Middle thermophilic bacteria and chemical and biological combined heap leaching technique for low-grade primary copper ore

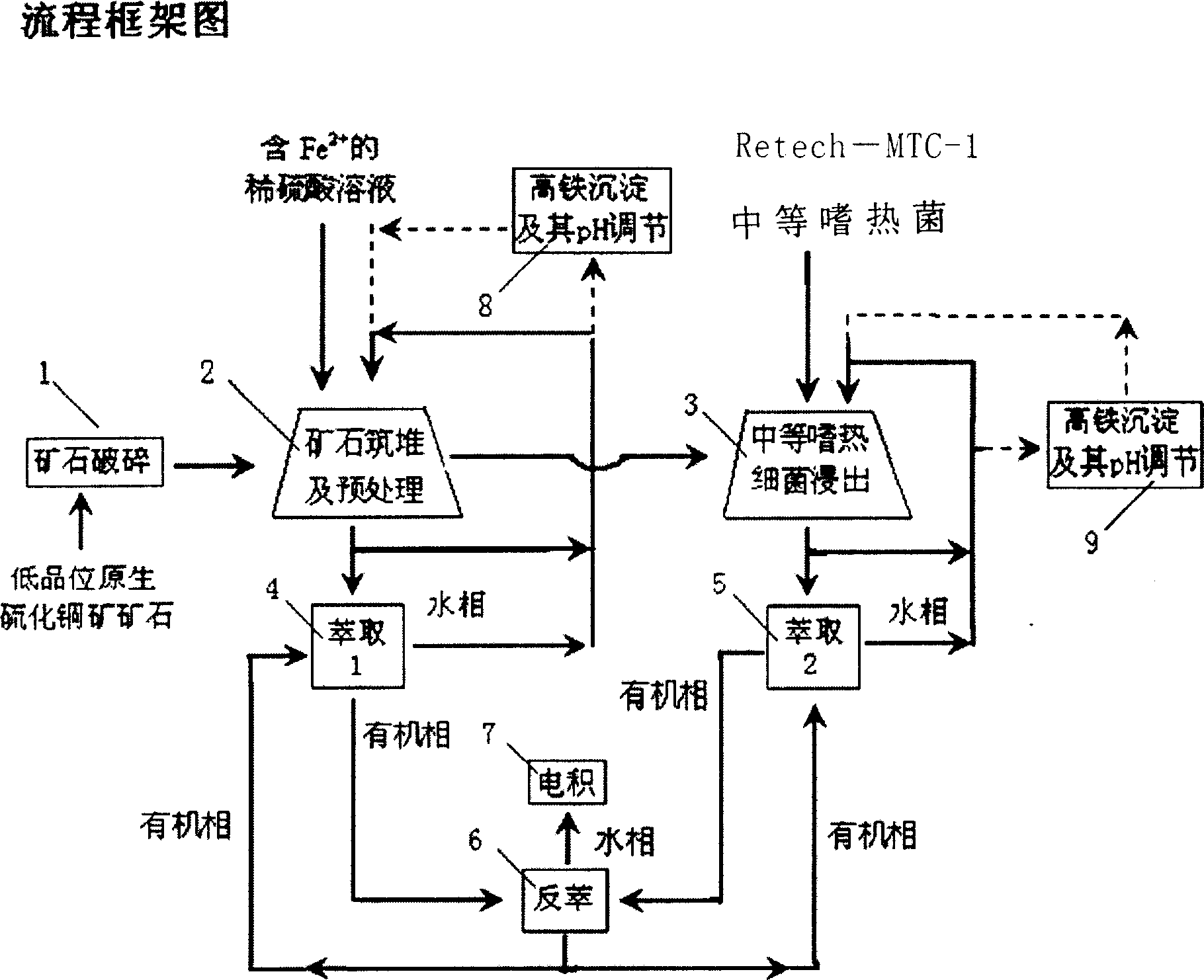

A technology for copper sulfide ore and thermophilic bacteria is applied in the field of combined chemical and biological heap leaching process, which can solve the problems of high cost, complex treatment process and heavy environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Breeding of medium thermophilic bacteria (Sulfobacillus thermosulfidooxidans Retech-MTC-1): the acidic mine water containing medium thermophilic bacteria was collected from the Mojiang mining area, and the above mine water was added to the improved Norrison basic culture medium for breeding. Then carry out leaching and domestication. The inorganic salt composition of the improved basal culture solution is: (NH 4 ) 2 SO 4 0.5g / L, KCl 0.1g / L, K 2 HPO 4 0.2g / L, MgSO 4 ·7H 2 O0.5g / L, Ca(NO 3 ) 2 0.01g / L, yeast extract 0.02%; energy matrix: elemental S. The domestication of bacteria is to add low-grade primary copper sulfide ore powder with a particle size of less than 0.076mm to the tap water containing the above-mentioned nutrients. The concentration of the slurry formed after adding the ore powder is 1-20% by weight, and the pH value is between 1.5-2.5. between; the oxidation-reduction potential of the domesticated bacterial solution is 350-450mV (SCE), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com