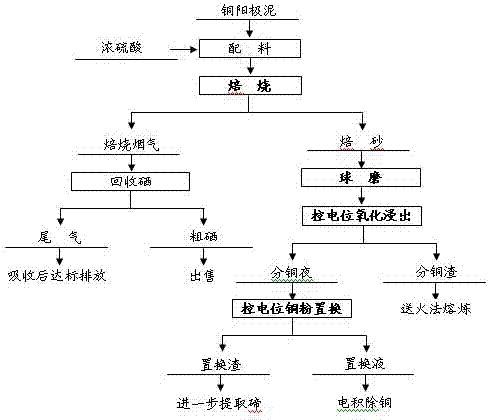

Method for potential-controlled separation and enrichment of tellurium in copper anode slime

A copper anode slime and potential technology, applied in the field of hydrometallurgy process, can solve the problems of reduced silver direct yield, prolonged refining time and high cost, and achieve the effects of reducing reagent consumption, stable technical indicators and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The main components of copper anode slime are (%): Cu11.61, Ni1.53, Sb6.43, Pb19.36, As5.40, Se4.03, Te2.04, Ag3.23 and Au0. 12. Sulfuric acid, hydrochloric acid and hydrogen peroxide are all industrial-grade reagents, and the mass percentage concentrations of sulfuric acid, hydrochloric acid and hydrogen peroxide are 98.1%, 37.2% and 31.0% respectively; the mass percentage of copper in electrolytic copper powder is 99.8%, and the particle size is - 300 mesh and bulk density 2.2g / cm 3 .

[0034] Mix 1500Kg copper anode slime with concentrated sulfuric acid at a mass ratio of 1:0.6, keep the stirring speed at 20r / min for slurry reaction for 4.0h, then add the mixed slurry to the rotary kiln at 0.3t / h for roasting, the temperature in the rotary kiln According to the control of three intervals, the temperature at the feed end is 300°C, the intermediate temperature is 610°C, and the temperature at the discharge end is 680°C, so as to ensure that the reaction time of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com