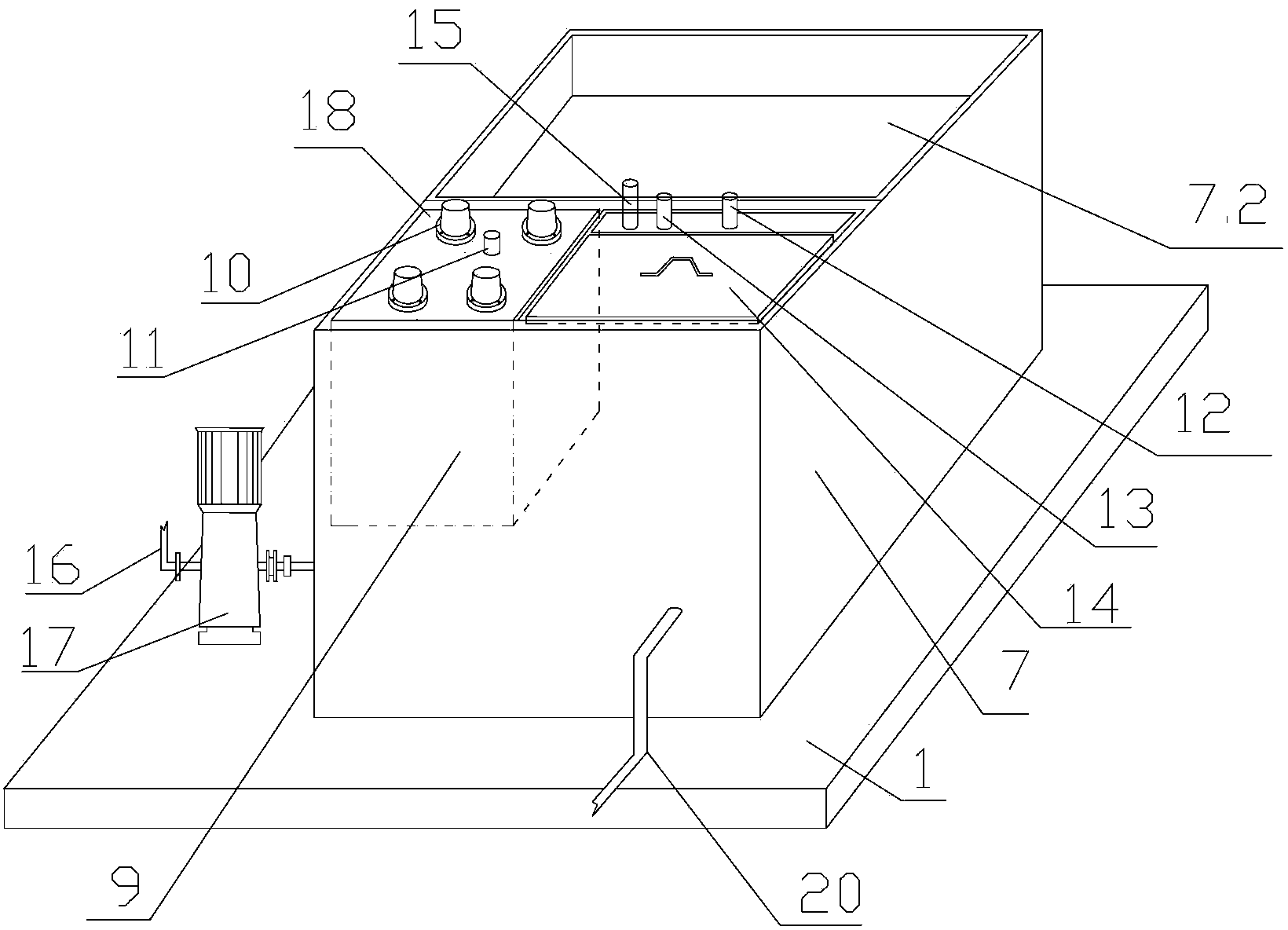

Fast tank leaching test apparatus and application method thereof

InactiveCN104451142AFully contactedDissolution rate is fastProcess efficiency improvementPregnant leach solutionEnvironmental engineering

The invention discloses a fast tank leaching test apparatus and an application method thereof. The fast tank leaching test apparatus comprises a tank body (4), a speed-variable stirring device arranged in the tank body (4), a gas-filling device connected to the speed-variable stirring device and arranged at the bottom of the tank body (4) and a draining device arranged on the wall of the tank body (4). Through low-speed stirring, the fast tank leaching test apparatus allows minerals in the tank to completely contact leaching agent; through enhanced gas filling, dissolution speed of gold is accelerated. According to the fast tank leaching test apparatus, the disadvantage that the test period of a traditional test apparatus is lengthy is overcome, and reference indexes for the leaching rates of heaping leaching and tank leaching of the minerals can be rapidly provided for mine enterprises. The fast tank leaching test apparatus is fast and convenient in parameter adjustment, reliable in operation, simple in structure, and convenient and safe to operate.

