Electrospinning device for dynamically controlling curvature of spinning solution and application method for electrospinning device

An electrospinning, dynamic control technology, applied in electrospinning, textile and papermaking, filament/thread forming, etc., can solve the problems of uncontrollable solution curvature and volatile solution to be spun, and achieve stable and controllable production. , the effect of optimizing the critical voltage and expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

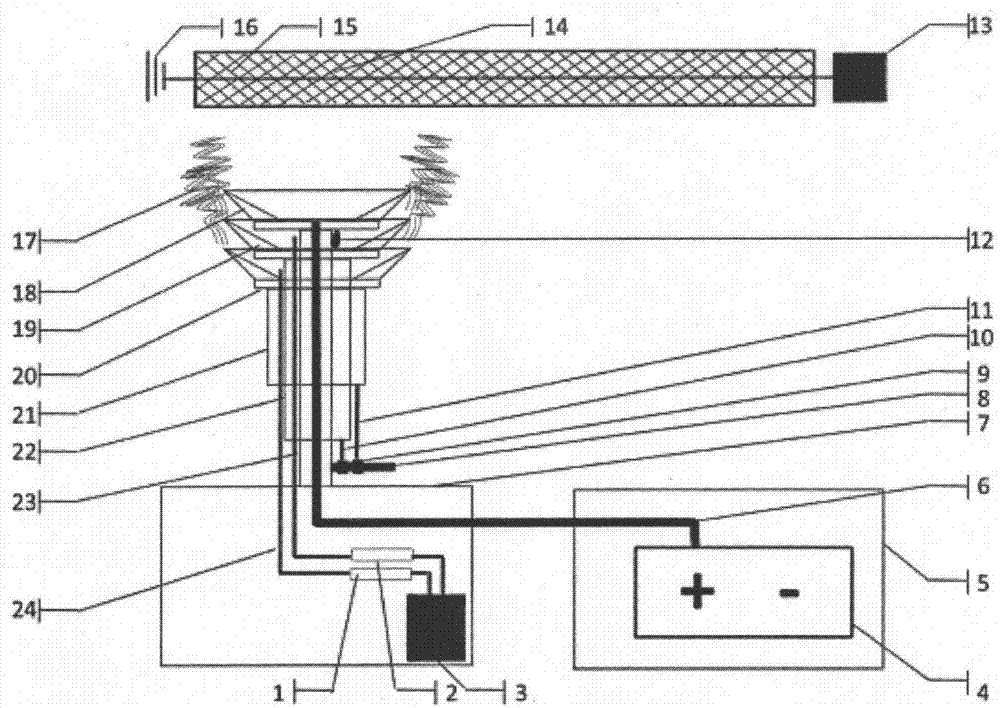

[0052] Such as figure 1 As shown, an electrospinning device with dynamic control of spinning solution curvature provided in this embodiment includes a solution supply system, an electric field control system, a spinning solution curvature control system and a nanofiber collection system.

[0053] The liquid supply system includes a liquid storage tank 3 , a peristaltic propulsion pump 1 , a peristaltic propulsion pump 2 2 , and a catheter 24 . The catheter 24 is connected to the liquid storage tank 3 and the first disc nozzle 18, the second disc nozzle 19, the third disc nozzle 20, the peristaltic propulsion pump 1, and the peristaltic propulsion pump 2 2 The peristaltic extrusion spinning solution enters the nozzle quantitatively.

[0054] The electric field control system is composed of multiple sets of disc nozzles made of metal. The first disc nozzle 18 is made of metal, which is connected to the positive pole of the high voltage generator 4 through the conductive rod 6 ....

Embodiment 2

[0089] Narrowly distributed nanofibers were prepared using a polymer solution configured with polyacrylonitrile (PAN) and N-N dimethylformamide (DMF):

[0090] Configure the mass fraction of the PAN polymer solution to be 10%. Build a four-layer device, each layer is a dish-shaped disc nozzle made of metal; inject the prepared polymer solution into the liquid storage tank 3; open the screw distance control device for each layer, set the end position of the insulating screw rod so that each The layer spacing is equal to 5mm; turn on the peristaltic propulsion pump 1, peristaltic propulsion pump 2 2, etc. to supply liquid to the dish-shaped disc nozzle until the liquid level between the layers is close to full; adjust the height of the metal cylinder 15 so that the horizontal plane of the central axis is in line with the The distance between the upper surface of the disc-shaped disc nozzle on the top layer is 20cm; turn on the motor three 13 and set the rotating speed to be 80r / ...

Embodiment 3

[0092] Multi-level narrow distribution nanofibers were prepared using a polymer solution configured with polyacrylonitrile (PAN) and N-N dimethylformamide (DMF):

[0093] Build a six-layer device, each layer is a disc-shaped disc nozzle made of metal; inject the prepared polymer solution into the liquid storage tank 3; turn on the peristaltic propulsion pump 1, peristaltic propulsion pump 2, etc. The disc nozzle supplies liquid until the liquid level between each layer is close to full; open the screw distance control device of each layer, set the end position of the insulating screw rod so that the distance between each layer is equal to 8mm, and make the edge curvature of the spinning liquid be the set value; adjust The height of the metal drum 15 is such that the distance between the horizontal plane of the central axis and the upper surface of the uppermost dish-shaped disc nozzle is 18cm. Turn on the motor three 13 and set the rotating speed to 70r / min; turn on the high vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com