Preparation method for porous monolithic column immobilized enzyme micro-reactor

A technology of immobilized enzymes and microreactors, applied in the direction of supporting/immobilizing microorganisms, enzyme production/bioreactors, biochemical equipment and methods, etc. Long service life, high enzyme activity and low back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of porous monolithic column immobilized α-glucosidase microreactor and its application

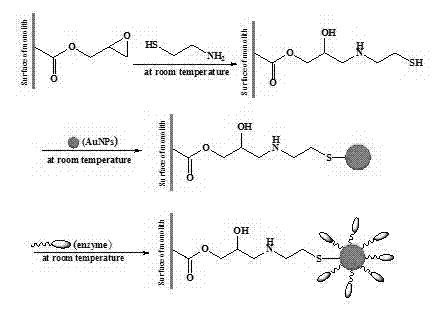

[0023] refer to figure 1 , the preparation method of porous monolithic column immobilized enzyme microreactor, concrete steps are as follows:

[0024] (1) Synthesis of gold nanoparticles

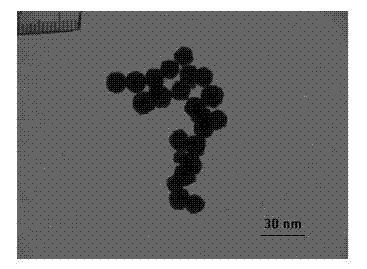

[0025] Measure 100mL of deionized water and place it in a 250mL round-bottomed flask, heat to reflux with stirring until boiling, then add 1mL of 1% (w / w) chloroauric acid, then continue to heat until the solution boils violently, quickly add 2.5 mL 1% (w / w) sodium citrate, continue to keep the solution boiling for 15min. During this time the color of the solution changed from gray to wine red. Naturally cool to room temperature after removing the heat source, figure 2 It is a transmission electron microscope image of the prepared gold nanoparticles, and it can be seen from the figure that the gold nanoparticles are spherical, and the particle diameter is about 15nm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com