Process for electrolytic pickling using nitric acid-free solutions

a technology of electrolysis and nitric acid, which is applied in the direction of crystal growth process, separation process, manufacturing tools, etc., can solve the problems of nitric acid replacement in electrolysis process applications typical of processes a) and c) and has not yet been solved, and nitric acid alone does not enable the same standards of surface roughness, opacity and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

To provide an example, an electrolytic pickling process according to the present invention will now be described for the treatment of a continuous strip of cold-rolled stainless steel sheet of the ferritic type (series 400) having a width of 1200 mm, previously treated with molten salts according to step A.1.

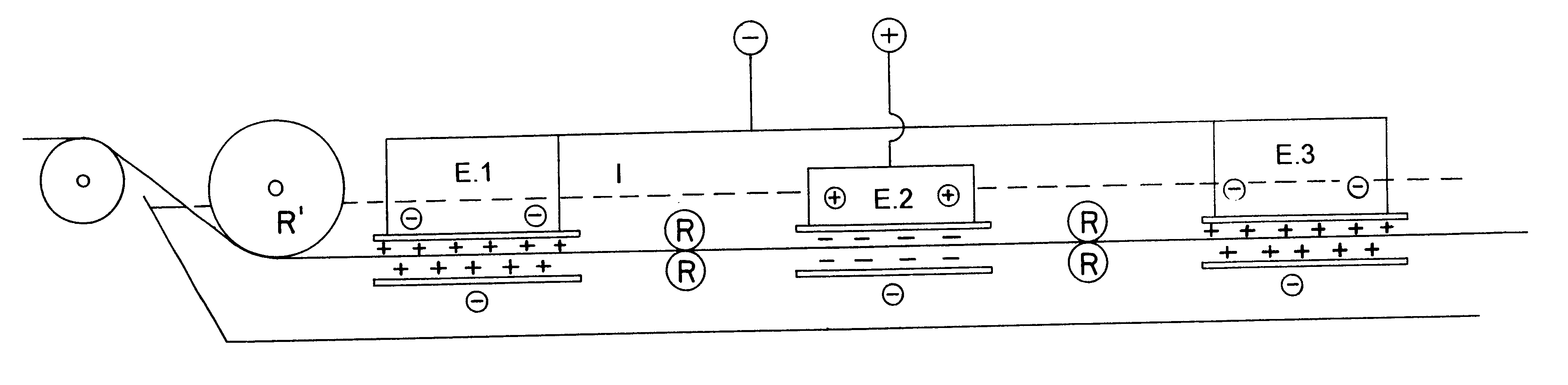

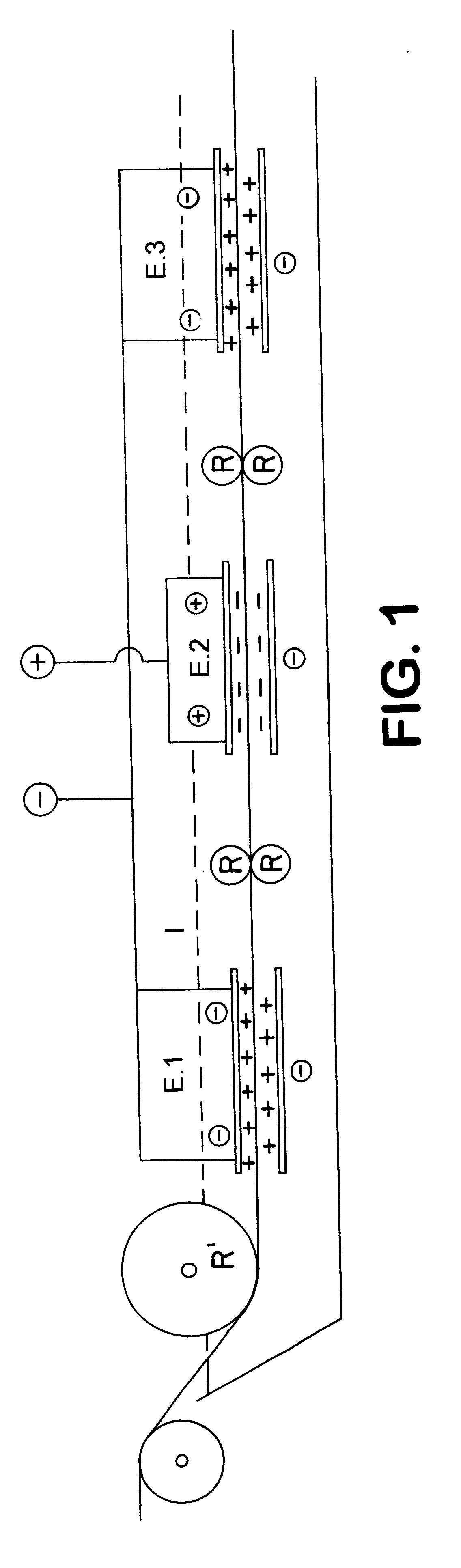

The electrolytic apparatus adopted is represented schematically in FIG. 1 as regards the essential structural elements and comprises a rectangular tank in which the useful path length of the strip in contact with the solution is 17.5 m.

FIG. 1 illustrates only the first basic electrolytic unit (module) supplied with electric current having an intensity of 3700 A. This is followed by a second, similar unit supplied with a 2100-A current.

In the diagram of FIG. 1, the first electrolytic region E.1 is represented, where the cathodic counter-electrode consists of a rectangular plate set beneath the strip, having the side parallel to the path of the strip 1200 mm long and the transvers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com