High-strength hot-formed steel sheet member

a technology of hot-formed steel and high-strength, which is applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of dimensional precision deterioration, increased springback and wall camber, and difficult production of complex product shapes, etc., and achieves delayed fracture resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

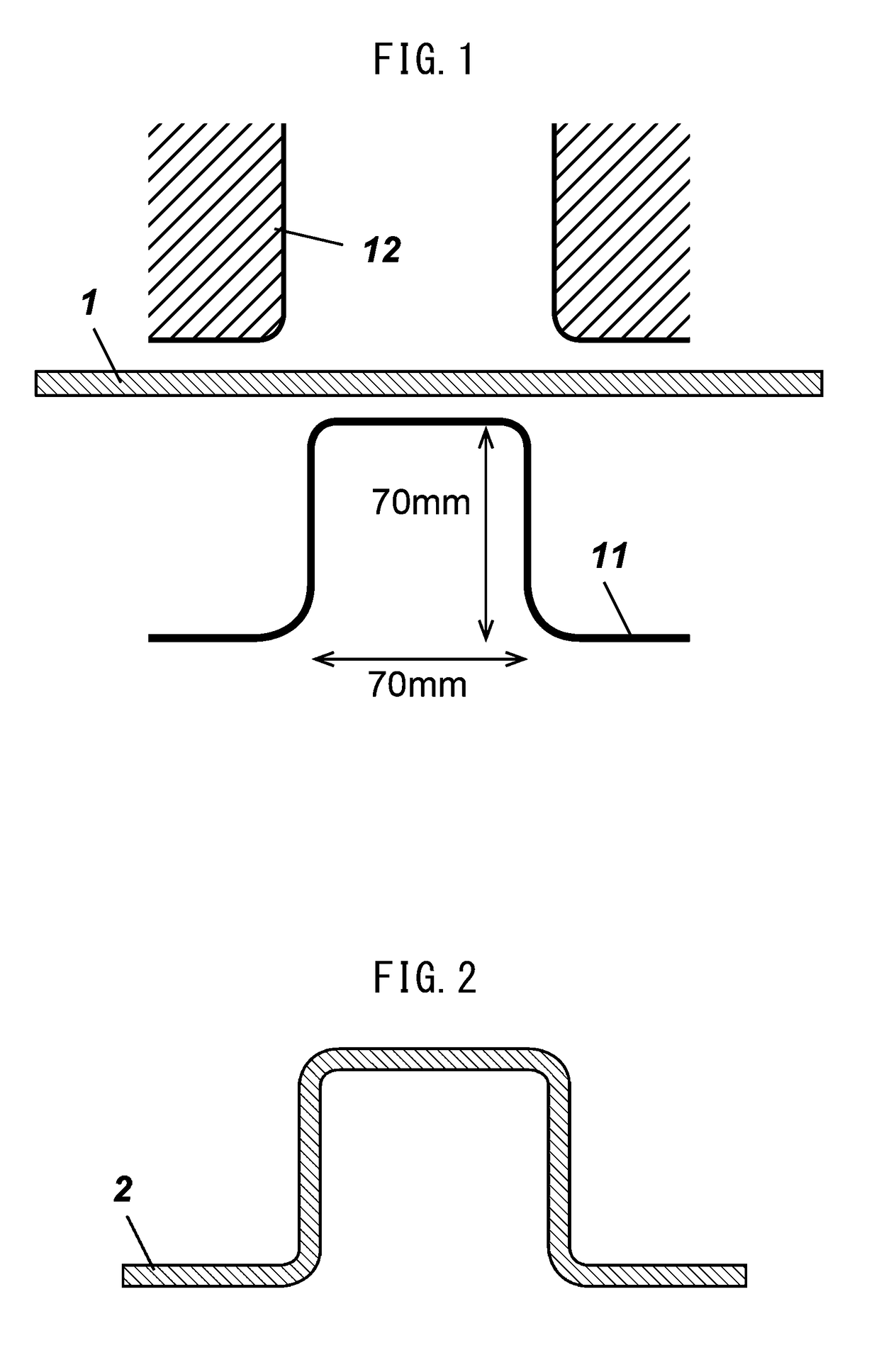

[0098]Below, examples will be used to more specifically explain the present invention, but the present invention is not limited to these examples.

[0099]Steel having each of the chemical compositions shown in Table 1 was smelted in a test converter and continuously cast by a continuous casting test machine to obtain a width 1000 mm, thickness 250 mm slab. Here, at the conditions shown in Table 2, the heating temperature of the molten steel and amount of casting of molten steel per unit time were adjusted.

[0100]The cooling speed of the slab was controlled by changing the amount of water at the secondary cooling spray zone. Further, the center segregation reduction treatment was performed at the end part of solidification using a roll mill to softly reduce the thickness by a gradient of 1 mm / m and discharge the concentrated molten steel of the final solidified part. In some slabs, after that, a soaking treatment was performed under conditions of 1250° C. and 24 h.

TABLE 1SteelChemical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com