Coating pretreatment analog device with functions of tank leaching and sprinkling

A simulation device and pre-treatment technology, which is applied to the device for coating liquid on the surface, pre-treatment surface, coating, etc., can solve the problems of human skin damage, high labor intensity, and inability to simulate spraying, etc., to achieve convenient computer control , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

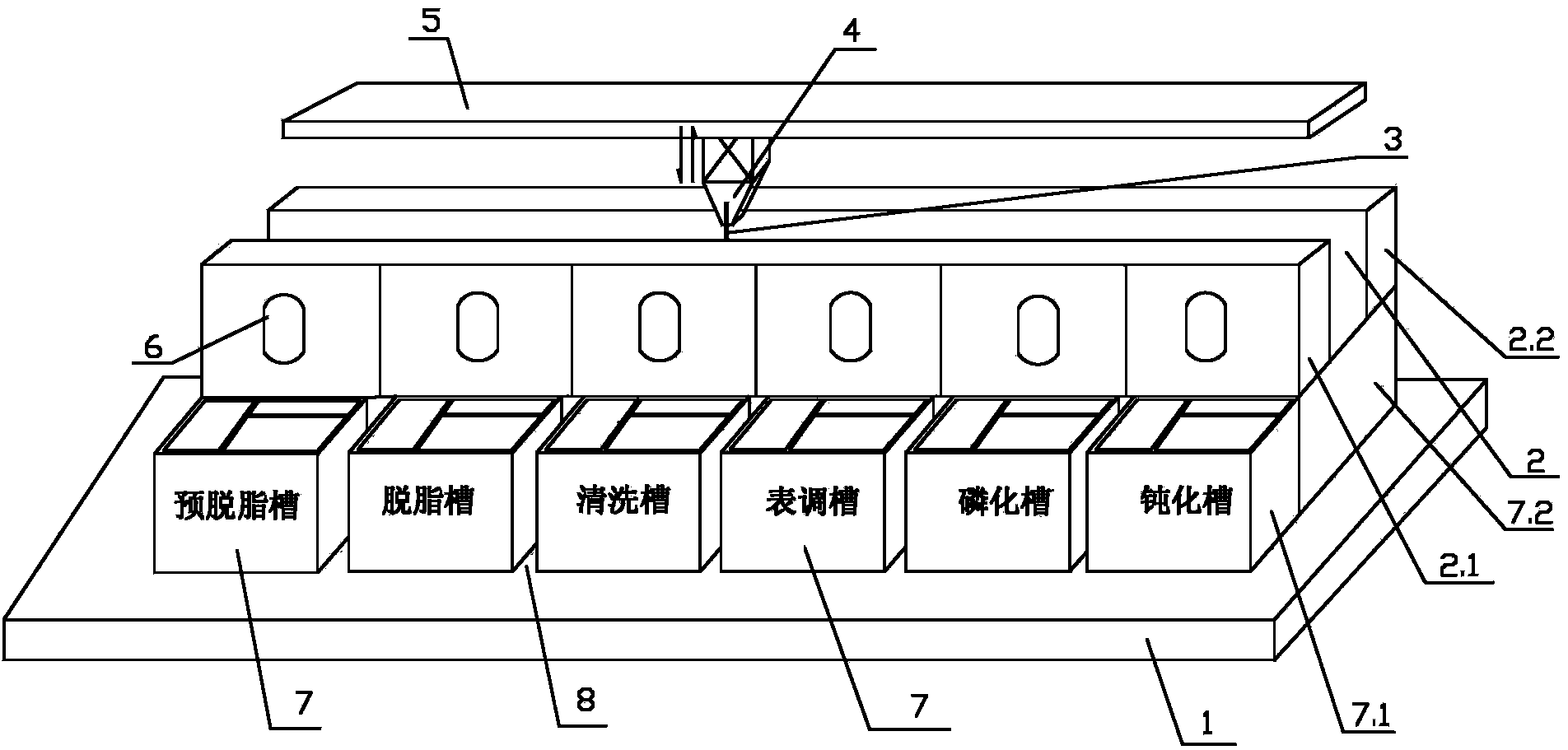