Owner:河南省岩石矿物测试中心

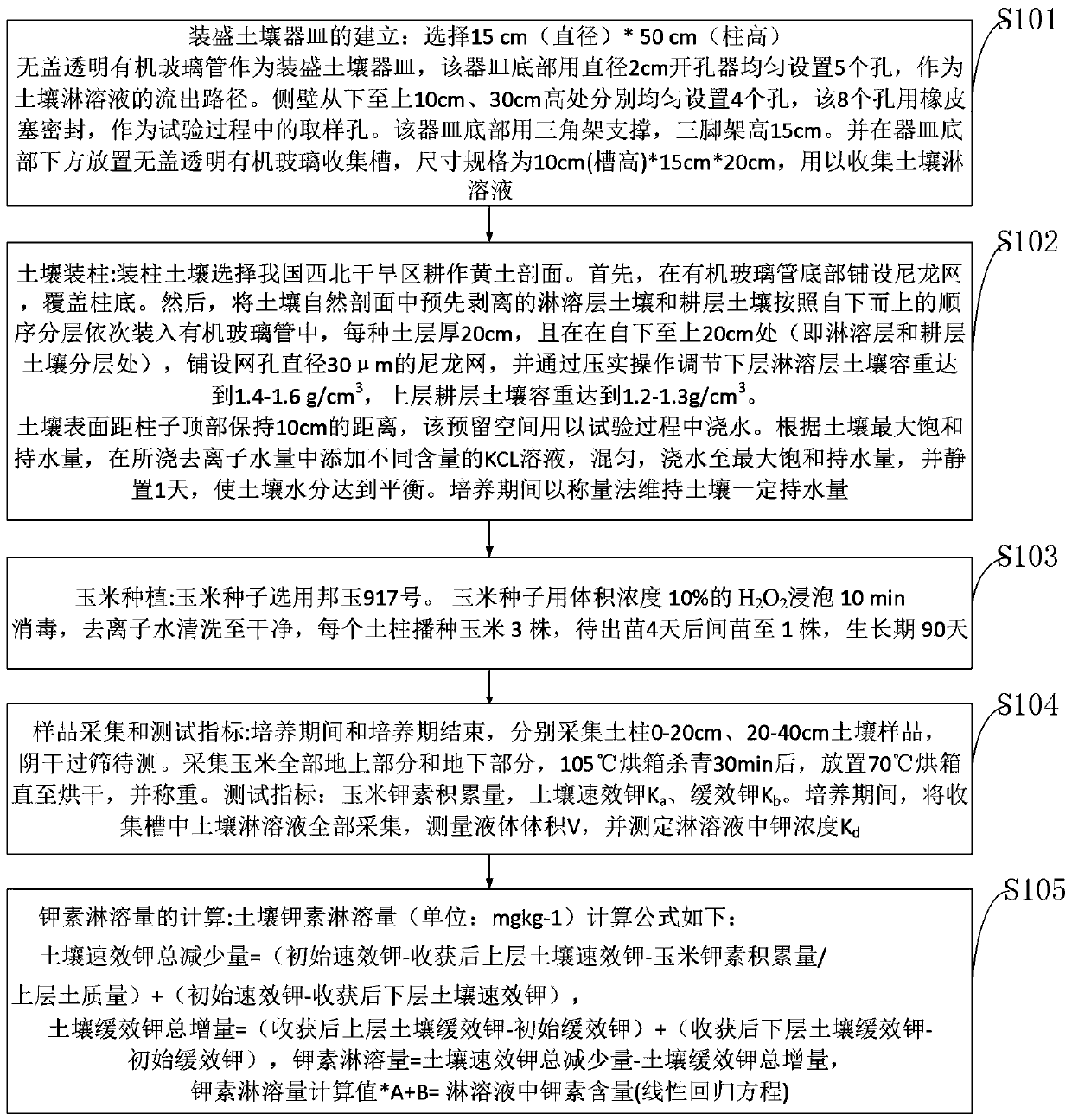

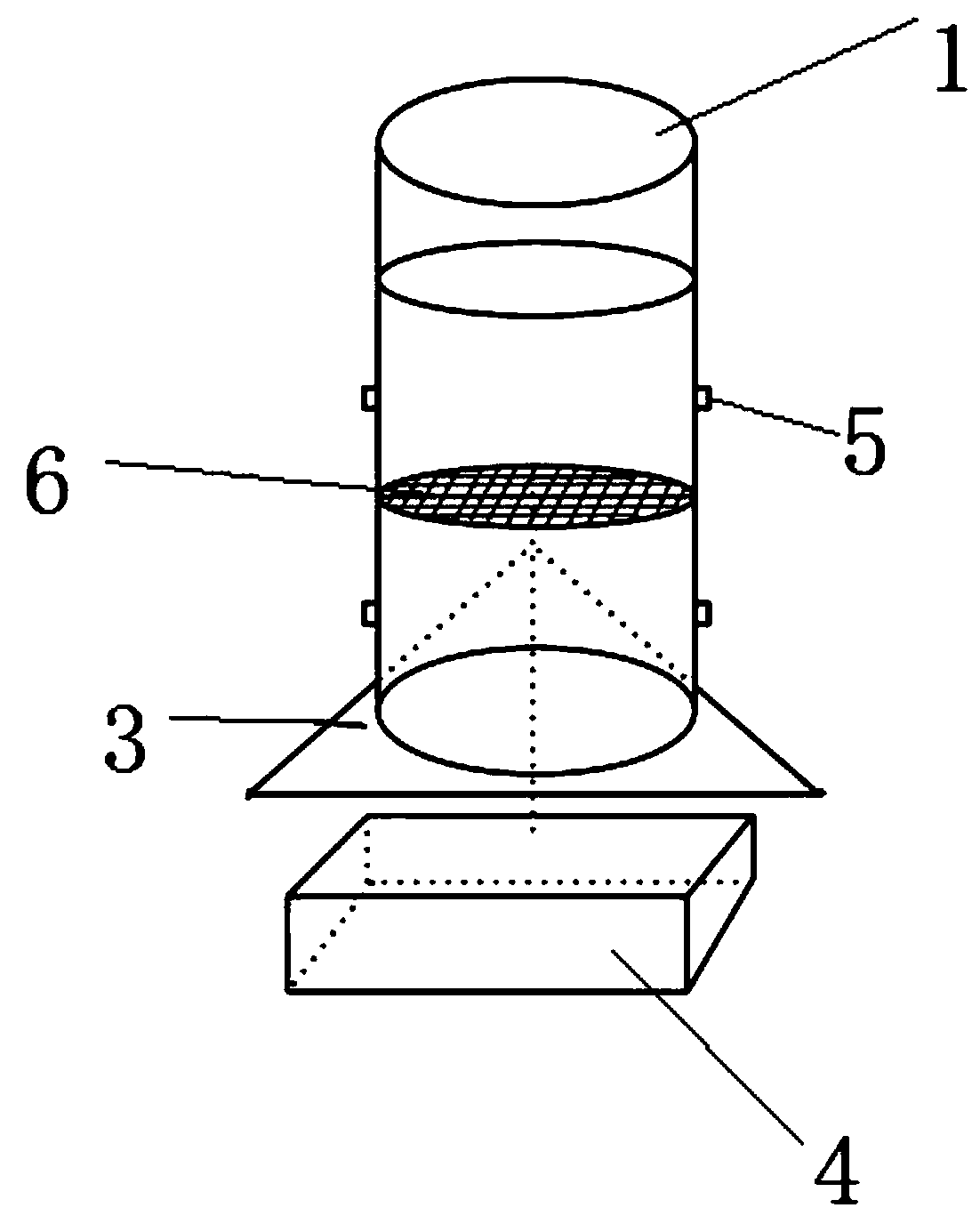

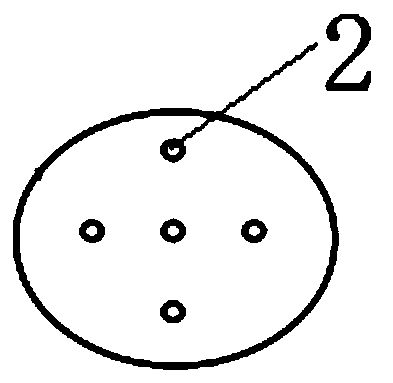

A method and device for short-term determination of soil potassium leaching amount

The invention belongs to the technical field of soil measurement and discloses a method and device for short-term measurement of soil potassium leaching amount. Through the establishment of soil containers, soil packing, corn planting, sample collection and testing, and leaching amount determination, Calculation and other steps to achieve short-term determination of soil potassium leaching amount; a sample collection device for short-term determination of soil potassium leaching amount. The organic glass column includes a filtrate collection tank, a tripod and a vertical compartment root box. The filtrate collection The tank is placed under the plexiglass column, and all the leaching solution in the collection tank is transferred to the solution to be tested. The cross section of the tripod is an equilateral triangle, and the height of the tripod is 15cm. The plexiglass column is formed into a vertical compartment root box by laying a nylon net. The present invention tests the linear correlation between the potassium content in the collection tank leaching solution and the calculated potassium leaching amount through the calculation formula and linear regression equation of the potassium leaching amount, so as to monitor and evaluate the leaching of soil potassium. Provide scientific data.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

