Methods for forming a barrier layer with periodic concentrations of elements and structures resulting therefrom

a technology of barrier layer and periodic concentration, applied in the field of processing a microelectronic topography, can solve the problems of affecting the fabrication specifications of film depositing, affecting the uniformity of thickness, and affecting the quality of the final produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

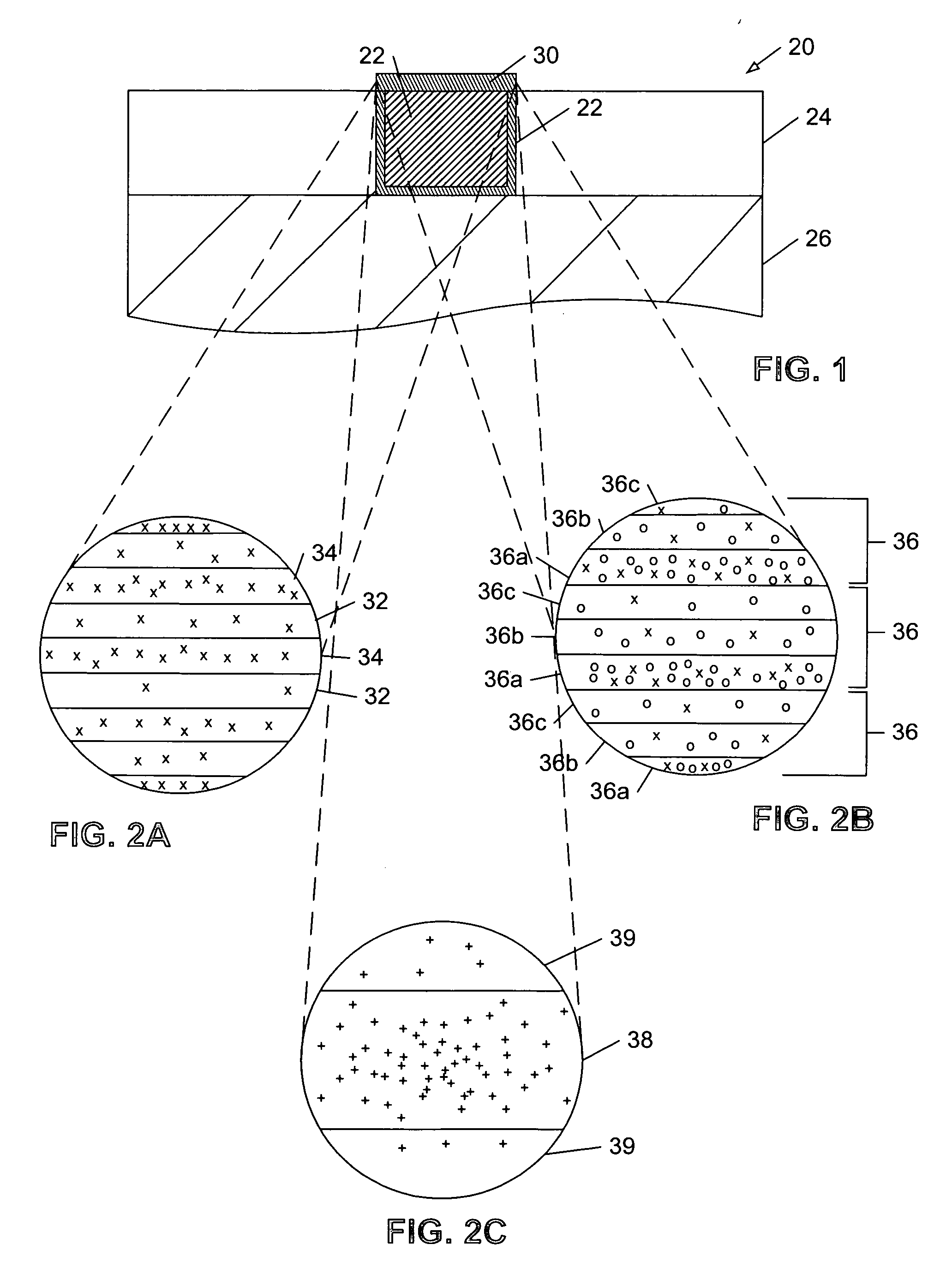

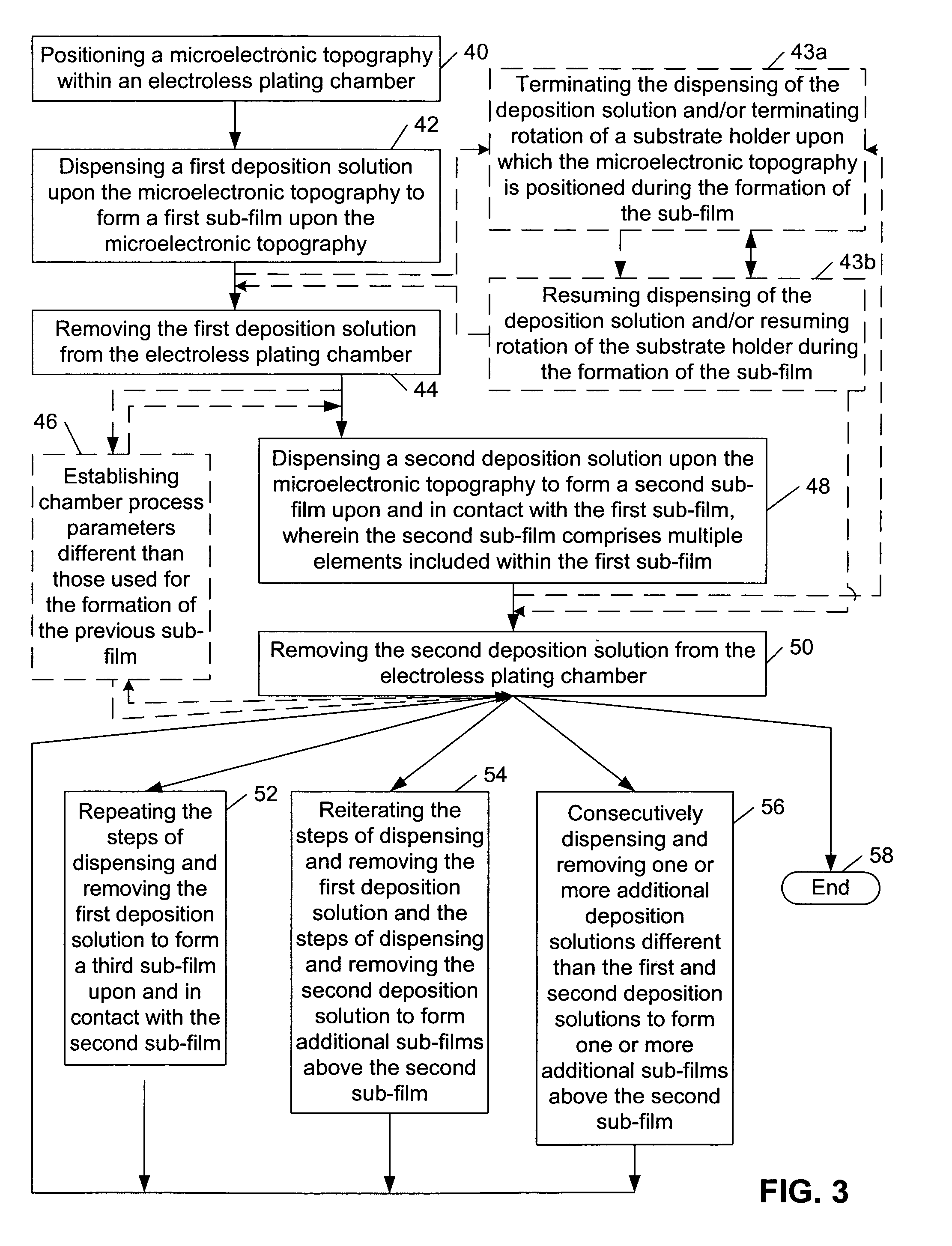

