Steel wire rod for 1860MPa-level bridge cable galvanized steel wire and manufacturing method thereof

A technology of galvanized steel wire and manufacturing method, applied in the field of high carbon steel wire rod production, can solve the problems of environmental and worker health hazards, reduction of yield, energy consumption and cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with embodiment.

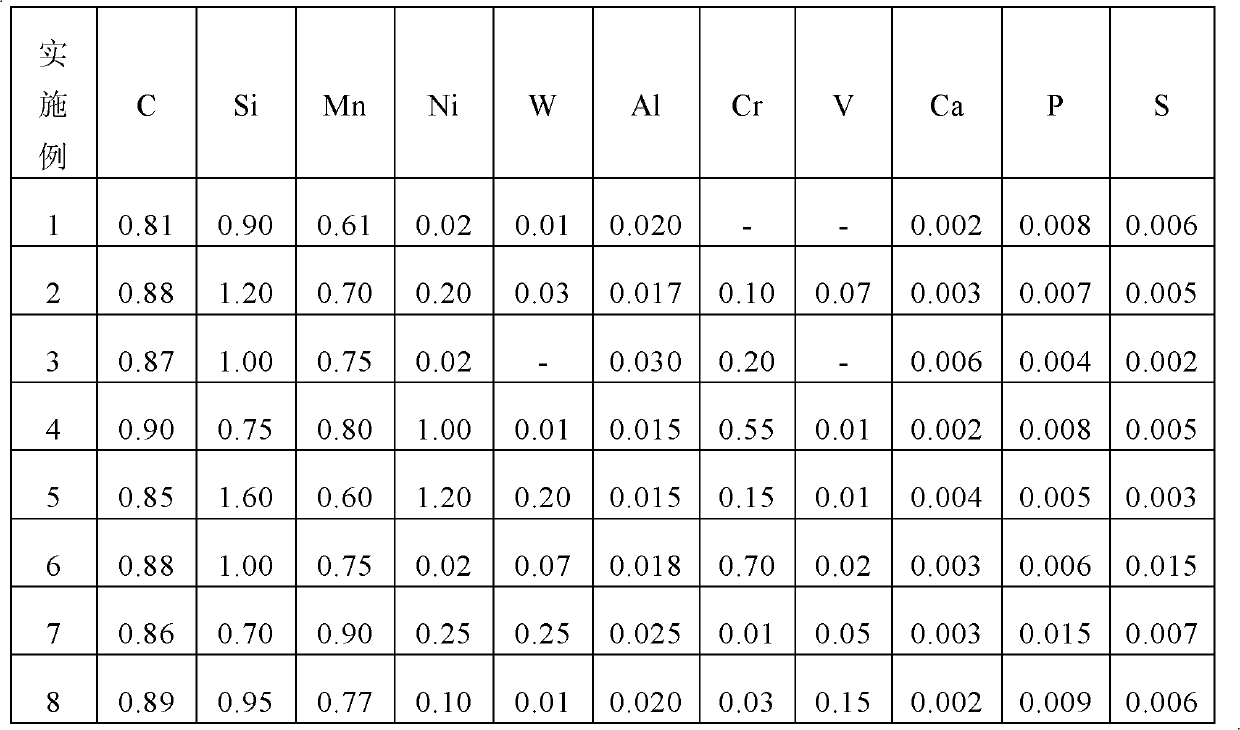

[0045] The chemical compositions of the high-grade galvanized steel wire rod products of Examples 1-8 of the present invention shown in Table 1 are as follows.

[0046] The preparation method of the wire rod of embodiment 1-8 is as follows:

[0047] After the alloy is smelted in an electric furnace or a converter, it is smelted in an LF furnace and treated with VD; the smelting process in an electric furnace or a converter is carried out in accordance with the low N and low P operation method, and the blowing process is controlled by positive pressure. The P element content in the steel is less than 0.015%. In the LF treatment project, the alkali-forming slag is fully desulfurized until the S element content is lower than 0.015%, and argon is blown at the bottom. The VD vacuum treatment process adopts soft argon blowing operation, and the degassing time must be longer than 25 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com