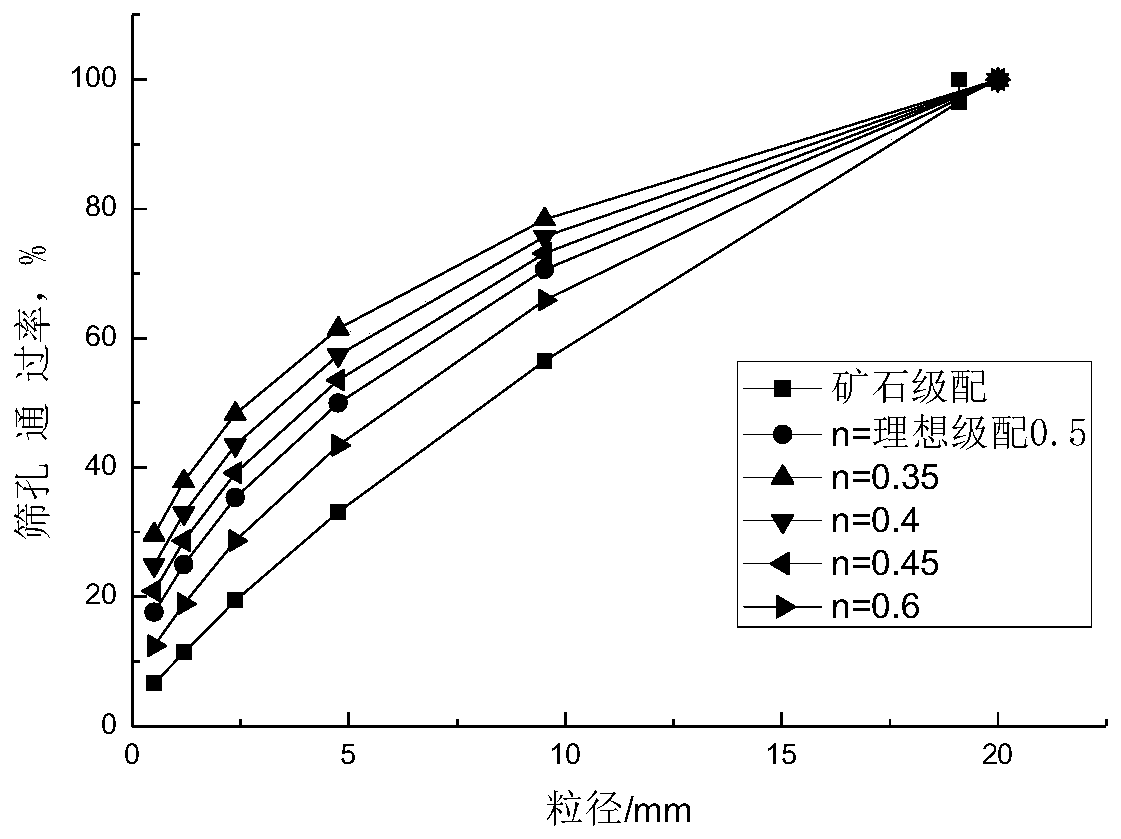

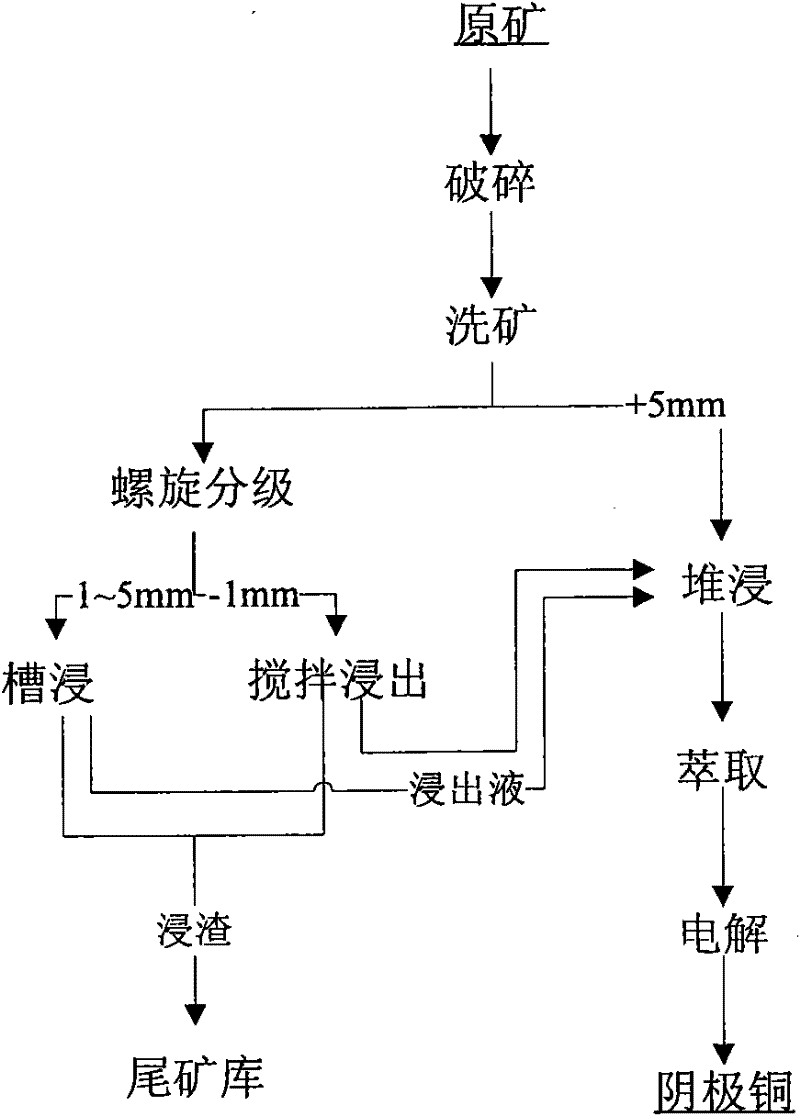

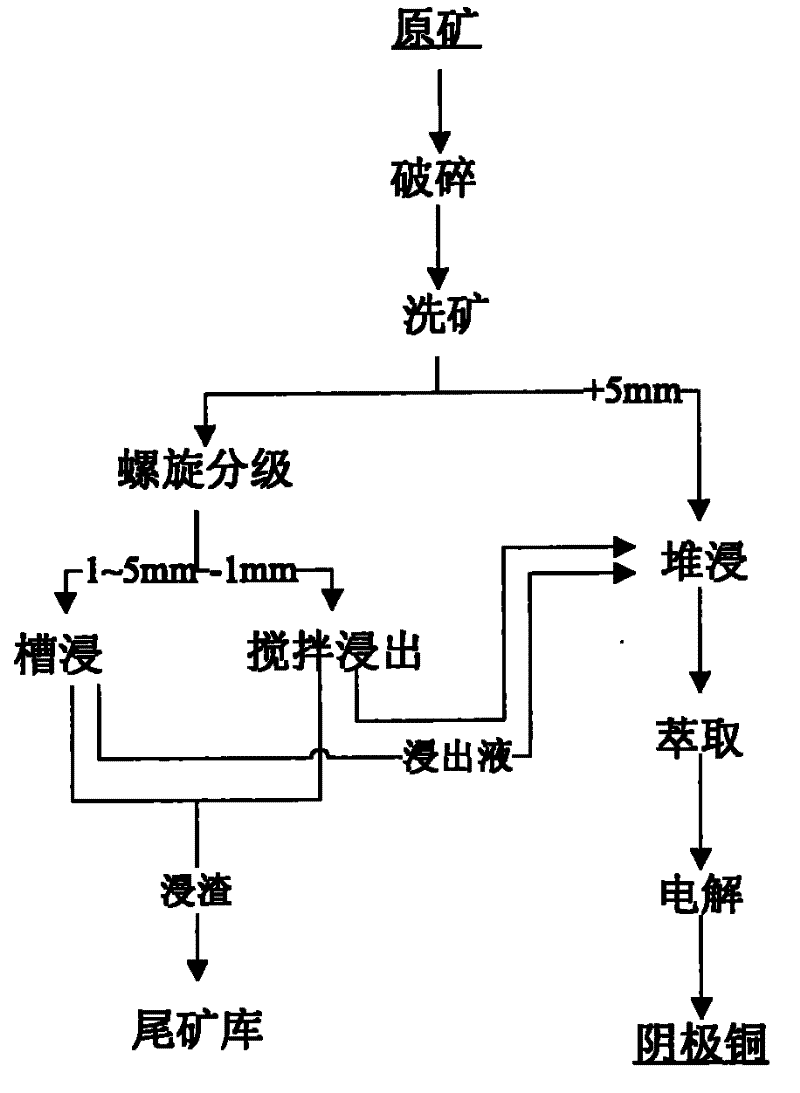

Method of classified leaching of oxidized ore with abundant mud

InactiveCN101857917BImprove permeabilityImprove leaching rateProcess efficiency improvementHigh rateResource utilization

