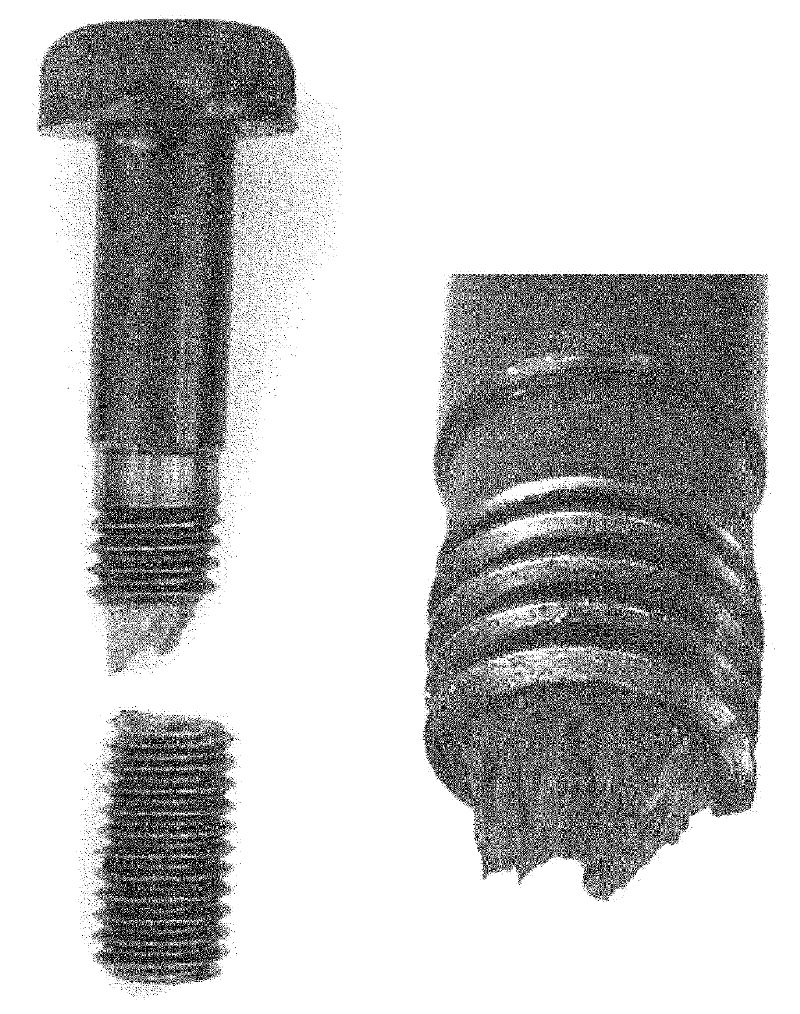

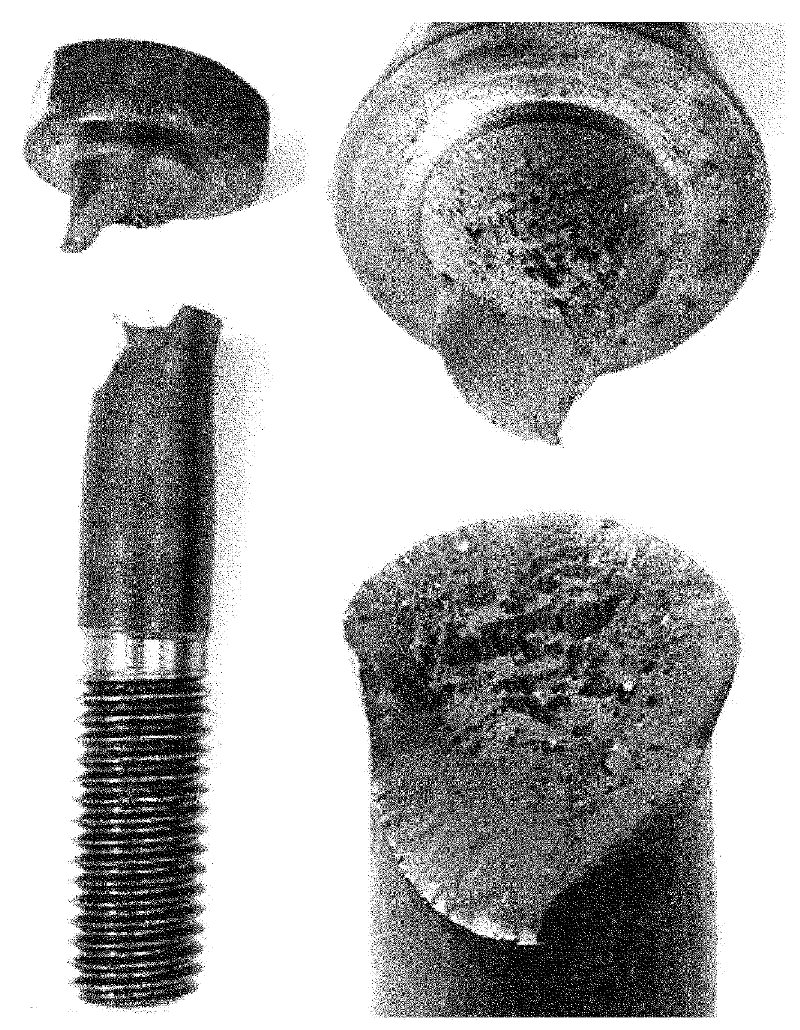

High-strength bolt

一种高强度螺栓、抗拉强度的技术,应用在螺钉、螺纹紧固件、炉子类型等方向,能够解决螺栓形状和尺寸制约、无法冲击韧性改善等问题,达到耐冲击性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

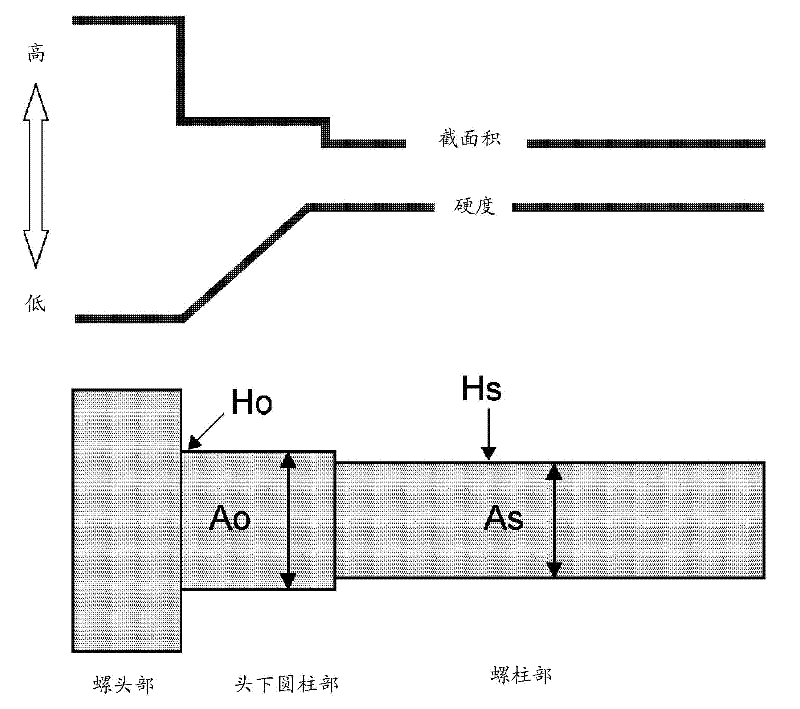

[0062] Table 1 shows the steel composition used in the bolt material. The A material has a steel material component excellent in delayed fracture characteristics disclosed in Patent Document 2, and the B material corresponds to JIS-SCM440 steel. As a tempering material, prepare a cross-sectional area of about 2 cm 2 of bars. Material A and material B were quenched at 950°C and 920°C respectively, and then tempered at 500°C and 400°C for 1 hour. On the other hand, for particle-dispersed fibrous tissue materials, first prepare 2 For the square bar, material A and material B were quenched at 950°C and 920°C, respectively, to obtain a single structure of martensite approximately close to 100% by volume. It should be noted that the prior austenite grain size in the quenched structure is about 50 μm. Next, material A and material B were tempered at 500°C and 400°C for 1 hour respectively, and then the cross-section was shrunk to a cross-sectional area of 2 cm using a grooved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com