Method for producing tempered glass with plurality of surface stress layers and tempered glass product

A tempered glass, surface compressive stress technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems that do not involve multi-step tempering of lithium-aluminosilicate glass, etc., to achieve high strength, reliable protection, and reliability guarantee Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

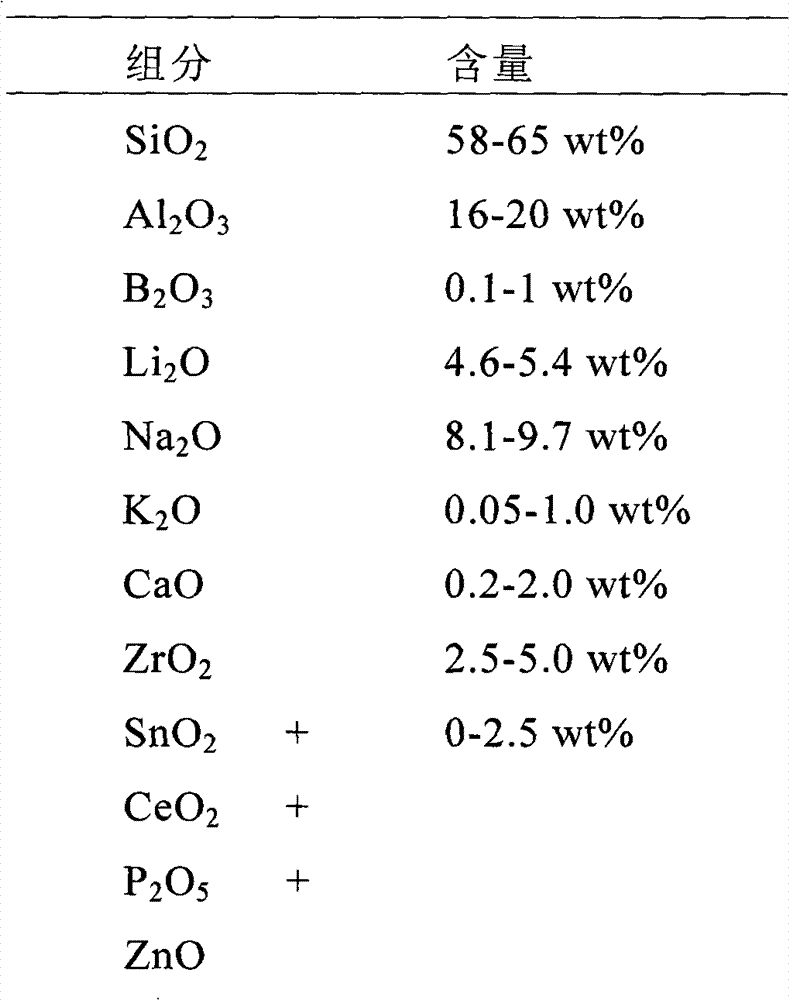

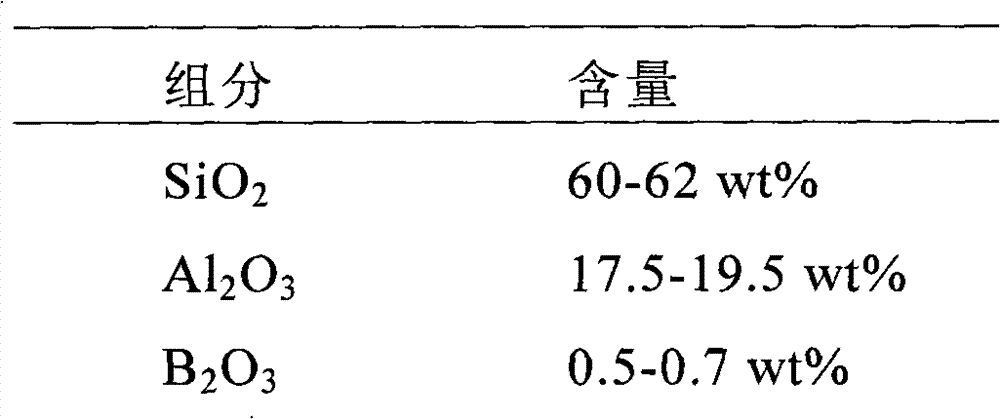

[0121] The glass in Example 1 is melted using oxides, hydroxides and carbonates as raw materials. After weighing and mixing, the mixture is put into a platinum crucible, and it is made on an electric furnace at 1550-1600°C. It is melted, then cast into a metal mold preheated to a suitable temperature, and then slowly cooled to produce a bulk glass, which is then precisely annealed at annealing temperature to relieve internal stress. The precision annealed glass was cut into thin slices, then polished on both sides and edged with a CNC machine tool to obtain a glass sample of 100x60x0.7mm.