The invention belongs to the technical field of special metal ore mining, and relates to a method of leaching of oxidized copper ore with abundant mud. In the technical scheme of the invention, based on the ore crushing and by means of ore washing as well as spiral classification, the ores are classified according to the particle size, and the different leaching processes are used for the ores with the different particle sizes; the ores can be classified into massive ore, powder ore and shale ore through crushing, water washing and classification, then the classified ores are respectively conveyed to the heap leaching section, the tank leaching section and the mix leaching section via a belt, a loader and a pipeline, and in the ore crushing system, the two-section open circuit or closed circuit way is adopted for rough crushing and fine crushing to crush the ore particles of -500mm raw ore to -30mm; and the massive ores of +5mm are leached by the heap leaching process, the powder oresof 1-5mm are leached by the tank leaching process, and the shale ores of -1mm are conveyed into the mix leaching system for processing. The invention solves the problem of stockyard hardening due to the high mud content of the ore, and the powder ores and the shale ores are fully used. Therefore, the invention has high rate of resource utilization. Moreover, the method solves the problem of difficult processing of the oxidized copper ore with abundant mud.

Owner:XIZHI ELECTRONICS MATERIALS BRANCH YUNNAN COPPER IND GRP +2

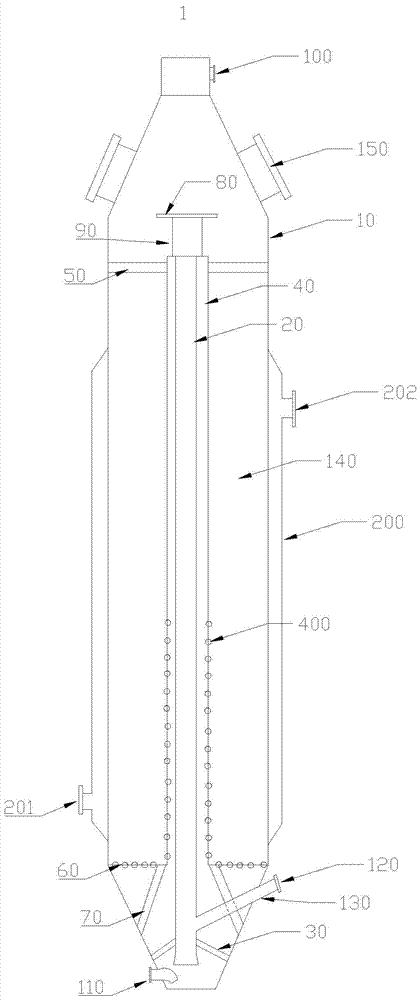

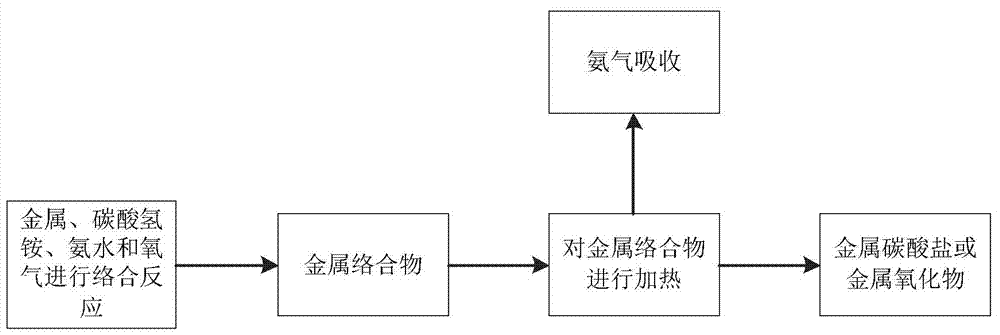

Dissolved metal leaching tank and leaching process for producing metal compounds by ammonia method

ActiveCN106430279BImprove reaction efficiencySave energyCopper oxides/halidesZinc compoundsMetal leachingMetallurgy

The invention discloses a molten metal leaching tank for producing a metallic compound through an ammonia process and a leaching process. The molten metal leaching tank comprises a leaching tank shell, a circulating pipe, an isolating sleeve and a pore plate with an opening; a reaction gas outlet is formed in the top of the leaching tank shell, and a discharging opening is formed in the bottom of the leaching tank shell; the circulating pipe is fixed in the leaching tank shell through a supporting part; the circulating pipe is sleeved with the isolating sleeve, and the isolating sleeve is fixed in the leaching tank shell through a supporting part. The top of space formed between the circulating pipe and the isolating sleeve is closed. The pore plate is fixed in the leaching tank shell through a supporting part, the edge of the pore plate is connected with the inner wall of the leaching tank shell, the lower end of the isolating sleeve is fixed to the pore plate, and the lower end of the circulating pipe stretches to the position below the pore plate through the opening formed in the pore plate. The leaching tank shell is provided with a reaction gas inlet, the reaction gas inlet is correspondingly located below the pore plate and connected with a gas inlet pipeline, and the gas inlet pipeline is communicated with the circulating pipe through an opening formed in the pipe wall of the circulating pipe.

Owner:杜宗鑫

Multifunctional sink

The invention discloses a multifunctional sink. The multifunctional sink comprises a main body, a water channel and a placement box, wherein the water channel is formed in the middle part of the mainbody, the outer edge of the water channel is rotationally connected with the inner wall of the main body, a sealing ring is fixedly arranged at the outer edge of the water channel, a first cleaning slot, a second cleaning slot, a draining slot and a carrying table are formed in the end face of the water channel, an electronic scale is embedded in the end face of the carrying table, draining holesare formed in the bottom end face of the draining slot, a pipe base is fixedly arranged at the middle part of the water channel, a water pipe is fixedly connected above the pipe base, a water valve seat is fixedly arranged above the water pipe, a water outlet is formed in the side wall of the water valve seat, the placement box is fixedly arranged at one side of the water channel, a sieve frame isfixedly arranged at the bottom of an inner cavity of the placement box, and a flow guiding block is fixedly arranged below the sieve frame. The sink used for a kitchen is reasonable in design, easy to use and relatively strong in functions and has broad popularization prospect in modern kitchens.

Owner:重庆牧同电子商务有限公司

Method for reclaiming sodium rhodanate from sodium rhodanate-containing diatomite

InactiveCN101348265AHigh recovery rateThere is no secondary pollution problemThiocyanic acidSodium thiocyanateFixed bed

The invention discloses a method for recovering sodium thiocyanate from diatomaceous earth containing sodium thiocyanate. In the method, the diatomaceous earth containing sodium thiocyanate is mixed with water to form a pulp, and then adopts one or an arbitrary combination of the steps of stirring filtering by a continuous or intermittent stirring vessel, column infiltration, tank leaching and filtering by a belt type filter to separate the obtained pulp, and an aqueous solution of sodium thiocyanate is obtained; the obtained aqueous solution of sodium thiocyanate is subjected to purification by an active carbon fixed bed adsorption method or an active carbon stirring adsorption method, the purified aqueous solution of sodium thiocyanate is a solution with the sodium thiocyanate content of 10 percent, in which the iron ion impurity content is lower than 0.8ppm, and the content of non volatile matters except the sodium thiocyanate is lower than 2.0 percent. and aqueous solution of sodium thiocyanat can be reused in the system, so that the overall recovery of sodium thiocyanate is higher than 95 percent; moreover, the method of the invention is also simple in process and easy in operation.

