CsPbBr3 fully-inorganic perovskite nano wire based visible light photoelectric detector and preparation method thereof

A technology of nanowires and inorganic calcium, applied in the field of inorganic perovskite nanowire thin films, can solve the problems of insufficient production of high-performance photodetectors, complex vacuum coating technology, destroying ligands, etc., and achieves low cost of experimental raw materials, Good photoelectric response performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

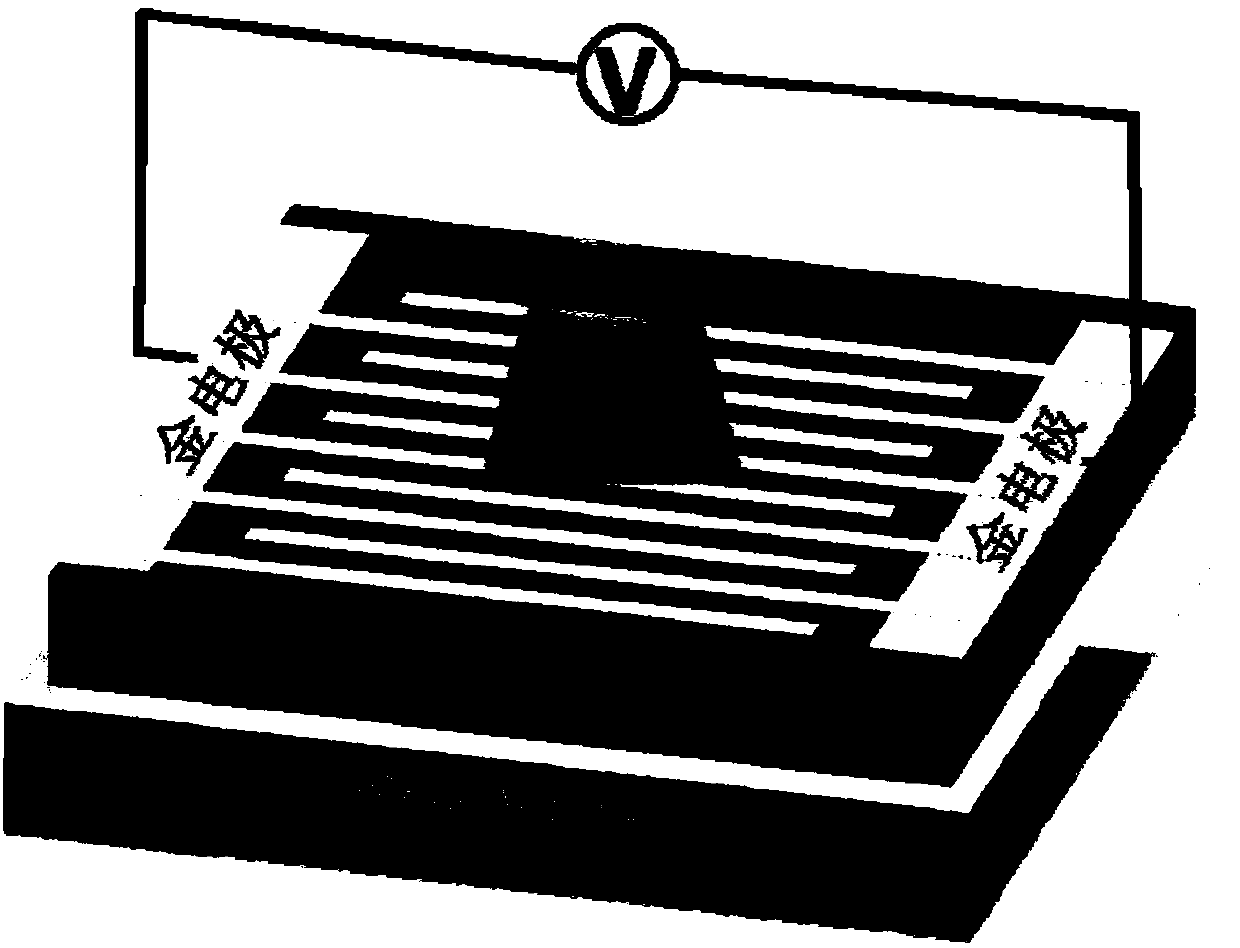

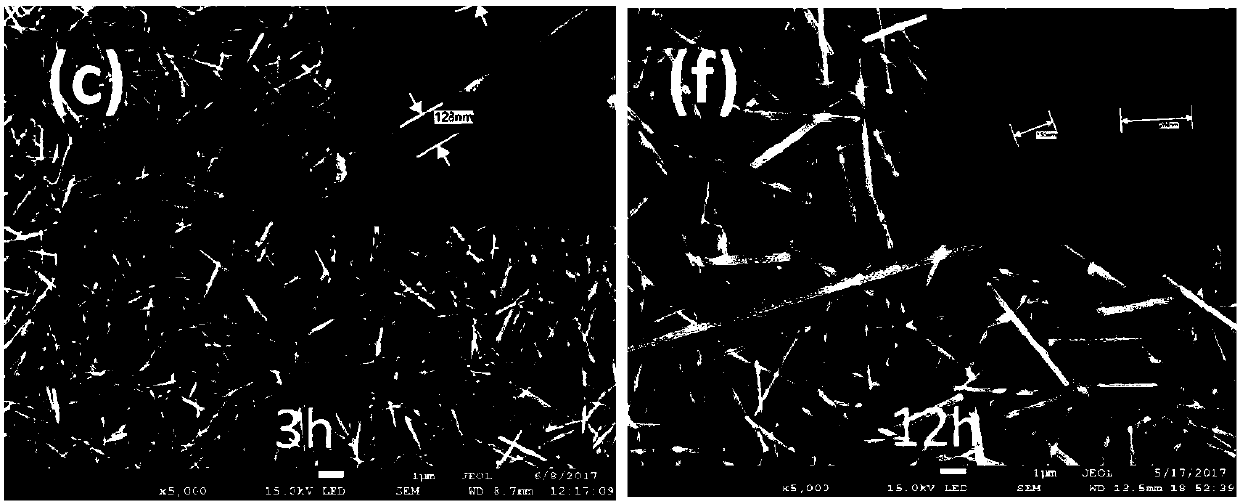

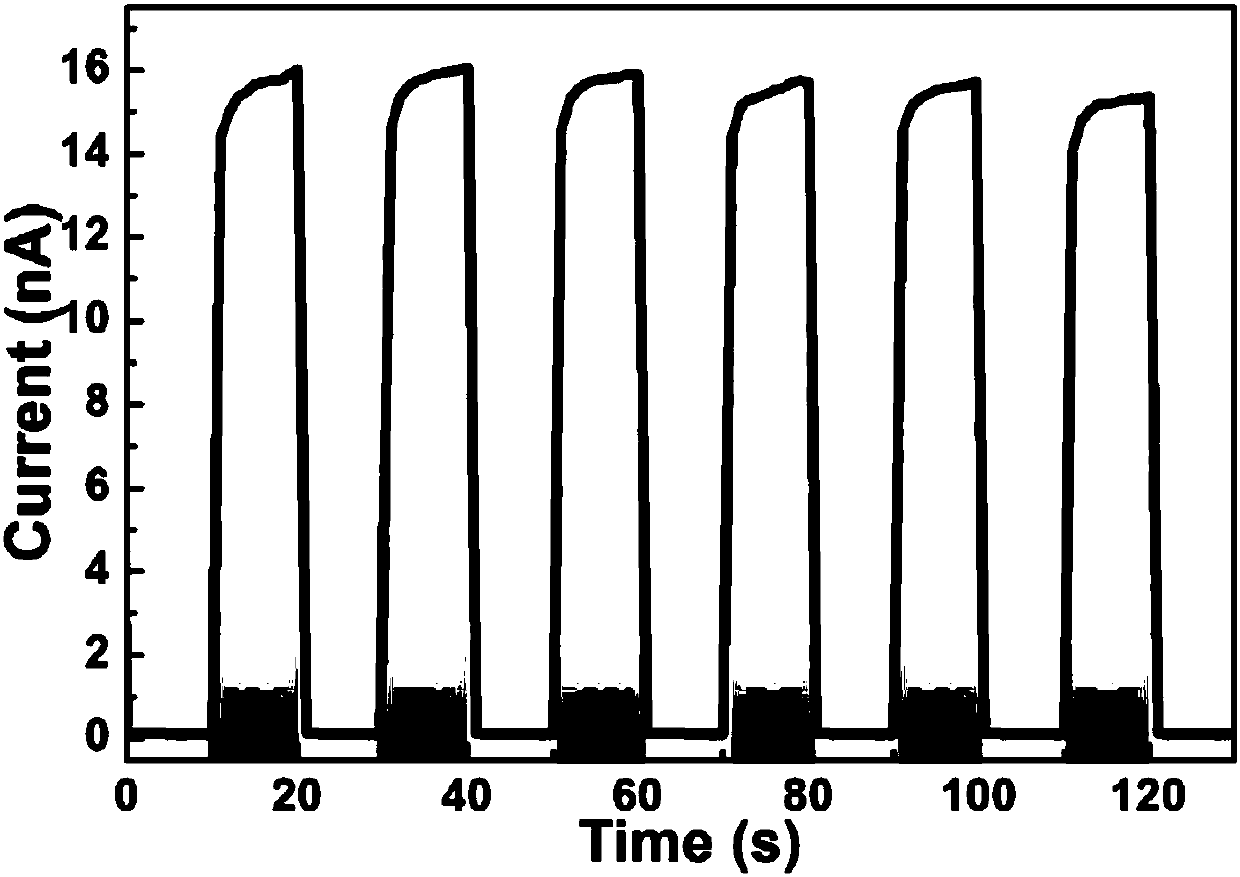

[0040] Example 1: Different growth time CsPbBr 3 Fabrication of Perovskite Nanowire Detectors:

[0041] (1) Ultrasonic the transparent glass substrate with deionized water, acetone, and alcohol for 20 minutes respectively, and then treat it with ultraviolet ozone environment for 30 minutes;

