Process for recycling valuable metal from lead copper matte

A valuable metal, lead matte technology, applied in the direction of photography process, photography auxiliary process, process efficiency improvement, etc., to achieve the effect of light environmental burden, low requirements for corrosion resistance conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

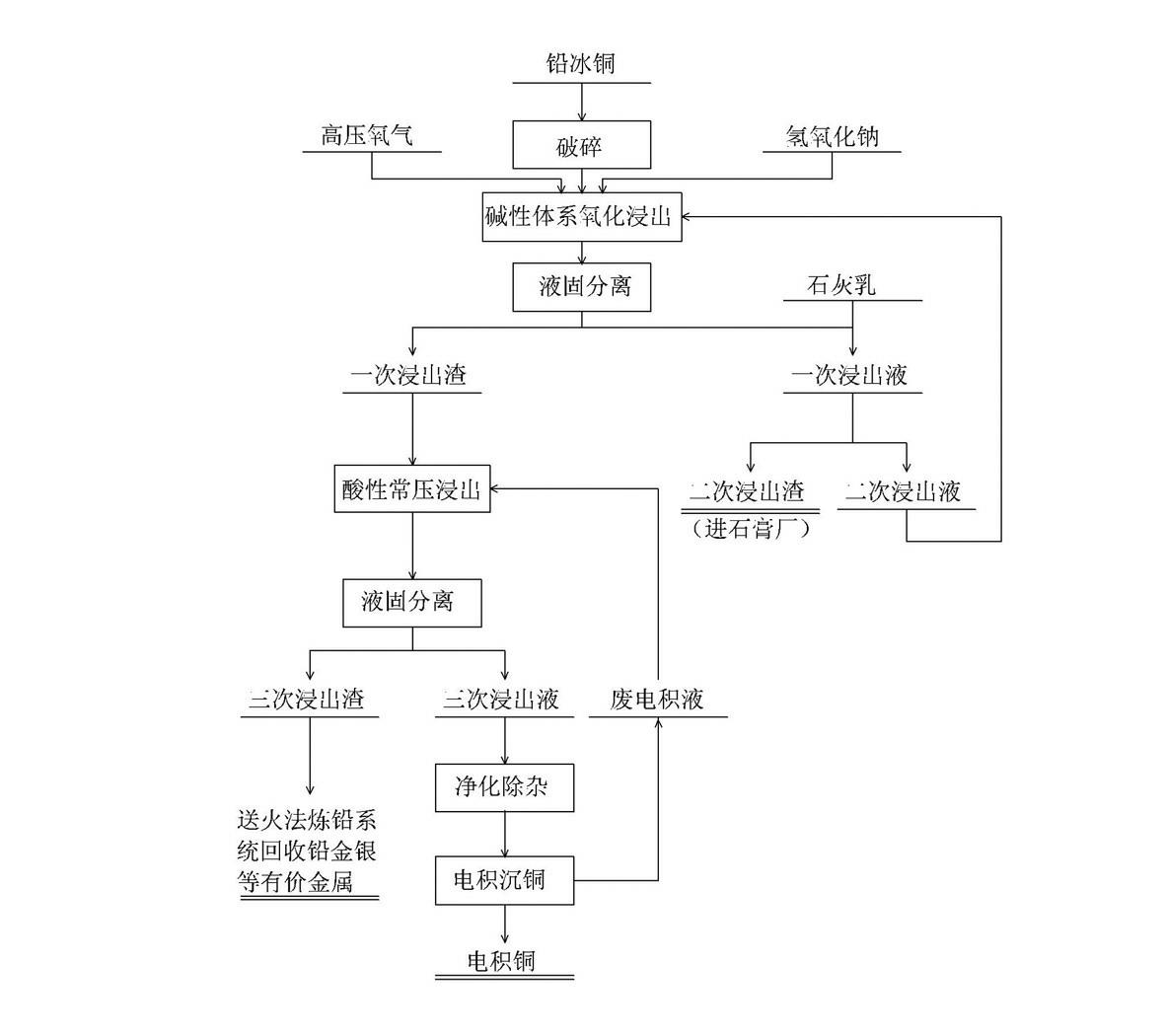

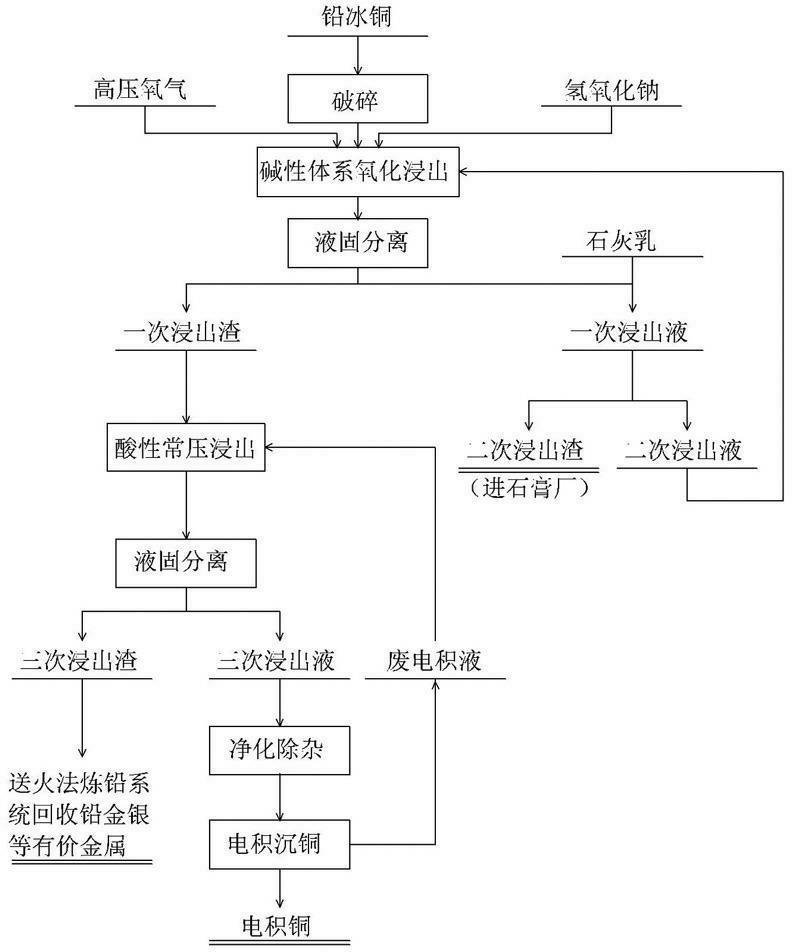

Method used

Image

Examples

example 1

[0025] A process for recovering valuable metals from lead matte, the chemical composition of lead matte used in a factory: Pb 5.89%, Cu 31.33%, Fe 28.12%, S 21.72%, SiO 2 0.3%, CaO 0.32%, Ag 0.0622%, Se 0.21%, Te 0.12%; in addition, there are a small amount of Sb, Sn, Zn and other elements. After the primary crushing treatment by the jaw crusher, the particle size of the material is less than 80 mesh after being ground by the ball mill. Weigh 200g of lead matte material, 199g of sodium hydroxide, and control the liquid-solid ratio to 4:1, pour it into a 2L small autoclave after slurry treatment, and stir and leaching for 6 hours at a temperature of 150-180°C , the stirring speed is controlled at 650r / min, the oxygen partial pressure is adjusted to 0.8MPa, and the total pressure in the kettle is maintained at 1.5MPa. After liquid-solid separation by a vacuum pump, 163.4 g of leaching residue was obtained, and the sulfur content in the residue was 0.94%. Add 1.4L of dilute su...

example 2

[0027] A process for recovering valuable metals from lead matte, the chemical composition of lead matte used in a factory: Pb 10.55%, Cu 38.42%, Fe 4.52%, S 15.72%, SiO 2 0.2%, CaO 0.47%, Ag 0.1622%. After the primary crushing treatment by the jaw crusher, the particle