Owner:ZHEJIANG UNIV

Rotary continuous leaching unit and continuous countercurrent leaching method

ActiveCN104651608BLabor savingReduce power consumptionProcess efficiency improvementHeap leachingMaterials science

The invention discloses a rotary continuous leaching unit and a continuous countercurrent leaching method. According to the method, mineral aggregate is added from one end of a closed tunnel container with stirring function, and is continuously moved to the other end; and a leaching solution is injected from the other end of the tunnel container and is continuously moved in the opposite direction to the movement direction of the mineral aggregate, thereby achieving the goal of continuous countercurrent leaching. The practical equipment is an aggregate unit composed of a rotary leaching chamber, a head thickening machine, a tail thickening machine and a matched system. The method and unit disclosed by the invention are used instead of the traditional technique and equipment based on heap leaching, tank leaching, multistage countercurrent vat leaching or the like, thereby implementing continuous high-efficiency operation, simplifying the equipment configuration, adapting to multiple different grades of mineral aggregate, and achieving the goals of energy and manpower saving and environment friendliness.

Owner:薛平 +1

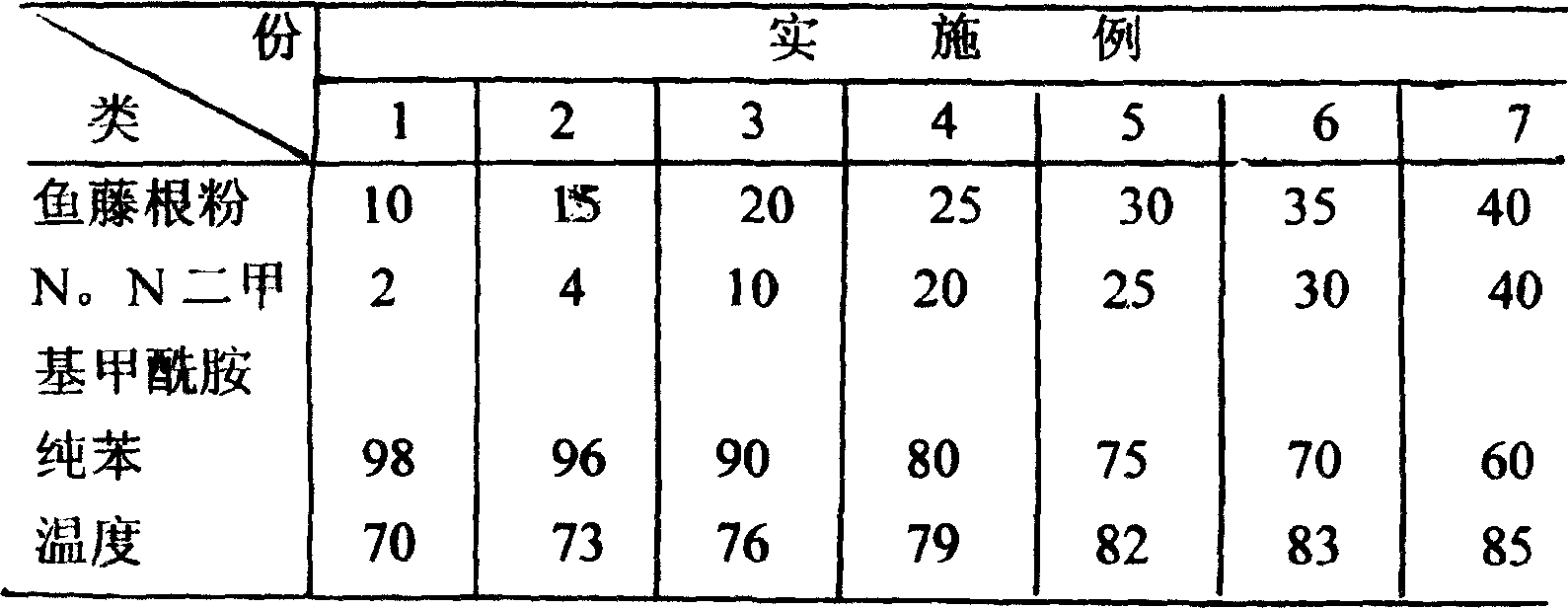

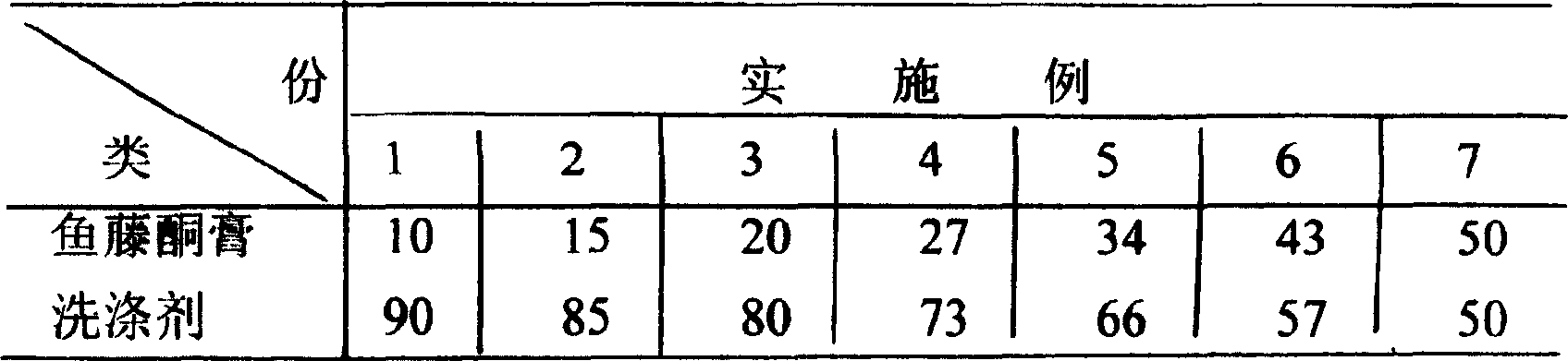

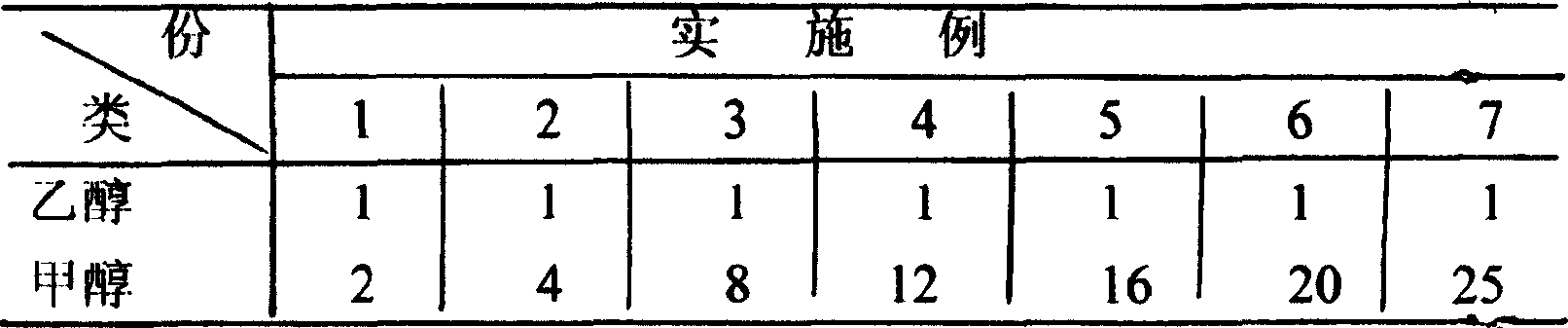

Fast extracting and purifying process for fast barbasco

The present invention relates to a rapid purification and extraction method of rotenone original drug. The main process is to pulverize deertenone root and stir and extract it in an extraction kettle. Pure benzene or trichlorethylene is added to the water-repelling agent N·N-dimethylformamide, after coarse filtration and submicron suction filtration, it is concentrated in a reactor under reduced pressure, and washed in a scrubber. The washing liquid is an alcohol substance. Such as methanol, ethanol mixed liquid, etc.; washing qualified discharge, drying the crystals to obtain the finished product. The invention is characterized by fast extraction speed, high production efficiency, low production cost, less waste of rotenone, high recovery rate, can effectively reduce environmental pollution, and is especially suitable for industrial application.

