A method for separating and enriching rubidium from tailings containing rubidium

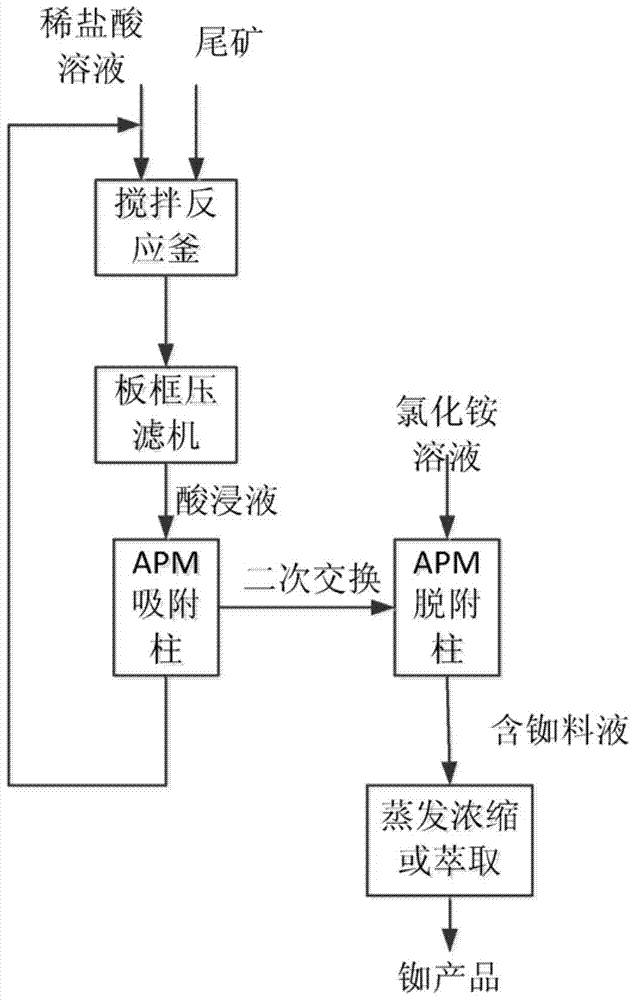

A technology for separation and enrichment and tailings, which is applied in the field of separation and enrichment of rubidium and potassium feldspar decomposition tailings leaching solution, can solve the difficulty of increasing the complexity of the purification process, separation, purification and product deep processing and other issues, to achieve the effect of reducing operating costs, simplifying production equipment and operation, and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of silica-loaded ammonium phosphomolybdate adsorbent: Weigh 5g of ammonium molybdate and dissolve it in 100mL of deionized water, stir and dissolve, slowly add 0.25mL of phosphoric acid with a mass concentration of 85%, heat to 80°C, and stir Add about 2mL of concentrated nitric acid with a mass concentration of 68% dropwise under conditions until the pH of the solution is 1. After a large amount of yellow precipitates are formed, add 18g of activated macroporous silica gel, stir for 1.5h, leave to stand for 10h and then filter with suction. Dry under vacuum at 80 °C for 6 h. The obtained solid was calcined in a muffle furnace at 200 °C for 4 h to obtain AMP-SiO 2 .

[0026] Take 200g of potassium feldspar decomposition tailings, add 500mL of 0.1mol / L dilute hydrochloric acid solution, leaching with ultrasonic vibration for 1.5h, filter and dilute to 1000mL to obtain acid leaching solution. Take AMP-SiO 2 10g is packed in an adsorption column with a heigh...

Embodiment 2

[0028] The process flow is basically the same as in Example 1, except that the adsorbent used is aluminum oxide-loaded ammonium phosphomolybdate. The adsorption rate and resolution rate were 62% and 97.5%, respectively.

[0029] The preparation process of the adsorbent is as follows: take 6.0 g of molybdenum trioxide and add it into a 150 mL Erlenmeyer flask, stir and dissolve until it becomes a milky white suspension. Heating to 115°C under magnetic stirring, the reactant reached boiling, during the heating process, 3mL of concentrated phosphoric acid was added dropwise to the Erlenmeyer flask, and the reactant gradually changed from milky white to golden yellow. Continue to heat and stir, and when the reactant turns from golden yellow to green, use 85% H 3 PO 4 Adjust the acidity and alkalinity of the solution to about pH=10, and keep the slight boiling reaction for 2.5h. Maintain liquid level. Cool to room temperature after completion of the reaction, and dropwise add m...

Embodiment 3

[0031] The process flow is basically the same as in Example 1, except that the adsorbent used is ammonium phosphomolybdate supported on titanium aluminum pyrophosphate. The adsorption rate and resolution rate were 60.9% and 96.3%, respectively.

[0032] The preparation method of the adsorbent is as follows: under the condition of 15°C, weigh 6.72g of ammonium molybdate and dissolve it in 40mL of water. Measure 5 mL of concentrated nitric acid with a mass concentration of 68% and add it to 35 mL of water. After cooling to normal temperature, add 2 g of potassium pyrophosphate to it and mix well. This solution was slowly and uniformly added dropwise to the ammonium molybdate solution within 13.3 hours. After the crystal nuclei appear, quickly sample and filter at a certain interval, and measure the volume of the solution at the same time until the pH value of the solution drops to 1. Measure 30mL of concentrated sulfuric acid in a beaker, place it in an oil bath, start heating,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com