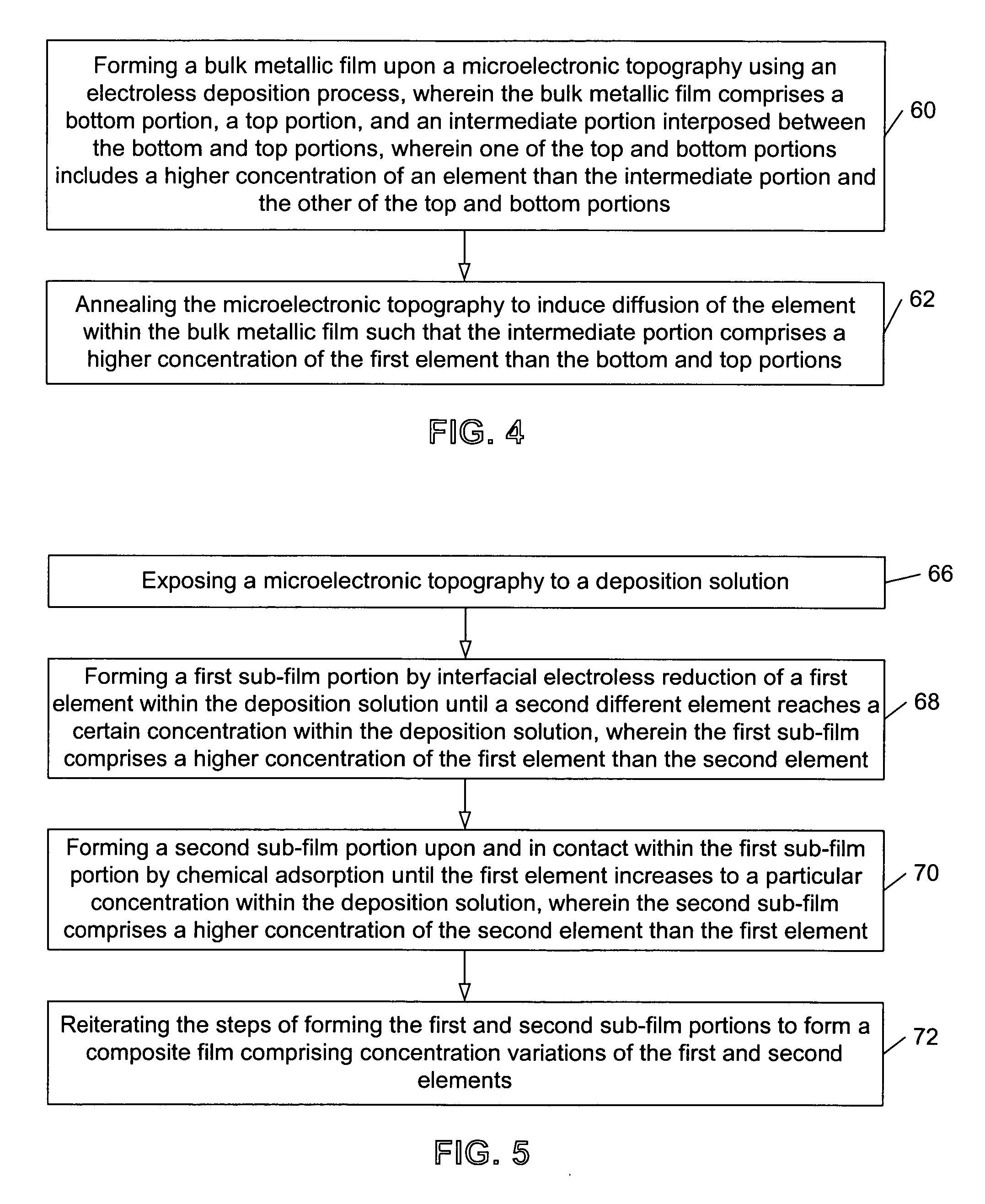

[0038] Turning to the drawings, exemplary methods and systems involving electroless plating processes for the formation of metallic layers and structures within microelectronic topographies are shown. In addition, microelectronic topographies resulting from the use of such methods and systems are shown. For instance, FIG. 1 illustrates a partial cross-sectional view of microelectronic topography 20 having liner layer 28, cap layer 30, as well as other metallic structures which may be formed from the methods and systems described below in reference to FIGS. 3-13. Although the methods and systems described below are specifically discussed in reference to the formation of barrier layers and, therefore, are specific to liner layer 28 and cap layer 30, any of the metallic structures of microelectronic topography 20, including those formed below lower layer 26 and those formed above cap layer 30, may be formed by the methods and systems described below in reference to FIGS. 3-13.

[0039] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com