size of the material is less than 70 mesh after being ground by the ball mill. Weigh 304.6kg of lead matte, 143.6kg of sodium hydroxide, adjust the liquid-solid ratio to 3.5:1, and pump the material into the solution tank for 1m 3In the autoclave, the reaction temperature is controlled at 170-180 °C, the diameter of the stirring blade is 0.8 m, the speed is controlled at 120 r / min, the oxygen partial pressure is adjusted to 1.0 MPa, and the total pressure in the autoclave is maintained at 1.8 MPa. After 8 hours of leaching reaction, the liquid-solid separation operation was carried out. The desulfurization rate is 95.12%. All the obtained alkali leaching residues are sent to the middle tank for leaching in t...

example 3

[0029] A process for recovering valuable metals from lead matte, the chemical composition of lead matte used in a factory: Pb 10.70%, Cu 40.23%, Fe 3.68%, S 11.952%, SiO 2 0.5%, CaO 0.41%, Ag 0.1310%. After the primary crushing treatment by the jaw crusher, the particle size of the material is less than 60 mesh after being ground by the ball mill. Weigh 350kg of lead matte, 160kg of sodium hydroxide, adjust the liquid-solid ratio to 3:1, and pump the material into the solution tank for 1m 3 In the autoclave, the reaction temperature is controlled at 180-200 °C, the diameter of the stirring blade is 1.0 m, the speed is controlled at 100 r / min, the partial pressure of oxygen is adjusted to 1.2 MPa, the total pressure in the autoclave is maintained at 2.2 MPa, and the leaching reaction is carried out after 7 hours. Solid separation operation. The desulfurization rate is 96.2%. All the obtained alkali leaching residues are sent to the middle tank for leaching in acidic system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com