[0042] (2) Preparation of non-perovskite phase CsPbI by soap-free solution method 3 nanowire film

[0043] 1M PbI 2 Dissolve in DMF (N,N-dimethylformamide), incubate at 70°C for 12 hours to fully dissolve, then filter for later use; dissolve CsI in methanol solution and stir for 20 minutes for later use; PbI 2 The solution was spin-coated on a transparent glass substrate at 5000 rpm for 60 seconds, and then dried on a hot stage. After 15 minutes, the PbI 2 The substrate of the film is soaked in CsI / methanol solution for 3-12 hours, and then dried;

[0044] (3) The non-perovskite phase CsPbI was synthesized by ion exchange method 3 Nanowire film conversion to non-perovskite phase CsP...

Embodiment 2

[0051] Example 2: CsPbBr annealed at different temperatures 3 Fabrication of perovskite nanowire detectors:

[0052] (1) Ultrasonic the transparent glass substrate with deionized water, acetone, and alcohol for 20 minutes respectively, and then treat it with ultraviolet ozone environment for 30 minutes;

[0053] (2) Preparation of non-perovskite phase CsPbI by soap-free solution method 3 nanowire film

[0054] 1M PbI 2 Dissolve in DMF (N,N-dimethylformamide), incubate at 70°C for 12 hours to fully dissolve, then filter for later use; dissolve CsI in methanol solution and stir for 20 minutes for later use; PbI 2 The solution was spin-coated on a transparent glass substrate at 5000 rpm for 60 seconds, and then dried on a hot stage. After 15 minutes, the PbI 2 The substrate of the film was soaked in CsI / methanol solution for 6 hours, and then dried;

[0055] (3) The non-perovskite phase CsPbI was synthesized by ion exchange method 3 Nanowire film conversion to non-perovskit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com