Liquid distributing method in tank leaching process

A technology of liquid distribution and tank leaching, which is applied in the field of liquid distribution in the tank dipping process and infiltration tank leaching, can solve the problems of low leaching rate, easy clogging screen structure, long leaching cycle, etc., and achieves convenient management and easy promotion. Easy to apply and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

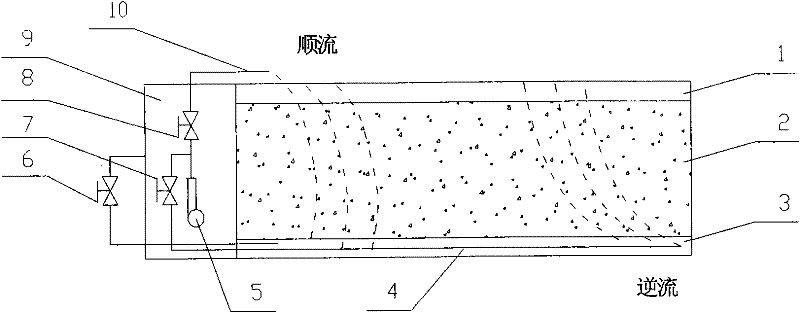

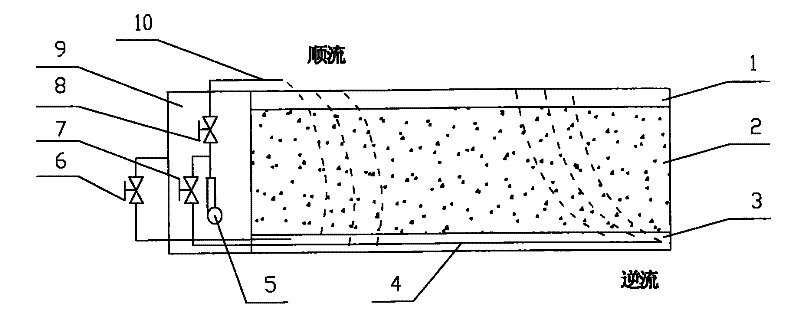

[0014] Below by example in conjunction with accompanying drawing the present invention is further described.

[0015] A copper oxide ore is extracted by acid leaching process, the ore oxidation rate is about 65%, and the ore with a particle size between 1 and 5mm is leached by tank leaching process. During the leaching process, the initial acidity is 50g / L, the thickness of the sand layer is 500-900mm, the liquid-solid ratio is 3:1, and the ore loading in a single tank is between 60-100t.

[0016] The tank leaching facility is composed of six groups of 12 tanks. The bottom (3) of the tank (2) has a false bottom structure. The top of the tank (2) is provided with an overflow port, and the height of the ore layer must not exceed the height of the overflow port. .

[0017] In the initial stage of tank immersion, liquid is distributed in a downstream manner, and only the second plastic pipe (10), the first ball valve (6) and the acid-resistant pump (5) are installed. Start the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com