Heap bioleaching method for secondary copper sulfide ore

A technology of copper sulfide ore and biopile, applied in the direction of improving process efficiency, etc., can solve the problem of inability to take into account efficient leaching of copper and inhibition of pyrite oxidation, pyrite oxidation cannot be effectively controlled, and no mention of oxidation control Reduce the concentration of reduction potential and other issues, achieve the effect of reducing the cost of neutralization of wastewater and the amount of neutralization slag, good prospects for popularization and application, and low oxidation rate of pyrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

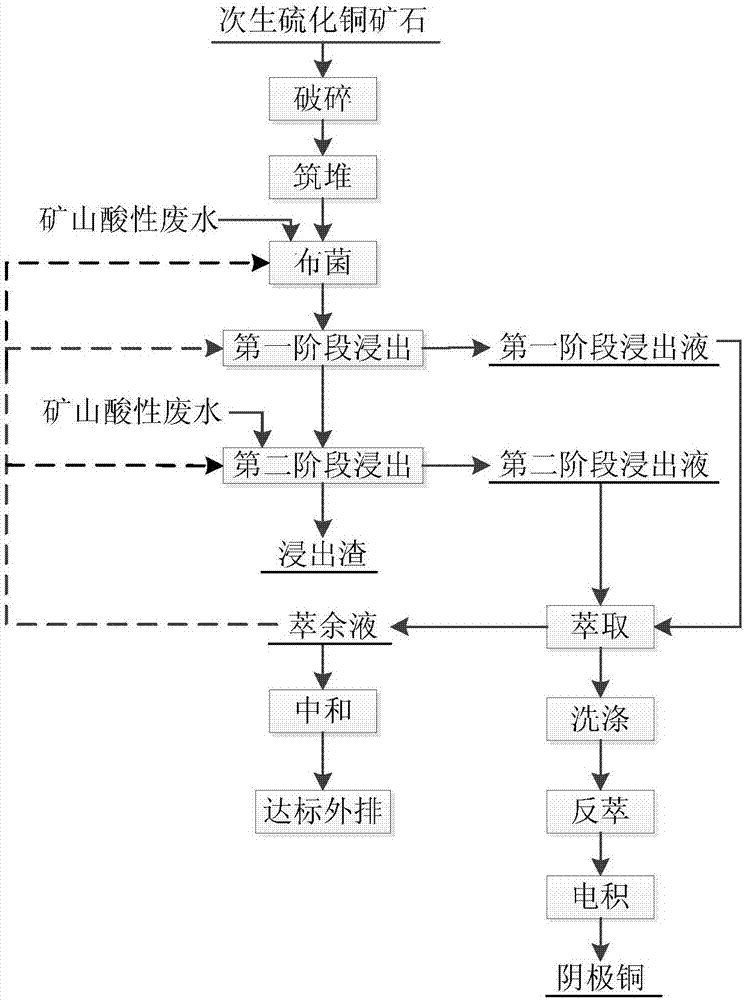

Method used

Image

Examples

Embodiment 1

[0028] The copper grade in a certain secondary copper sulfide ore is 0.40%, and the copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as pyrite, etc.; the content of pyrite is relatively high (4%-8 %), copper minerals and pyrite are closely symbiotic; gangue minerals are mainly quartz, and the content of acid-consuming gangue is low. The operation steps are as follows:

[0029] When the copper ore is crushed to -50mm ≥ 85%, use a truck to build a pile with a height of 10 meters; after the ore is piled up, immediately use the acidic wastewater from the mine to spray the ore to spread bacteria, and weld the spray pipe at the same time; After the welding is completed, use the raffinate (sulfuric acid concentration 8g / L, total iron concentration 8g / L, oxidation-reduction potential 750mV) for the first stage of continuous spraying, and the spraying intensity is 35L / h m 2 After the copper leaching rate reaches 50%, ...

Embodiment 2

[0032] The copper grade in a certain secondary copper sulfide ore is 0.40%, and the copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as pyrite, etc.; the content of pyrite is relatively high (4%-8 %), copper minerals and pyrite are closely symbiotic; gangue minerals are mainly quartz, and the content of acid-consuming gangue is low. The operation steps are as follows:

[0033] After the copper ore is crushed to -40mm ≥ 85%, the truck is used to build a pile with a height of 12 meters; after the ore is piled up, the ore is immediately sprayed with acidic wastewater from the mine to spread bacteria, and the spray pipe is welded at the same time; the spray pipe is welded After completion, use raffinate (sulfuric acid concentration 12g / L, total iron concentration 12g / L, redox potential 760mV) for the first stage of continuous spraying, spraying intensity 40L / h m 2 After the copper leaching rate reaches 50%, carry...

Embodiment 3

[0036] The copper grade in a certain secondary copper sulfide ore is 0.40%, and the copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as pyrite, etc.; the content of pyrite is relatively high (4%-8 %), copper minerals and pyrite are closely symbiotic; gangue minerals are mainly quartz, and the content of acid-consuming gangue is low. The operation steps are as follows:

[0037] When the copper ore is crushed to -50mm ≥ 85%, use a truck to build a pile with a height of 10 meters; after the ore is piled up, immediately use the raffinate (sulfuric acid concentration 8g / L, total iron concentration 8g / L, 750mV) spray wet ore, spread bacteria, and weld the spray pipe at the same time; after the spray pipe is welded, use the raffinate (sulfuric acid concentration 12g / L, total iron concentration 12g / L, redox potential 760mV) for the first stage Continuous spraying, spraying intensity 40L / h m 2 After the copper leachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com