Surface tank leaching process for classified heap building

A tank leaching and surface technology, applied in the direction of improving process efficiency, etc., can solve the problems of low leaching rate of ore heap, uneven solution distribution, high mud content of ore, etc., achieve broad development space, simple process, and improve permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

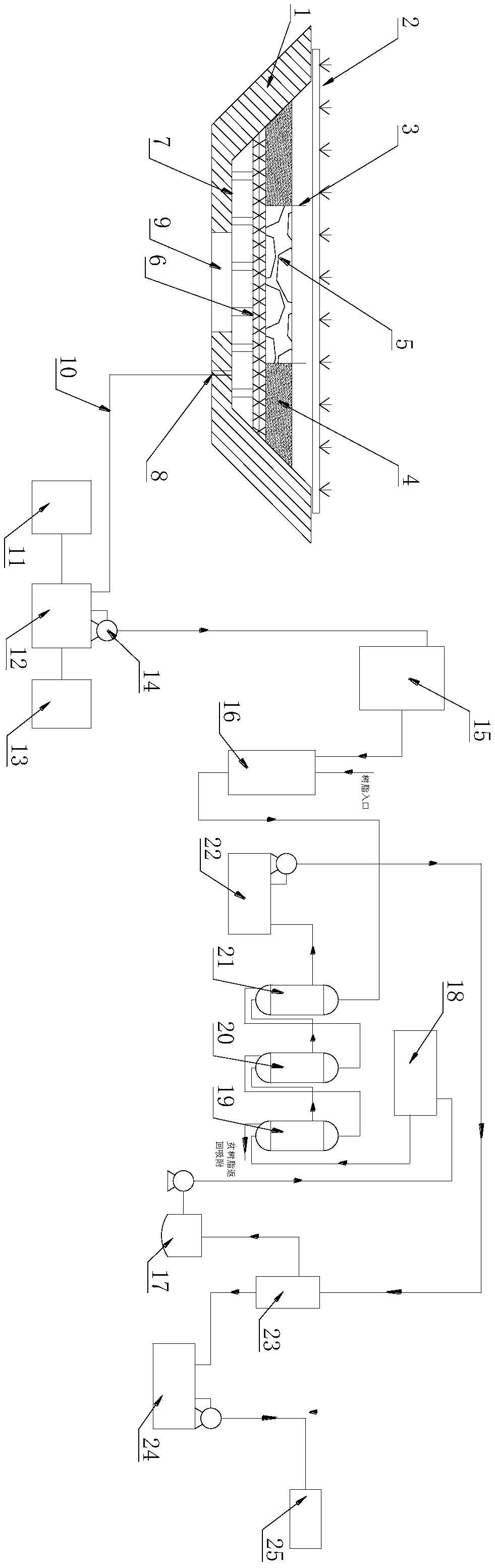

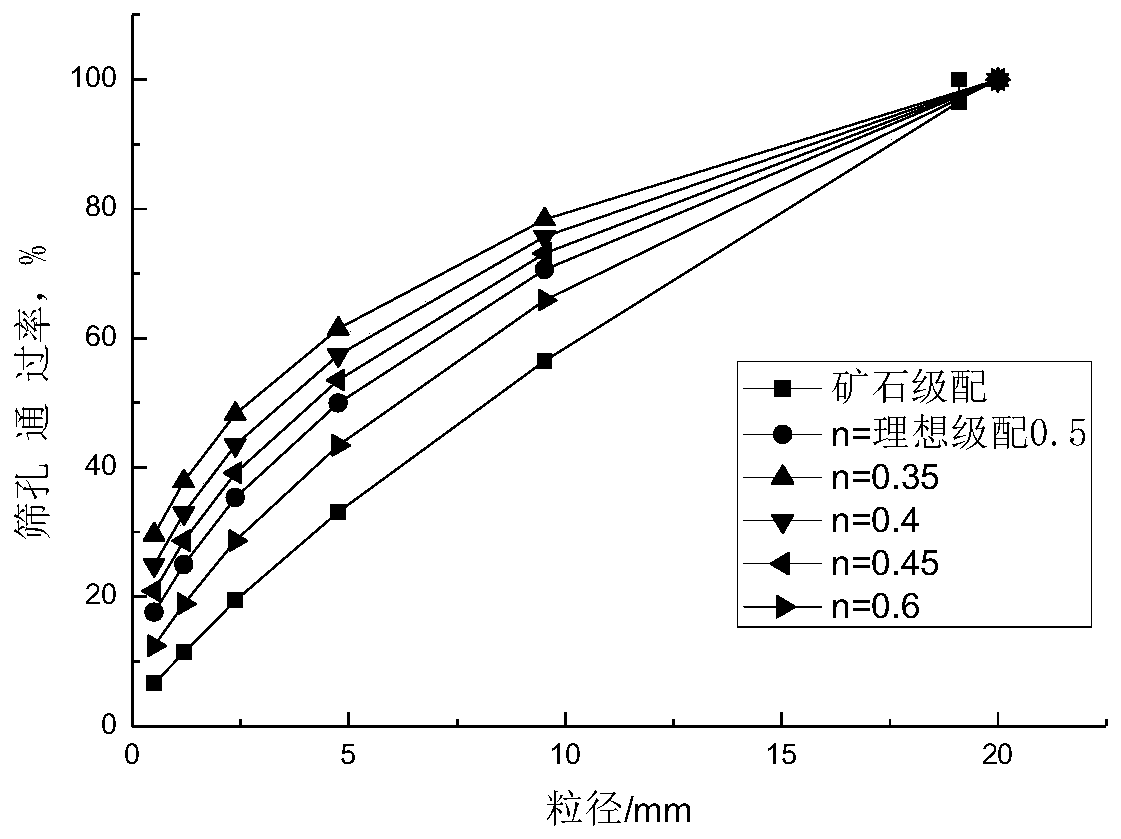

[0025] see figure 1 A surface tank leaching process of classification and heaping. First, the ore is crushed into different particle sizes with a crusher, and then grading is carried out after screening-mixing, and then the ore of different particle sizes is transported to the designated site by an excavator. The belt conveyor transports the crushed ore into a certain particle size to the leaching tank 1 of the surface tank leaching liquid reaction device for classification and heaping, and carries out heap leaching in partitions, and the metal mesh 3 is used between the ore blocks of different sizes Separated; then pump the leaching solution in the liquid distribution tank to the leaching tank 1 for spraying through the liquid supply pump, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com