Process for efficiently and selectively separating copper in lead copper matte

A selective and lead-separating technology, applied in photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of high temperature and high pressure in process conditions, inconvenient operation, etc., achieve low environmental pollution, low production cost, and short process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

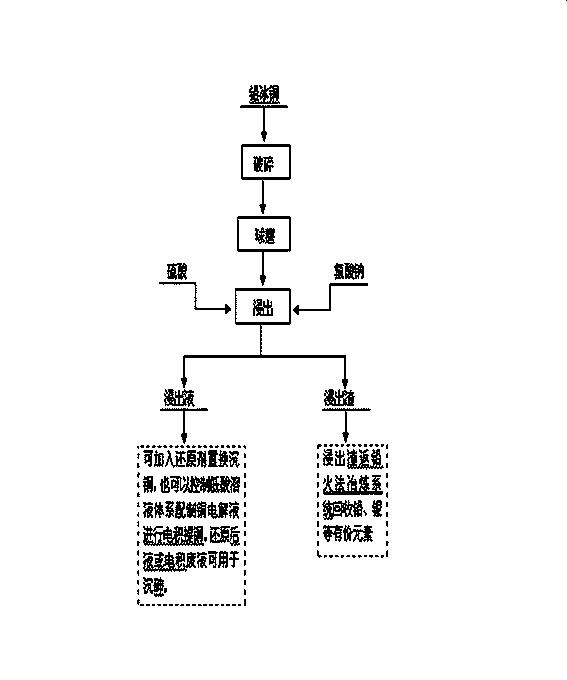

Method used

Image

Examples

Embodiment 1

[0021] 500 g of lead matte (Pb 26.58%; Cu 30.94%; S 9.88%; Ag 0.4684%; Fe 12.53%) was crushed, ball milled to a particle size of 70 mesh, and then moved into the leaching tank for leaching with sulfuric acid solution. Sodium chlorate, oxidation leaching copper, control conditions: oxidation potential 500mV, sulfuric acid concentration 1.0 mol / L, sodium chlorate concentration 300 g / L, liquid-solid ratio 6:1, temperature 70 ℃, stirring speed 300 r / min reaction time 3 h, normal pressure. After the leaching is completed, the liquid-solid separation is carried out, and Cu is divided into Cu 2+ After entering the leaching solution, the leaching rate of copper was found to be 93.43% through laboratory analysis, and the leaching slag tempering lead smelting system recovered valuable elements such as Ag and Pb. The silver recovery rate is 99.8%, and the lead recovery rate is >99.6%.

Embodiment 2

[0023] 500 g of lead matte (Pb 25.76%; Cu 29.99%; S 10.28%; Ag 0.5108%; Fe 13.66%) was crushed, ball milled to a particle size of 60 mesh, and then moved into a leaching tank for leaching with sulfuric acid solution. NaClO 3 , oxidative leaching of copper, control conditions: oxidation potential 600mV, sulfuric acid concentration 1.5 mol / L, sodium chlorate concentration 400 g / L, liquid-solid ratio 8:1, temperature 85 ℃, stirring speed 300 r / min, reaction time 5 h, Atmospheric pressure. After the leaching is completed, the liquid-solid separation is carried out, and Cu is divided into Cu 2+ After entering the leaching solution, the leaching rate of copper was found to be 97.88% through laboratory analysis, and the leaching slag tempering lead smelting system recovered valuable elements such as Ag and Pb. The recovery rate of lead and silver is more than 99.5%.

Embodiment 3

[0025] 500 g of lead matte (Pb 27.21%; Cu 30.88%; S 10.15%; Ag 0.4224%; Fe 14.10%) was crushed, ball milled to a particle size of 50 mesh, and then moved into a leaching tank for leaching with sulfuric acid solution. NaClO 3 , oxidative leaching of copper, control conditions: oxidation potential 700mV, sulfuric acid concentration 2.0 mol / L, sodium chlorate concentration 500 g / L, liquid-solid ratio 10:1, temperature 95 ℃, stirring speed 400 r / min, reaction time 5 h, Atmospheric pressure. After the leaching is completed, the liquid-solid separation is carried out, and Cu is divided into Cu 2+ After entering the leaching solution, the leaching rate of copper was found to be 97.65% through laboratory analysis, and the leaching slag tempering lead smelting system recovered valuable elements such as Ag and Pb. Among them, the lead recovery rate is 99.6%, and the silver recovery rate is 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com