Owner:郑树芹

Paint spraying and drying method

InactiveCN108855842AReduce use costImprove spraying effectPretreated surfacesMetallic material coating processesMechanical equipmentZinc

A paint spraying and drying method includes following steps: 1, removing oil: removing oil stain on the surface of a black metal workpiece in the process of production through a tank leaching method;2, cleaning; 3, removing rust: adopting acidic rust removal to remove rust on the surface of steel through the tank leaching method; 4, cleaning; 5, treating the surface: treating the surface before phosphorization through the tank leaching method; 6, phosphorizing: using zinc-class phosphorizing liquid to phosphorize the surface of the steel through the tank leaching method; 7, cleaning; 8, drying; 9, spraying. Each link is conducted through the tank leaching method, and ingredients in a formula are proportioned and matched, so that spraying effect is good, and less proneness to shedding is realized; a special drying process is adopted, so that adhesion time is prolonged, and using cost of mechanical equipment is lowered.

Owner:合肥优亨旺信息科技有限公司

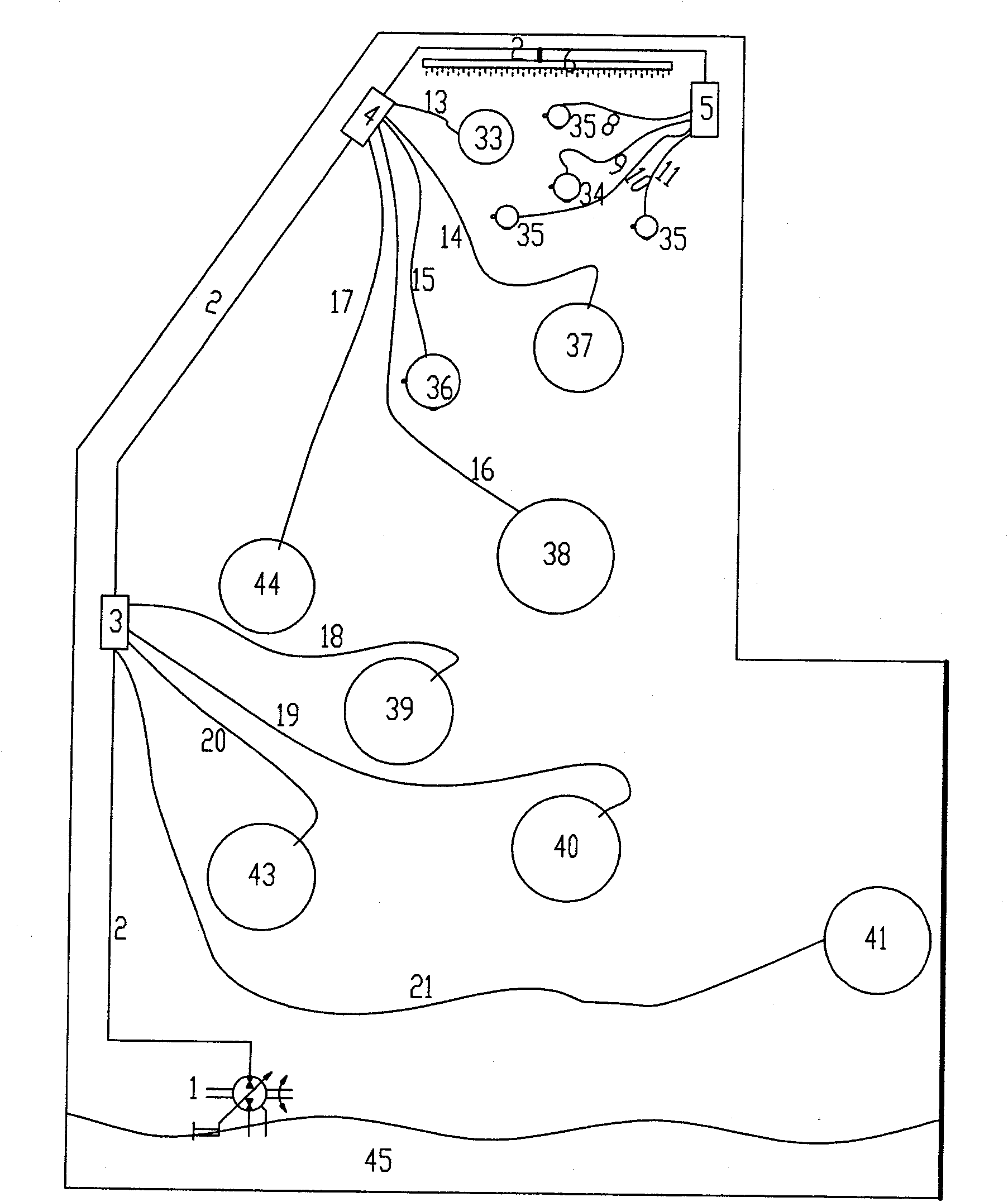

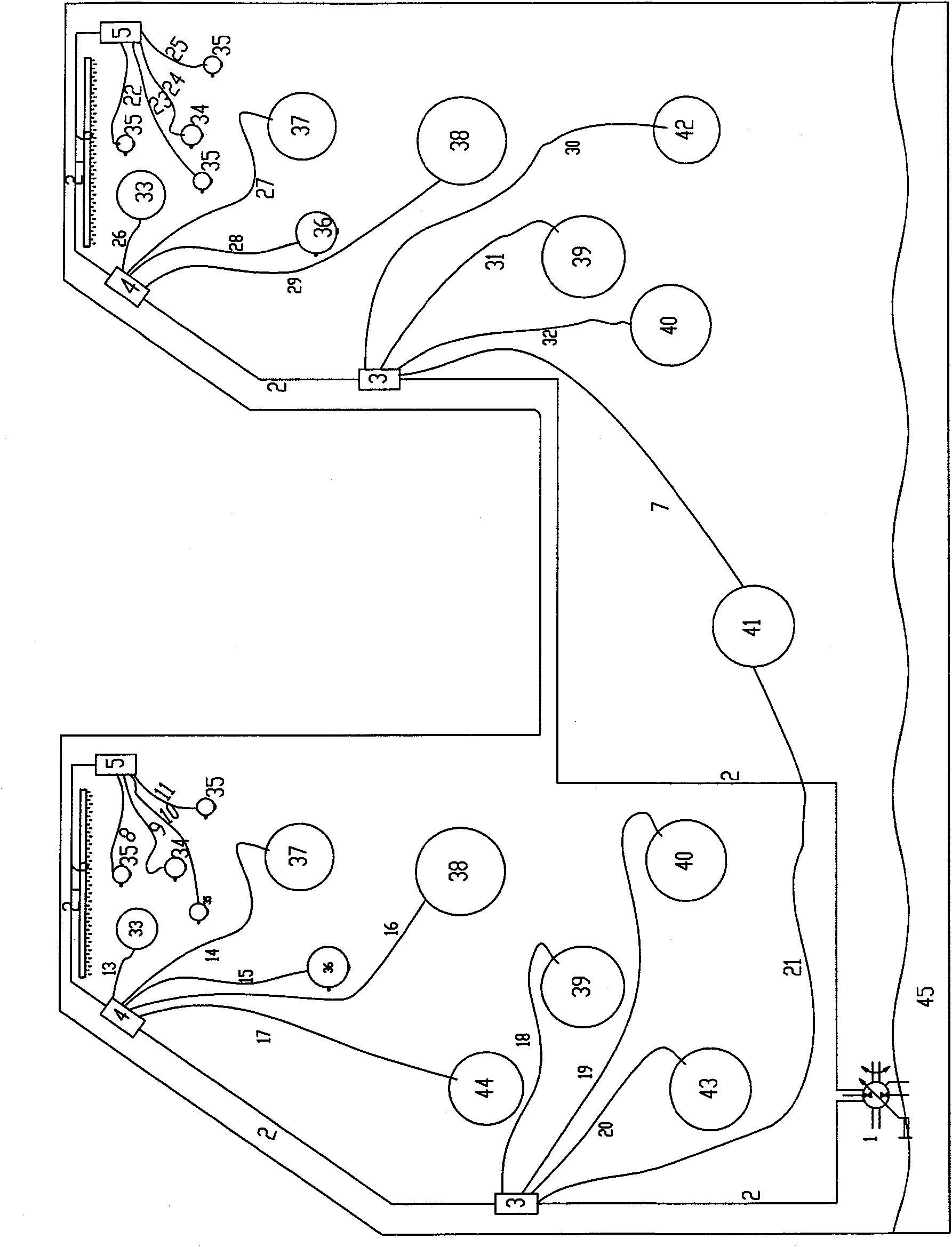

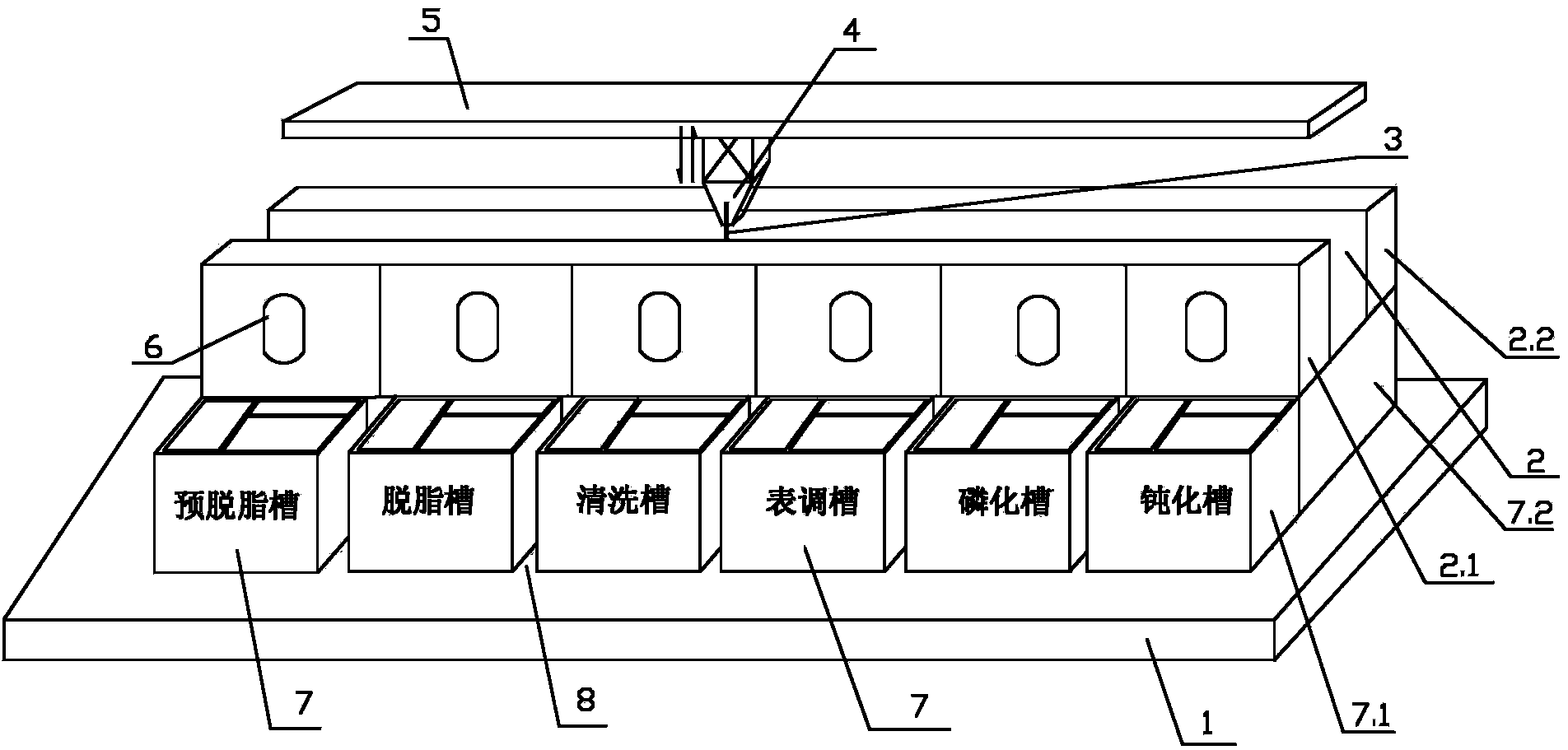

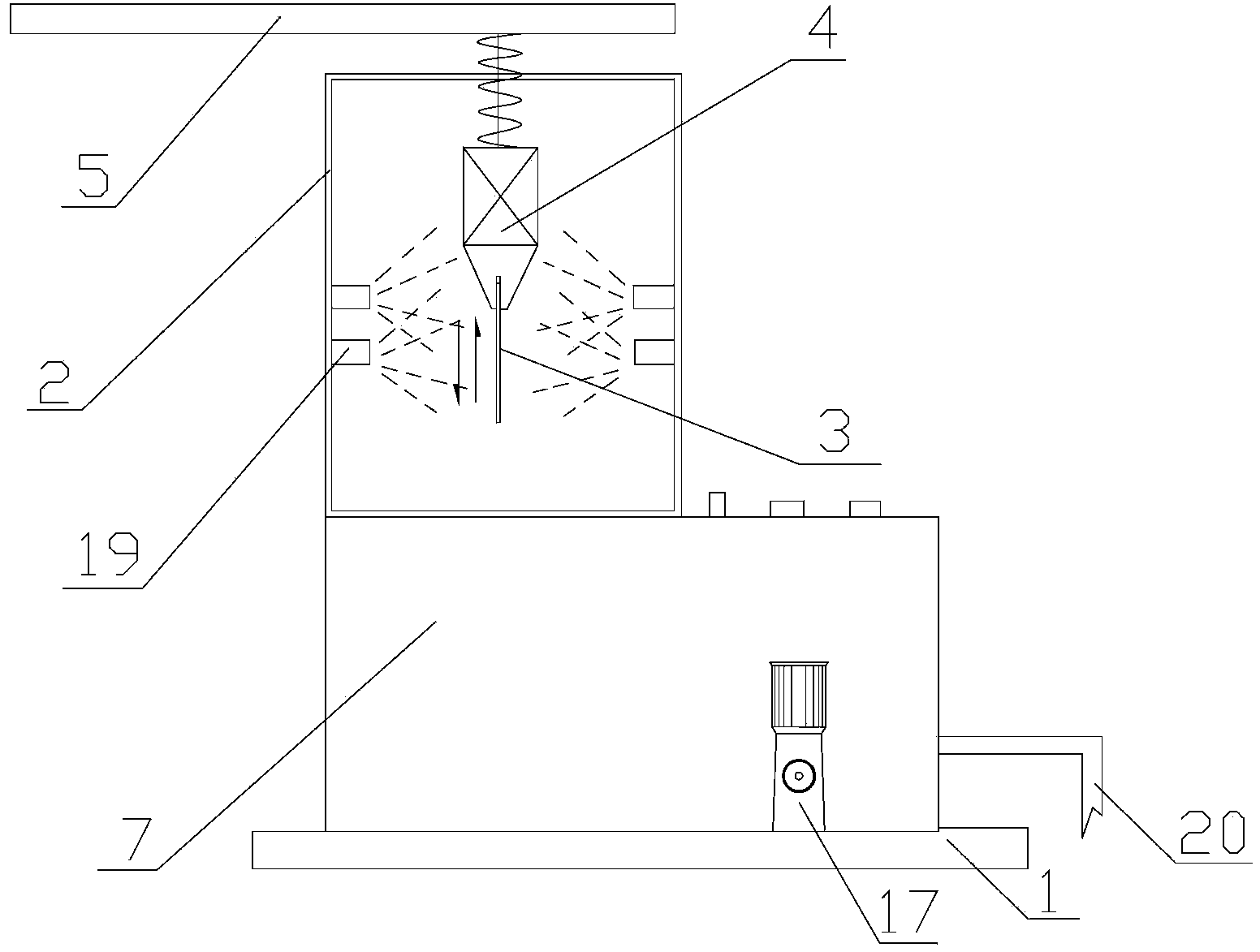

Coating pretreatment analog device with functions of tank leaching and sprinkling

InactiveCN103357560BRealize free switchingReal simulation processPretreated surfacesCoatingsBiochemical engineeringComputer terminal

The invention discloses a coating pretreatment analog device with functions of tank leaching and sprinkling. The coating pretreatment analog device comprises a baseplate and a plurality of processing analog device units arranged on the baseplate, wherein each processing analog device unit comprises a tank body arranged on a base, a hot water tank arranged in the tank body and a stirring pump for stirring liquid medicine in the tank body; each tank body comprises a tank body front part with an end cover and a tank body rear part