Method for selectively extracting copper from iron-copper-matte materials

A selectivity and material technology, applied in the direction of improving process efficiency, etc., can solve the problems of affecting the quality of cathode copper products and reducing the electrolysis efficiency of swirl electrolysis, achieving significant economic benefits, reducing copper ion concentration, and high electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Composition and weight percent of the iron-copper matte material: Pb26.43%, Cu49.65%, S12.37%, Ag0.4628%, Fe0.43%, As7.55%.

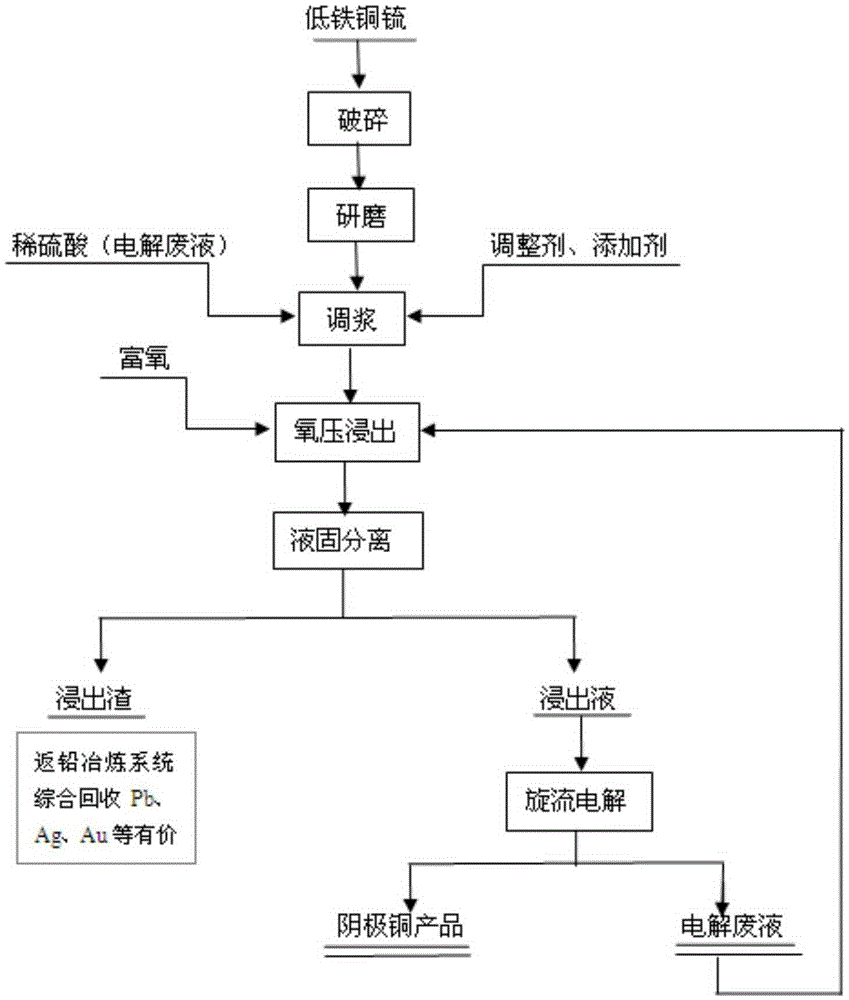

[0032] see figure 1, which is a process flow diagram for selectively extracting copper from iron-copper matte materials according to an embodiment of the present invention, specifically comprising the following steps:

[0033] Step 1, take 500 grams of the above-mentioned iron-copper matte material, crush and grind it to a particle size of 100 mesh, then mix it with dilute sulfuric acid, lignin, and pyrite powder, mix it in a pulping tank, and then pour it into an autoclave. Oxygen pressure leaching under the condition of continuously feeding oxygen enrichment, the oxygen pressure leaching conditions are: sulfuric acid concentration 115g / L, liquid-solid ratio 8:1, temperature 140°C, adjustment and maintenance pressure 1.2MPa, stirring speed 600r / min, Reaction time 3h.

[0034] Step 2: After the oxidation leaching is completed, the ore pulp is d...

Embodiment 2

[0043] Composition and weight percentage of the iron-copper matte material: Pb30.41%, Cu56.23%, S8.20%, Ag0.6312%, Fe0.24%, As12.75%.

[0044] see figure 1 , which is a process flow diagram for selectively extracting copper from iron-copper matte materials according to an embodiment of the present invention, specifically comprising the following steps:

[0045] Step 1, take 500 grams of the above-mentioned iron-copper matte material, crush and grind it to a particle size of 100 mesh, then mix it with dilute sulfuric acid, lignin, and pyrite powder, mix it in a pulping tank, and then pour it into an autoclave. Oxygen pressure leaching under the condition of continuously feeding oxygen enrichment, the oxygen pressure leaching conditions are: sulfuric acid concentration 100g / L, liquid-solid ratio 10:1, temperature 145°C, adjustment and maintenance pressure 1.4MPa, stirring speed 600r / min, The reaction time is 2.5h.

[0046] Step 2: After the oxidation leaching is completed, the...

Embodiment 3

[0055] Composition and weight percentage of the iron-copper matte material: Pb30.41%; Cu56.23%; S8.20%; Ag0.6312%; Fe0.24%; As12.75%.

[0056] see figure 1 , which is a process flow diagram for selectively extracting copper from iron-copper matte materials according to an embodiment of the present invention, specifically comprising the following steps:

[0057] Step 1, take 500 grams of the above-mentioned iron-copper matte material, crush and grind it to a particle size of 100 mesh, then mix it with dilute sulfuric acid, lignin, and pyrite powder, mix it in a pulping tank, and then pour it into an autoclave. Oxygen pressure leaching under the condition of continuously feeding oxygen enrichment, the oxygen pressure leaching conditions are: sulfuric acid concentration 100g / L, liquid-solid ratio 10:1, temperature 145°C, adjustment and maintenance pressure 1.4MPa, stirring speed 600r / min, The reaction time is 2.5h.

[0058] Step 2: After the oxidation leaching is completed, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com