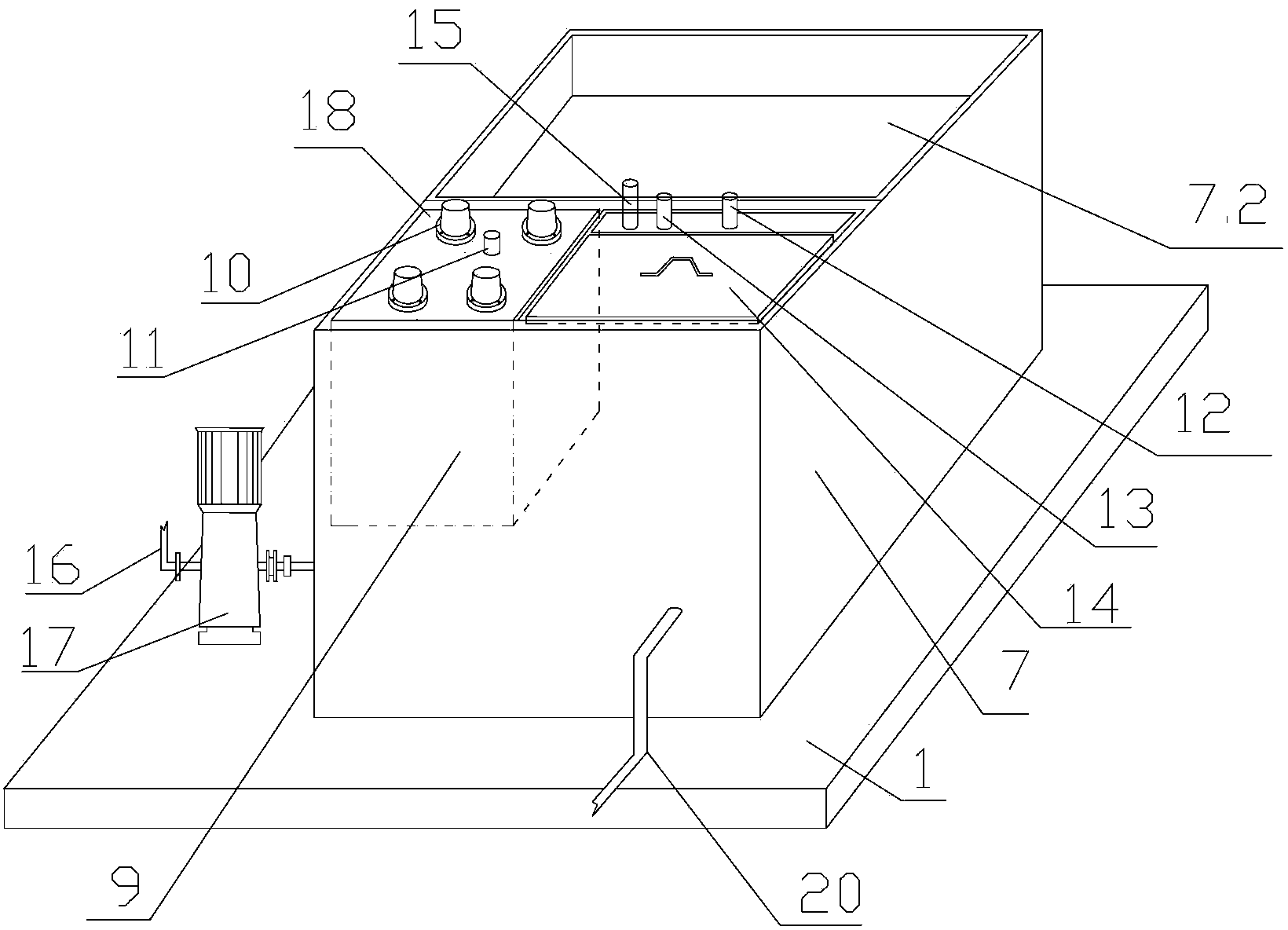

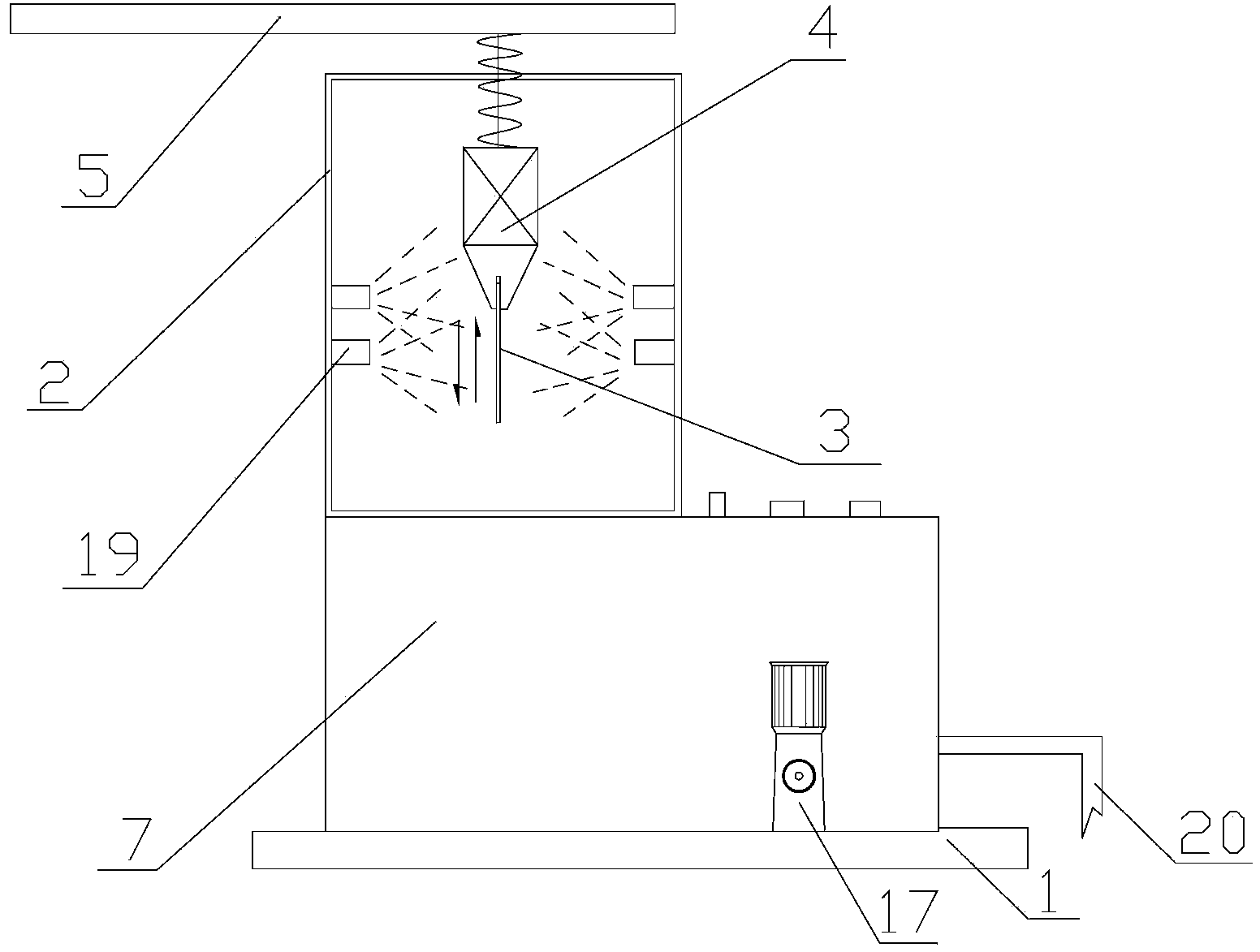

[0024] Such as figure 1 The shown pre-painting treatment simulation device with tank immersion and spraying functions includes a bottom plate 1 and a plurality of processing simulation device units installed on the bottom plate 1 . In this embodiment, six processing simulation device units are arranged on the bottom plate, each processing simulation device unit includes a tank body 7 fixedly installed on the base 1, and the tank body 7 between adjacent processing simulation device units is provided with a gap 8. It is convenient for disassembly and maintenance. The six treatment simulator units correspond to the six main processes of pre-painting treatment: pre-degreasing, degreasing, cleaning, surface conditioning, phosphating and passivation. Each process simulates two processes of tank immersion and spraying.

[0025] combine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com