Method for crushing high mud content adhesive material

A crushing method and high mud content technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as clogging and material crushing, achieve environmental pollution problems, good flushing effect, and solve material clogging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] This embodiment takes the crushing of the Moweitang laterite nickel mine in Myanmar as an example. Because Myanmar is located in Southeast Asia, it has a tropical climate and abundant rainfall throughout the year. A large part of the Myanmar nickel mine is in the form of nickel oxide, so it is muddy. Ore with a large amount and water content (especially in rainy season). The ore with high mud content contains 50% water, 13% ore, and 37% argillaceous minerals.

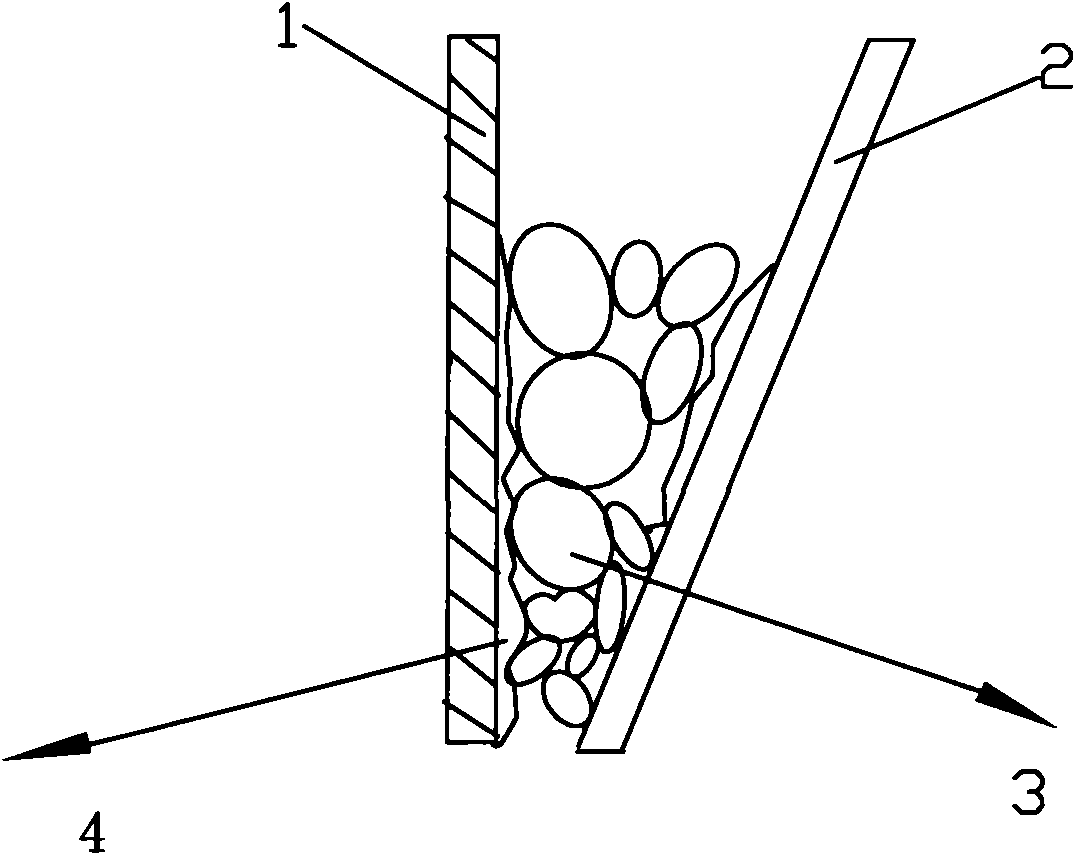

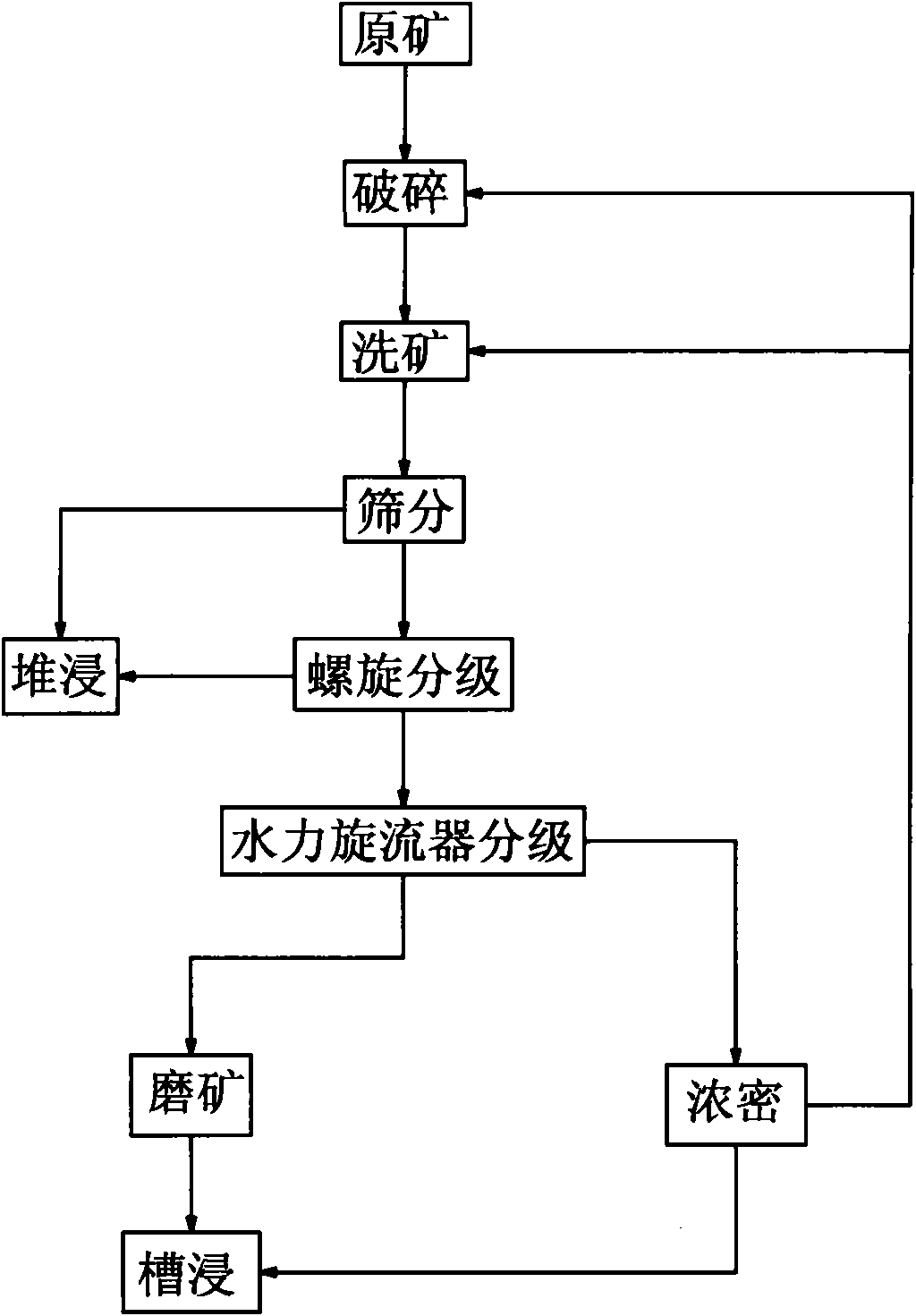

[0044] Please check image 3 , A method for crushing materials with high mud content, the method includes:

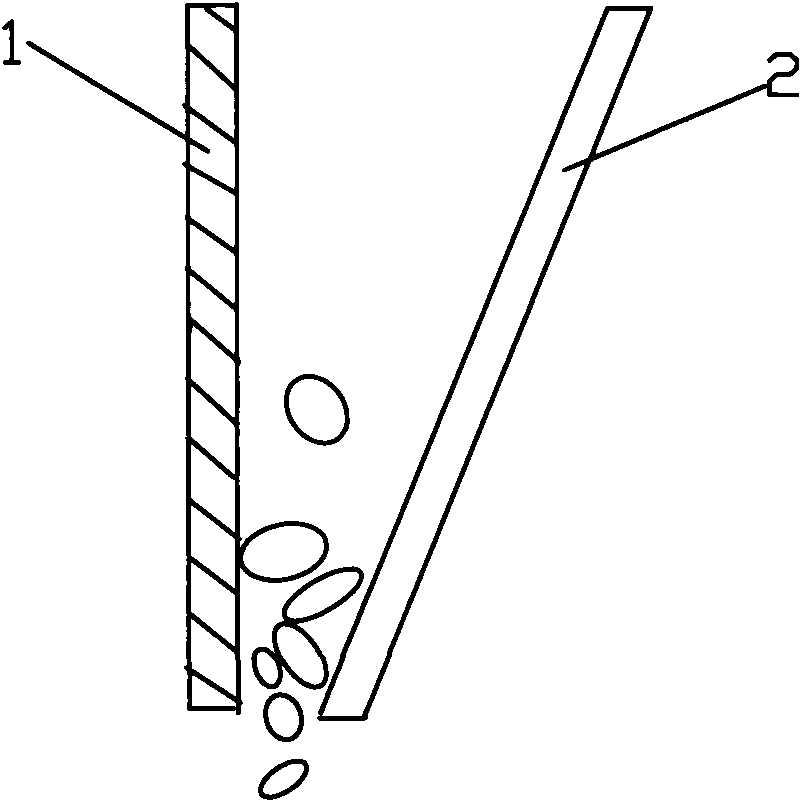

[0045] Step 1. Crushing: crushing the raw ore containing mud and viscous materials, and washing with washing fluid at the same time; wherein, the size of the ore after crushing is less than 20mm;

[0046] Step 2. Washing: Wash the crushed minerals with washing liquid;

[0047] Step 3. It includes:

[0048] Step 31, sieving and grading to divide into coarse particles on the sieve (with a particle size of 5-20 mm) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com