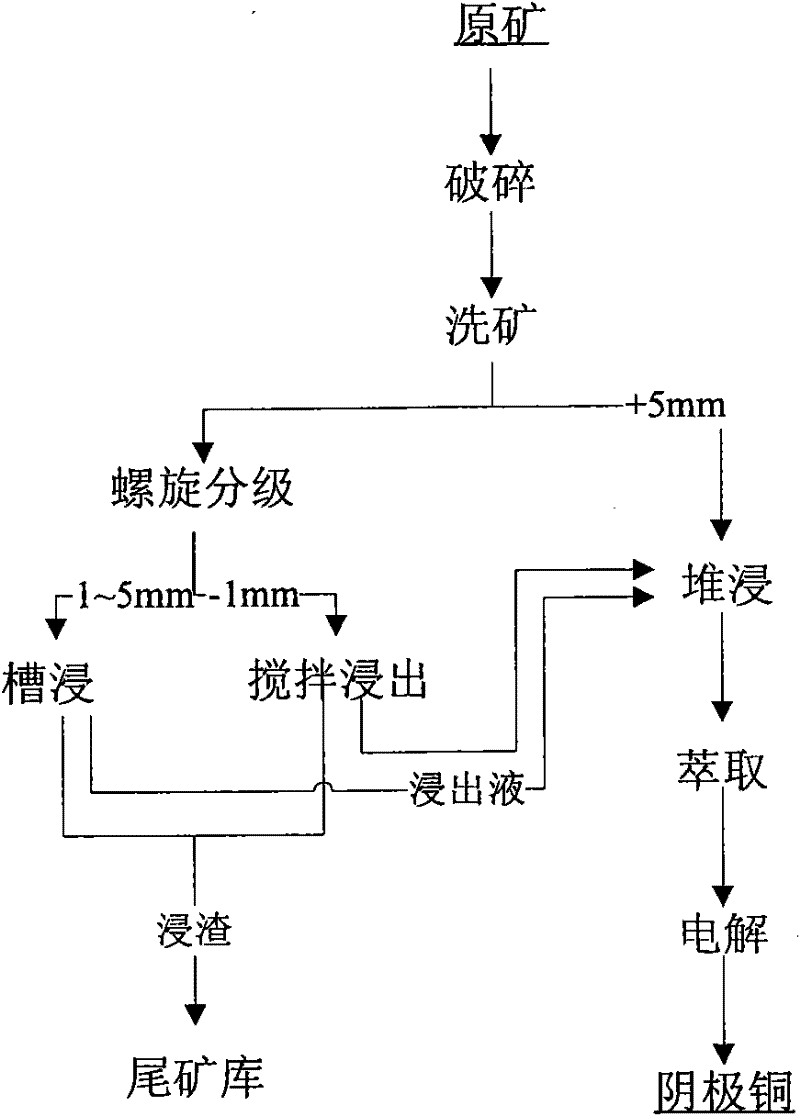

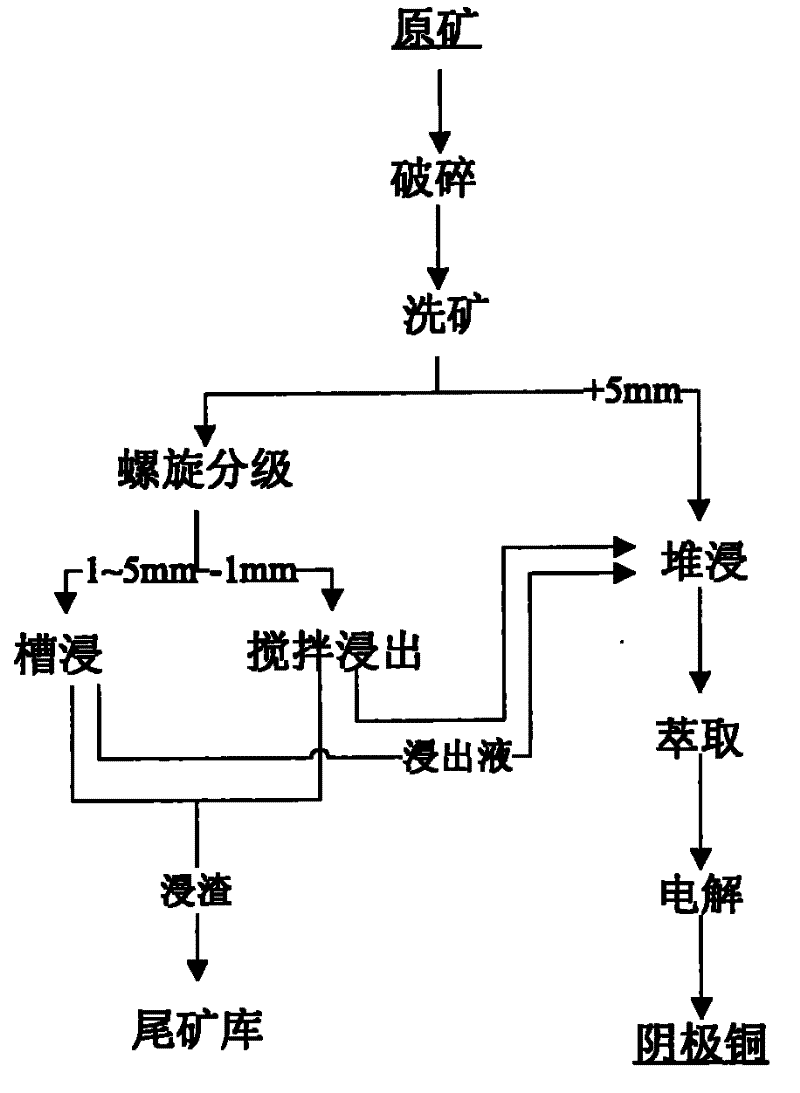

Method of classified leaching of oxidized ore with abundant mud

A technology for high-slime and oxidized copper ore, which is applied in the leaching of copper oxide ores and the field of solution leaching and mining of oxidized ores, can solve the problems of poor leaching effect of high-slime oxidized ores, reduce average acid consumption and achieve high leaching rate , the effect of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This process has been applied in a copper mine in Yunnan. The oxidized ore on the surface of the mine adopts the open-pit mining method, and the ore is severely weathered and very soft. The ore oxidation rate is about 65%, of which the binding rate is 10%, the primary copper sulfide reaches 22%, and the average grade is 1.18%. Due to the strong weathering of the ore, the -1mm ore accounts for about 35%, and the clay minerals such as sericite and kaolin in the ore account for 25%, and the ore contains a large amount of mud. Heap leaching was used for trial production. Due to poor permeability, the infiltration depth of the solution was only 20-30 cm. 100,000 tons of ore was backlogged in the stockyard, and only more than 10 tons of copper were produced.

[0022] (1) Ore crushing

[0023] The raw ore enters the jaw crusher for coarse crushing, and then goes through the cone crusher for fine crushing. The crushed material is -30mm, and then enters the washing and gradin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com