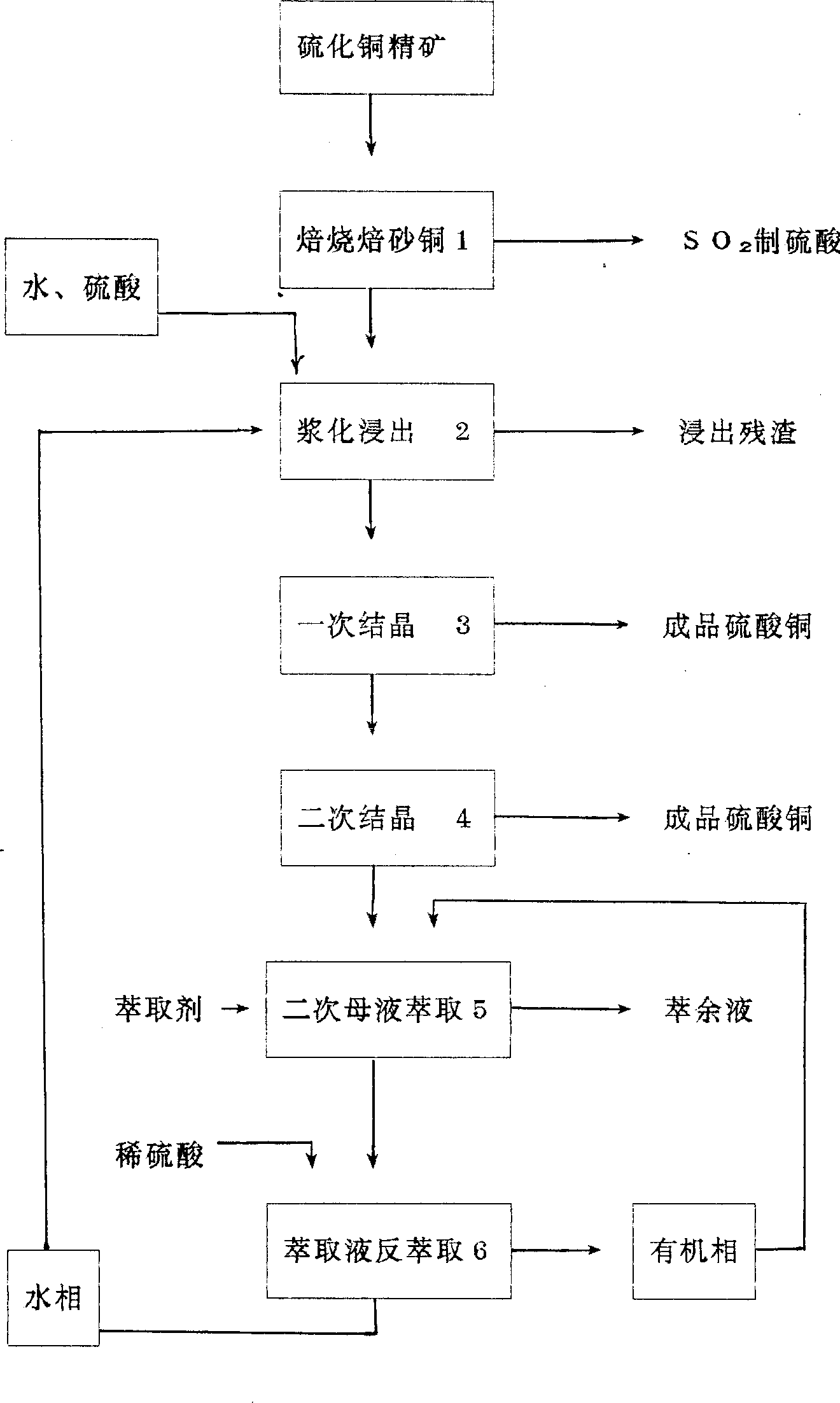

Production process of copper sulfate from copper sulfide ore

A production process, a technology for copper sulfide ore, applied in the direction of copper sulfate, process efficiency improvement, etc., can solve the problems of difficult product purity affecting the copper sulfate production process, increase equipment and production costs, and reduce the total yield of copper sulfate, etc., To achieve the effect of shortening the roasting residence time, reducing the production cost and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0028] Example 4: Take 1000g of calcine containing 19.80% copper, control the liquid-to-solid ratio to 1.2:1, leaching at 80-90℃ for 60 minutes with stirring, the final acid concentration is controlled below 20g / L, and the copper leaching rate is 98.10% 778 g of copper sulfate crystals were precipitated from the leachate, and the recovery rate was 96.07%.

Embodiment 5

[0029] In Example 5, 1000 g of calcine containing 23.78% copper was taken, the liquid-solid ratio was controlled to 1.5:1, and the leaching was stirred at 80-90°C for 60 minutes, the final acid concentration was controlled below 15g / L, and the copper leaching rate was 98.21% 934g copper sulfate crystals were deposited from the leachate, with a recovery rate of 96.03%.

[0030] 3. Examples 6, 7, and 8 are examples of secondary mother liquor extraction and purification treatment.

Embodiment 6

[0031] In Example 6, the secondary mother liquor was extracted and treated with 5-nonylsalicylaldoxime.

[0032] Take 1 liter of the second mother liquor, adjust the mother liquor to contain Cu ++ 12g / L, P H It is 1.8, 15% extractant kerosene solution is added, and the extraction ratio is controlled to 1.5:1 for three-stage countercurrent extraction. The organic phase containing copper is subjected to secondary stripping with 180g / L dilute sulfuric acid, and the control ratio is 2.5:1. The stripping liquid contains 50g / L copper, and the raffinate contains less than 0.2g / L copper. The recovery rate was 98.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com