without an end cover, a division board is arranged on the top surface of each tank body rear part, a nozzle is arranged on the side wall of each division board, and a heating coil for heating a hot water tank is arranged on each tank body. The device can realize tank leaching and sprinkling in the coating pretreatment process, and can realize randomly switching and combination of the two functions so as to realize real analog of the coating pretreatment process; the tank leaching and the sprinkling of a workpiece can be finished under the clamping of a mechanical hand, and the actions are controlled by a computer terminal, without needing manual operation of operators, so that the security of the operators can be ensured.

Owner:武汉钢铁有限公司

A method for harmless treatment of arsenic-containing slag liquid in biological pre-oxidation-cyanidation gold extraction process of arsenic-containing gold concentrate

ActiveCN105567960BImprove stabilityReduced stabilityProcess efficiency improvementCyanideLiquid slag

The invention discloses a harmless treatment method of arsenic-bearing slag liquid of the biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate. The method includes the steps of firstly, pre-oxidizing the arsenic-bearing gold concentrate with a biological tank leaching process to obtain pre-oxidized ore pulp; secondly, performing solid-liquid separation on the pre-oxidized ore pulp to obtain first supernate and first underflow; thirdly, pre-neutralizing the first supernate, and performing solid-liquid separation on the pre-neutralized first supernate to obtain second supernate and second underflow; fourthly, performing goethite iron precipitation and arsenic fixing on the second supernate for 2-4 hours, and then performing solid-liquid separation to obtain overflow liquid and third underflow, allowing the overflow liquid to enter the biological tank leaching process, allowing part of the third underflow serving as seed crystal to return to the reaction device of the iron precipitation and arsenic fixing, and discharging