Dissolved metal leaching tank and leaching process for producing metal compounds by ammonia method

A metal compound, leaching tank technology, applied in copper compounds, zinc compounds, inorganic chemistry and other directions, can solve the problems of high energy consumption, a large amount of washing wastewater, troublesome treatment, etc., to achieve the effect of fast speed, improve reaction efficiency and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

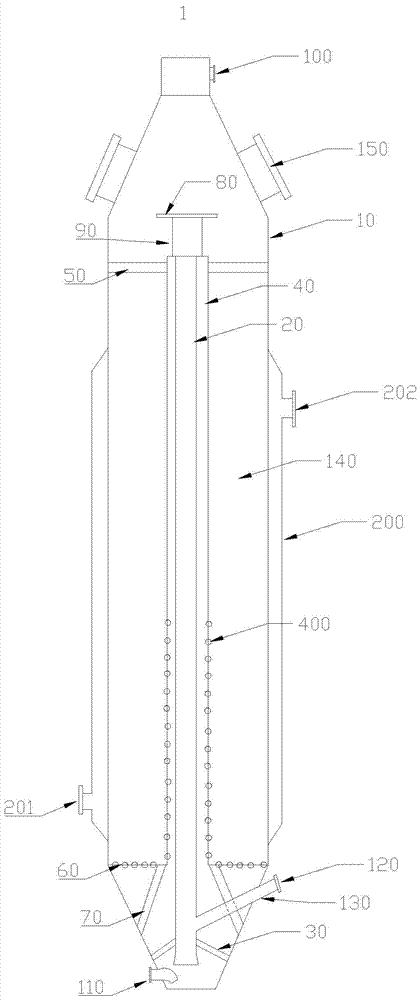

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

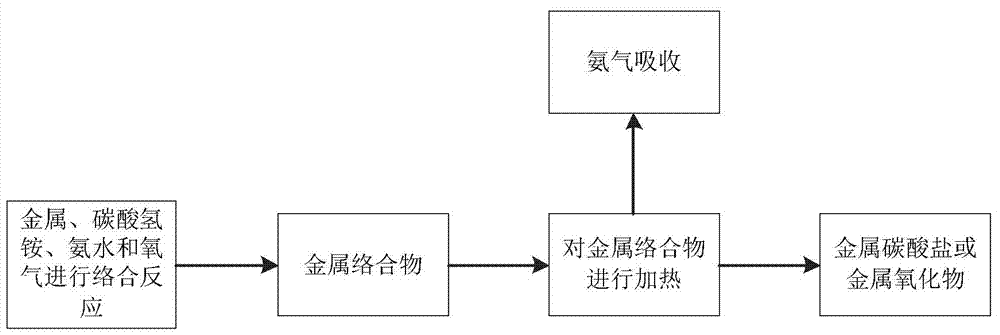

[0031] Such as figure 2 Shown, the principle that the ammonia method that the present invention adopts produces metal compound (comprising copper oxide, copper carbonate, zinc carbonate and nickel carbonate etc.) is: metal (copper, nickel, zinc etc.), ammonium bicarbonate solution (ammonium bicarbonate aqueous solution and Mixed solution of ammonia water) and oxygen for leaching and complexation reaction to form a metal complex, heating the metal complex, depending on the heating temperature, will generate ammonia and metal oxides (or metal carbonates), etc. .

[0032] Taking the preparation of active copper oxide as an example, it includes the following steps:

[0033] (1) Lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com