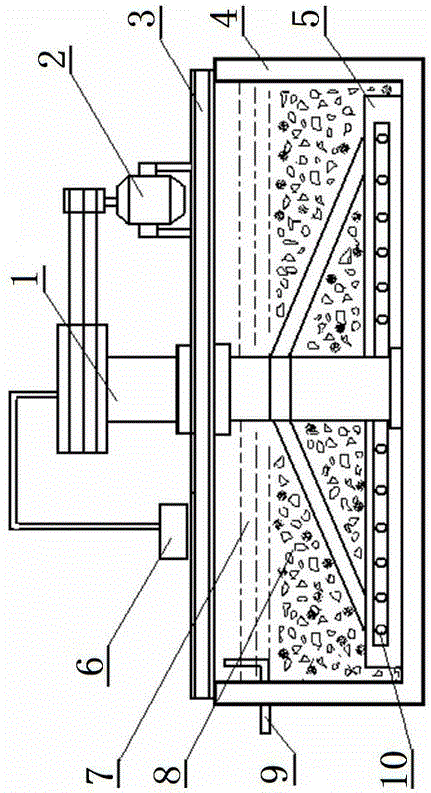

Fast tank leaching test apparatus and application method thereof

A test device and pool immersion technology, which is applied in the field of rapid pool immersion test devices, can solve problems such as work delays, and achieve the effects of accelerating dissolution speed, quick and convenient adjustment, and convenient and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. First, power on the equipment, adjust the stirring device and the inflation device, and make sure that the equipment is in good working condition;

[0035] Step 2. With the stirring device and the aeration device closed, slowly add the mineral material to be leached, keep the particle size of the mineral material less than 20mm, and keep the adding height of the mineral material below the L-shaped rotatable drain pipe 9;

[0036] Step 3: After the mineral material is added, rotate the mouth of the L-shaped rotatable drain pipe 9 in the pool to the vertical upward position, and then start adding the sodium cyanide leaching solution prepared in advance. The amount of the leaching solution should be The ore is completely submerged, but no more than the upper port of the L-type rotatable drain pipe 9;

[0037] Step 4: After the ore 8 is fully infiltrated by the leaching solution, the stirring and aeration can be started, and the speed and aeration volume can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com