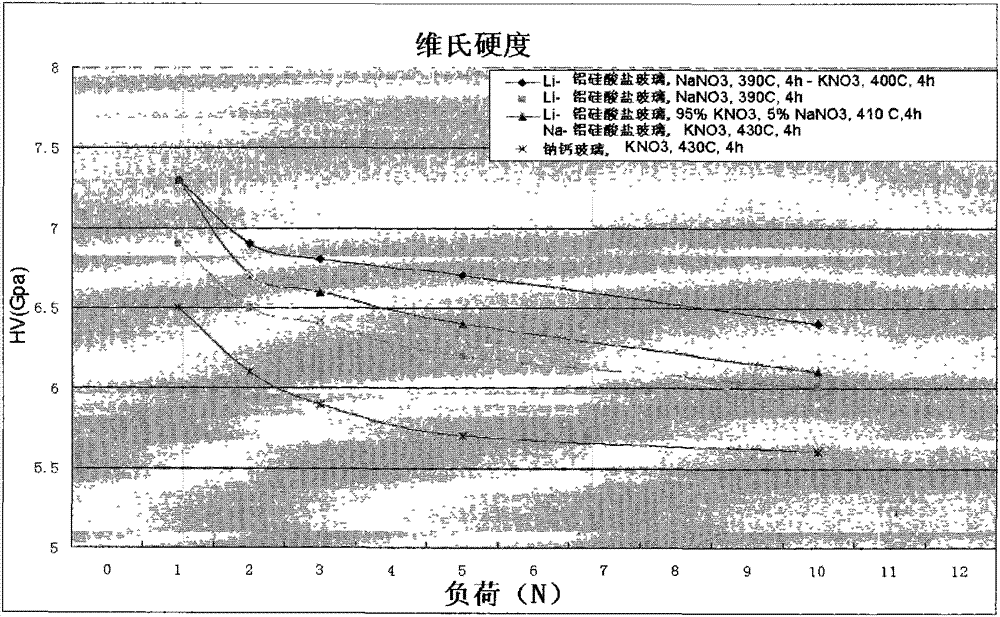

[0122] The glass samples were chemically tempered by a two-step method, in which the molar ratio of Li:Na:K in the molten salt used in the first step was 0.1:99.8:0.1, the glass samples were immersed in the molten salt, tempered at 390°C for 4 hours, and then The glass is removed from the molten salt, cooled to room temperature, rinsed with clean water and dried. Then immersed in the secon...

Embodiment 2

[0125] The process of glass melting and glass sample preparation in Example 2 is the same as that in Example 1. The glass samples were tempered by one-step mixed molten salt, the molar ratio of Li:Na:K in the molten salt was 0.1:5:95, both were prepared with nitrate, and the glass samples were tempered at 410°C for 4 hours by immersing in the molten salt. The tempered glass has K DoL of 15μm and Na DoL of 136μm, surface compressive stress of 710MPa and 670kgf / mm 2 Vickers hardness.

Embodiment 7

[0126] The glass melting and glass sample preparation process in Example 7 are the same as in Example 1. The glass samples were tempered in molten salt in three steps, in which the molar ratio of Li:Na:K in the molten salt used in the first step was 0.1:98.9:1, the glass samples were immersed in the molten salt and tempered at 390 °C for 4 hours, and then Take the glass out of the first molten salt, immerse it directly in the second molten salt without cooling, wherein the molar ratio of Li:Na:K is 0.2:4.8:95, temper at 410°C for 0.3 hour, and then remove the glass from the second molten salt Take it out from the second molten salt, immerse it directly in the third molten salt without cooling, wherein the molar ratio of Li:Na:K is 0.02:0.2:99.78, and temper at 420° C. for 4 hours. The molten salts in the first step, the second step and the third step are all prepared by using corresponding alkali metal nitrates. The tempered glass has K DoL of 21μm and Na DoL of 162μm, surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface compressive stress | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com