High-strength thermal forming martensitic steel

A martensitic steel, hot forming technology, applied in the field of alloy steel, to achieve the effect of reduced hydrogen-induced delayed fracture sensitivity and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

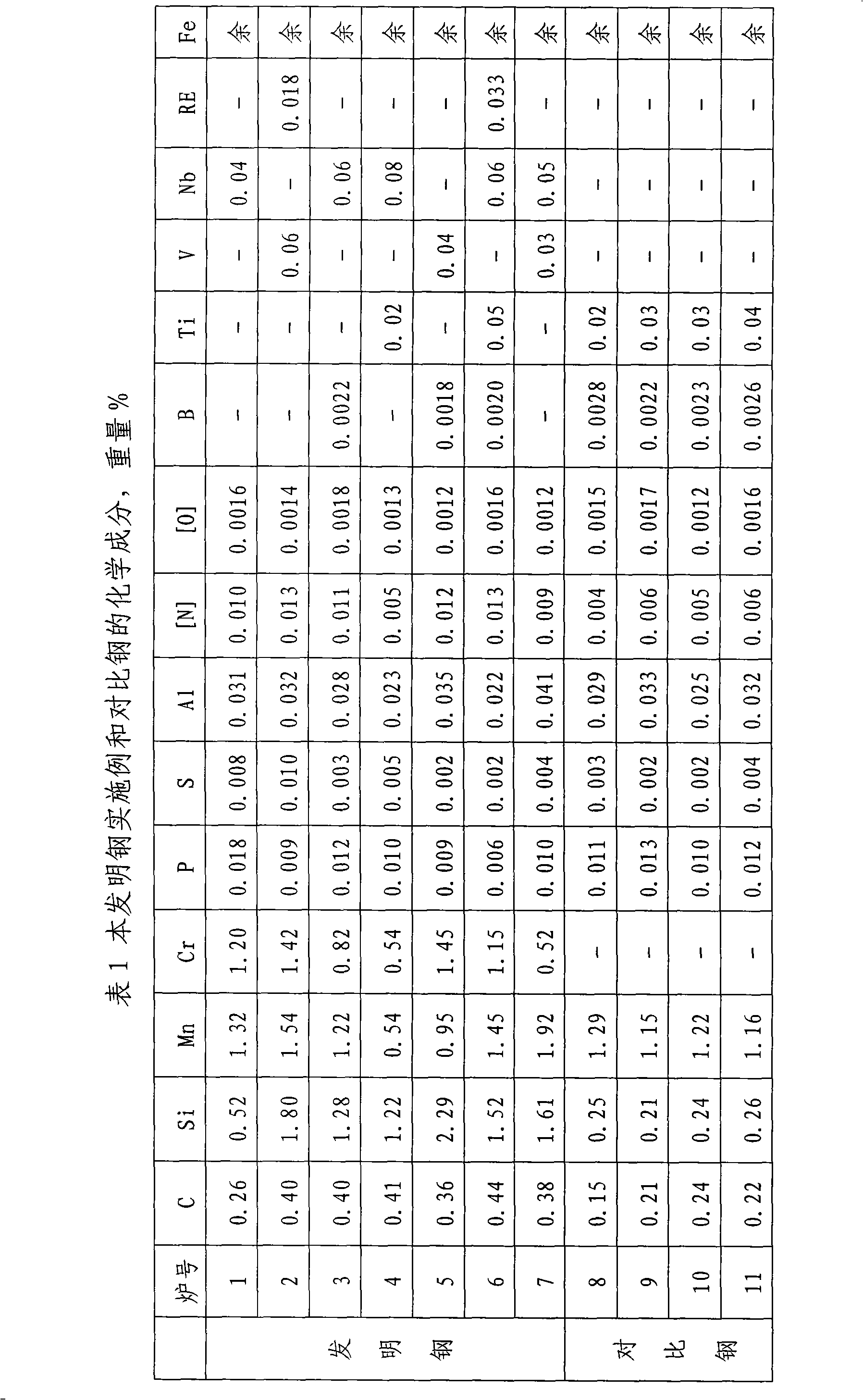

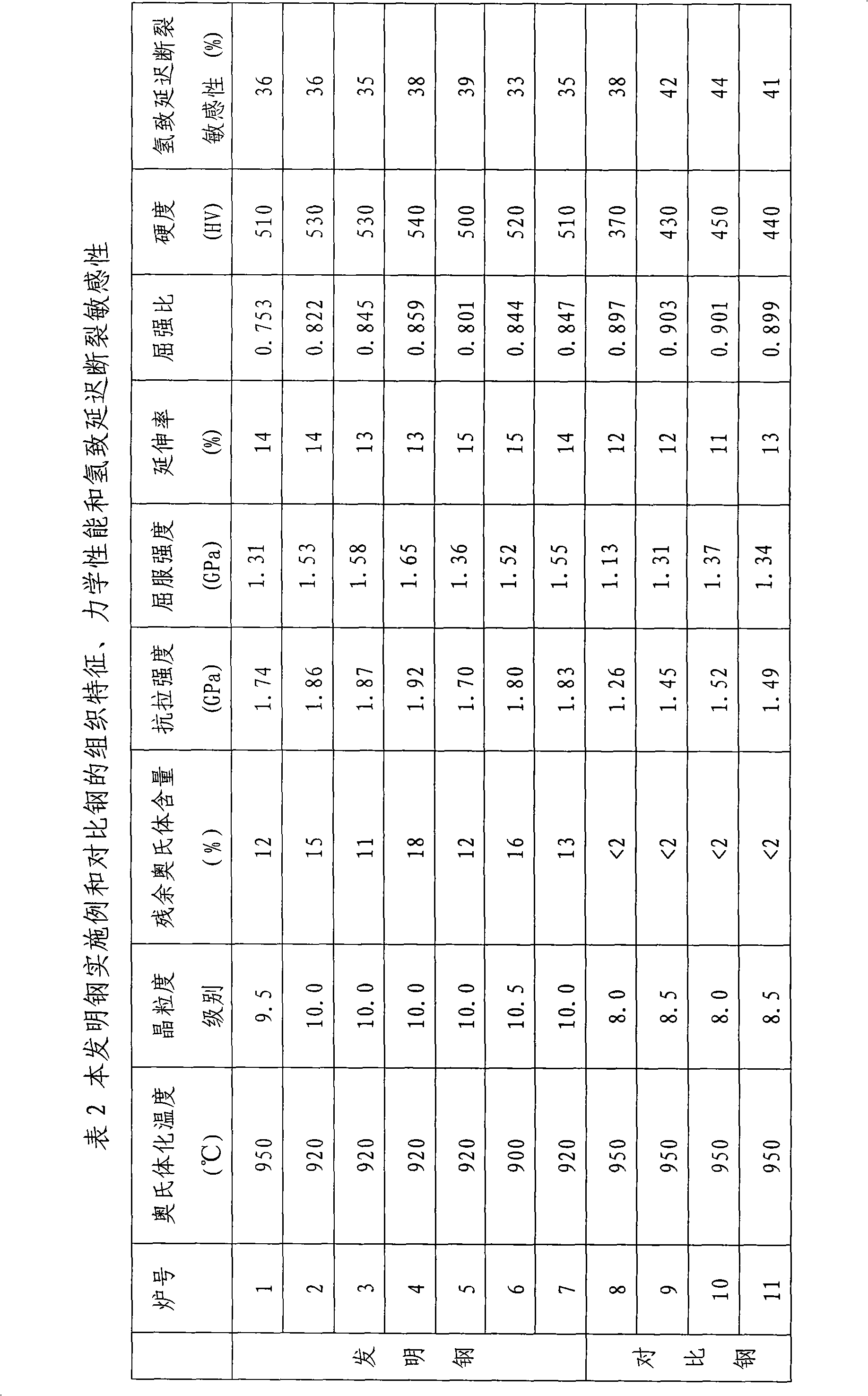

[0028] Material preparation: According to the above-designed chemical composition range, 5 furnaces (heat number 1-5) of the invention steel and 2 furnaces of comparative steel (heat number 8-9) were smelted on a 500kg induction furnace, in addition to 2 furnaces (heat number 8-9). Heat 6-7) The steel of the present invention produced by electric furnace (EAF) + refining (LF+VD) smelting + die casting + hot continuous rolling process and 2 furnaces of comparative steel (heat number 10-11), the specific chemical composition is as follows Table 1 shows. The test material was finally processed into a 1.8mm thin plate (for thermoforming) and a bar with a diameter of φ12mm (used to determine the mechanical properties and hydrogen induced delayed fracture sensitivity).

[0029] Tensile mechanical properties: After rough machining the bar with a diameter of φ12mm, it is austenitized at 900-950℃×30 minutes. The invention steel is quenched to Ms-200℃ and then slowly cooled. The comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com