the rest of third underflow; fifthly, performing cyanidation carbon-in-pulp leaching on the first underflow to obtain ore pulp; sixthly, performing ferric salt aeration arsenic fixing on the ore pulp obtained in the fifth step. The method provides necessary technical support for the environment-friendly, efficient and low-cost development of the arsenic-bearing gold concentrate.

Owner:厦门紫金矿冶技术有限公司

Liquid distributing method in tank leaching process

InactiveCN101857916BAvoid gatheringImprove leaching rateProcess efficiency improvementMetalMaterials science

Owner:UNIV OF SCI & TECH BEIJING +2

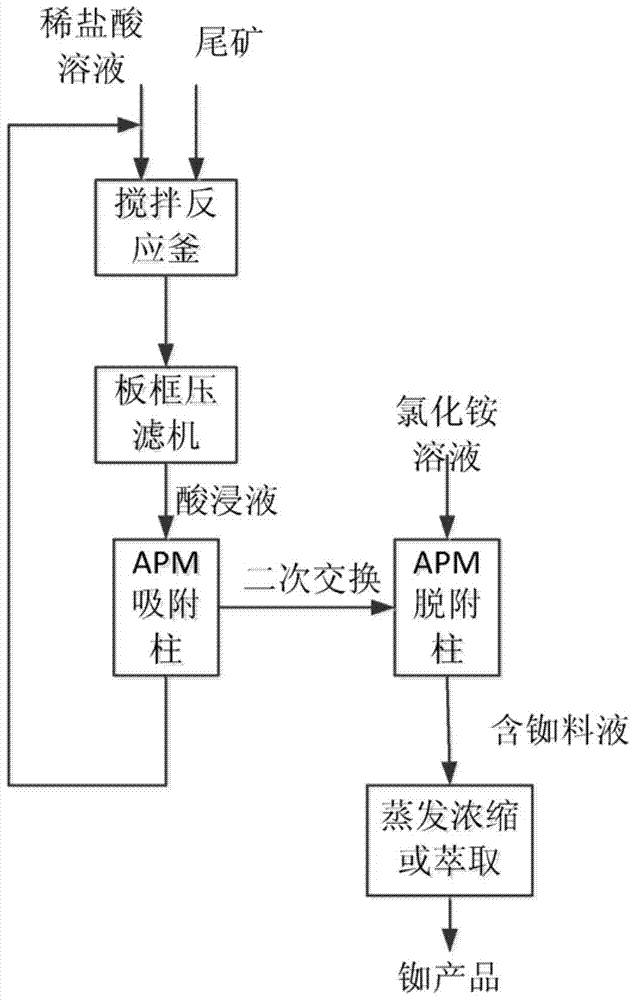

A method for separating and enriching rubidium from tailings containing rubidium

Owner:WUHAN UNIV OF TECH

Metal non-phosphorus pretreatment agent as well as preparation method and treatment method thereof

The invention discloses a metal non-phosphorus pretreatment agent as well as a preparation method and a treatment method thereof. The metal non-phosphorus pretreatment agent is prepared from 0.5 to 1percent of aqueous solution A and 2 to 4 percent of aqueous solution B, wherein the aqueous solution A is prepared from the following components in percentage by mass: 5 to 15 percent of fatty acid salt, 1 to 3 percent of polyethylene glycol, 2 to 4 percent of triethanolamine, 2 to 3 percent of fatty acid monoethanolamide and the balance of deionized water; the aqueous solution B is prepared fromthe following components in percentage by mass: 4 to 6 percent of citric acid, 3 to 5 percent of hydroxylamine hydrochloride, 1 to 2 percent of tartaric acid, 1 to 2 percent of sodium hydroxide, 0.5 to 1 percent of sodium molybdate, 0.1 to 0.4 percent of sodium tungstate and the balance of deionized water. The metal non-phosphorus pretreatment agent disclosed by the invention is free from phosphorus, can be used at normal temperature, can be applied to treatment of tank leaching lines and acid-washing workpieces, and has a good effect.

Owner:德清县康祺化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com