Method for directly growing nano-crystal chromium nitride film on steel products

A nanocrystalline and chromium nitride technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of complex technology, retention, and difficulty in industrialized mass production, and achieve low temperature and energy saving , Broaden the effect of industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

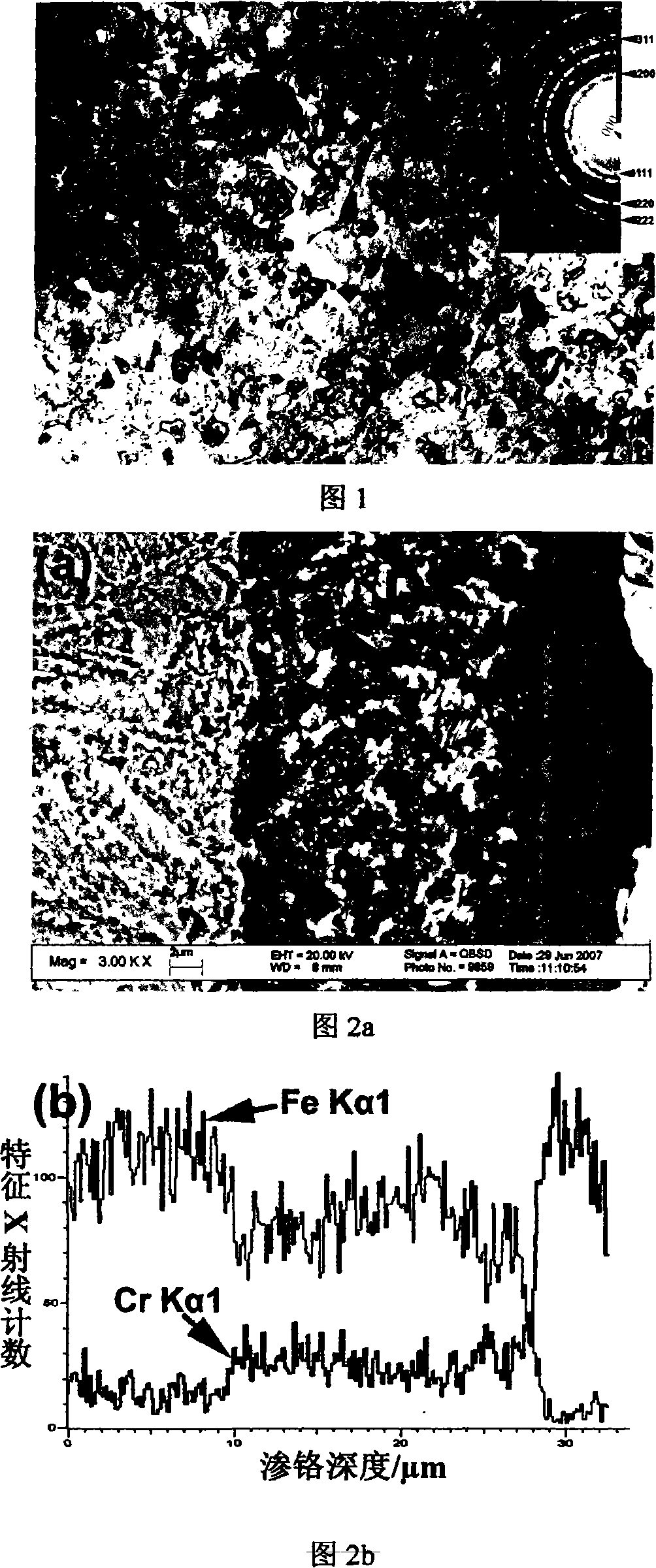

Embodiment 1

[0039] 20 steel, after normalizing, then pre-treat the surface, polish and degrease. Then carry out ion nitriding at 540°C for 8 hours. The ion nitriding uses a bell-type furnace with a low vacuum of 50Pa and a medium of 0.5m 3 / h ammonia gas. After cooling to room temperature with the furnace, the surface is slightly cleaned, and then chromized in a salt bath at 650 ° C for 3 hours. The salt bath chromizing step is as follows: first melt the uniformly mixed base salt at about 620°C in the crucible (add CrCl at this temperature 3 ·6H 2 O, can reduce volatilization), and then gradually, in small batches, slowly add CrCl to the molten base salt 3 ·6H 2 O; to be added to all CrCl 3 ·6H 2 After adding O to the molten base salt, keep it warm until CrCl 3 ·6H 2 O and the base salt are completely melted and stirred evenly; then the temperature control is adjusted to a pretreatment temperature of 650°C, and the evenly mixed Cr powder, Fe powder and Si powder are added to the sa...

Embodiment 2

[0041] 20 steel, after normalizing, then pre-treat the surface, polish and degrease. Then carry out ion nitriding at 540°C for 8 hours. The ion nitriding uses a bell-type furnace with a low vacuum of 50Pa and a medium of 0.5m 3 / h ammonia gas. After cooling to room temperature with the furnace, the surface is slightly cleaned, and then chromized in a salt bath at 650 ° C for 6 hours. The salt bath chromizing step is as follows: first melt the uniformly mixed base salt at about 620°C in the crucible (add CrCl at this temperature 3 ·6H 2 O, can reduce volatilization), and then gradually, in small batches, slowly add CrCl to the molten base salt 3 ·6H 2 O; to be added to all CrCl 3 ·6H 2 After adding O to the molten base salt, keep it warm until CrCl 3 ·6H 2 O and the base salt are completely melted and stirred evenly; then the temperature control is adjusted to a pretreatment temperature of 650°C, and the evenly mixed Cr powder, Fe powder and Si powder are added to the s...

Embodiment 3

[0043] 20 steel, after normalizing, then pre-treat the surface, polish and degrease. Then carry out ion nitriding at 540°C for 8 hours. The ion nitriding uses a bell-type furnace with a low vacuum of 50Pa and a medium of 0.5m 3 / h ammonia gas. After cooling to room temperature with the furnace, the surface is slightly cleaned, and then chromized in a salt bath at 580 ° C for 12 hours. The salt bath chromizing step is as follows: first melt the uniformly mixed base salt at 620°C in the crucible (add CrCl at this temperature 3 ·6H 2 O, can reduce volatilization), and then gradually, in small batches, slowly add CrCl to the molten base salt 3 ·6H 2 O; to be added to all CrCl 3 ·6H 2 After adding O to the molten base salt, keep it warm until CrCl 3 ·6H 2 O and the base salt are completely melted and stirred evenly; then the temperature control is adjusted to the pretreatment temperature of 580°C, and the evenly mixed Cr powder, Fe powder and Si powder are added to the salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com