High strength thin steel sheet having high hydrogen embrittlement resisting property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0050] The first high strength thin steel sheet according to the present invention comprises higher than 0.10 and up to 0.25% of C (contents of components given in terms of percentage in this patent application all refer to percentage by weight), 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, 0.15% or less P, 0.02% or less S, 1.5% or less (higher than 0%) of Al, 1.0% or less (higher than 0%) of Mo and 0.1% or less (higher than 0%) of Nb, with balance of iron and inevitable impurities, and

[0051] the metal structure comprises:

[0052] 1% or more residual austenite;

[0053] 80% or more in total of bainitic ferrite and martensite; and

[0054] 9% or less (may be 0%) in total of ferrite and pearlite in terms of the proportion of area to the entire structure, and

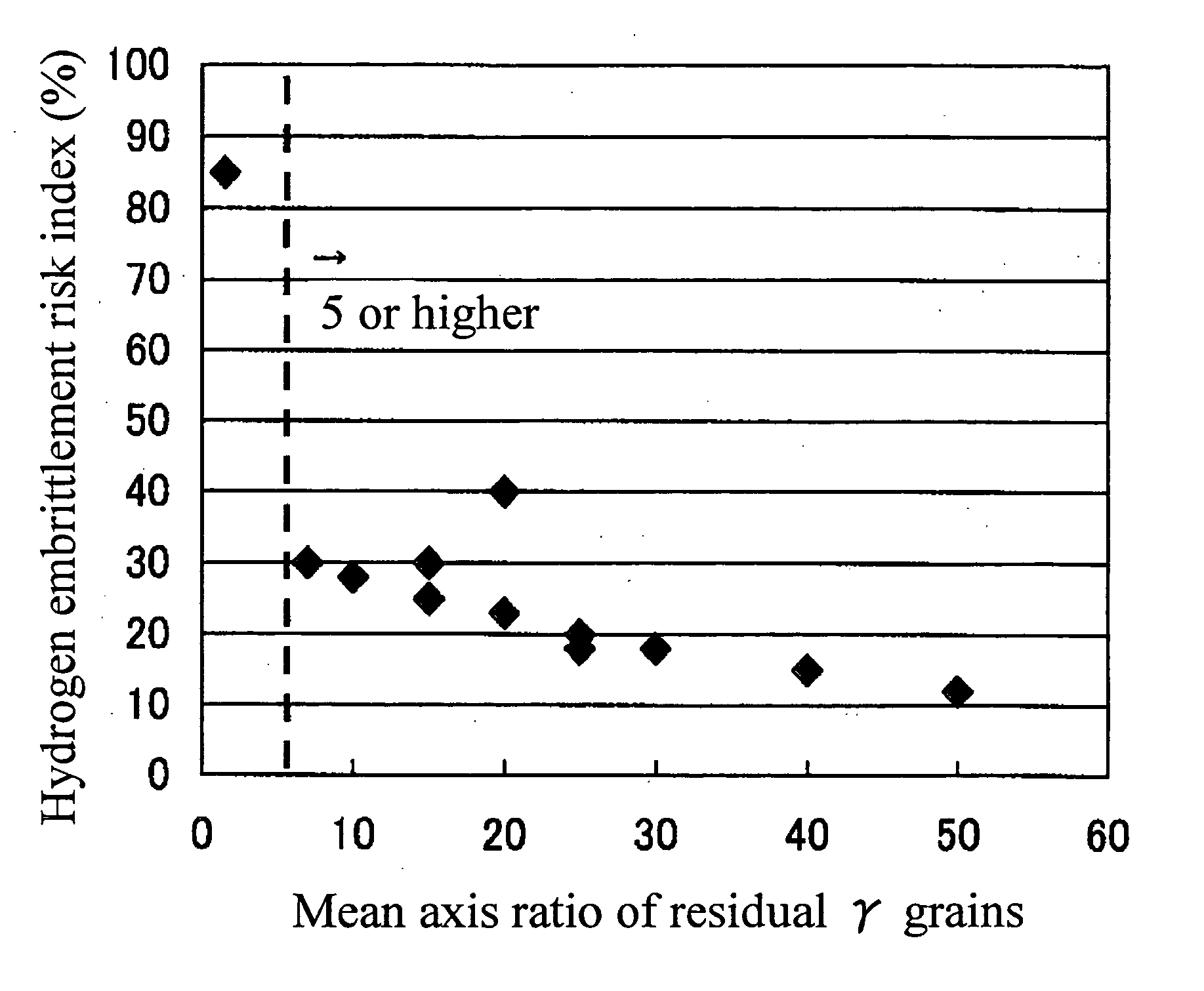

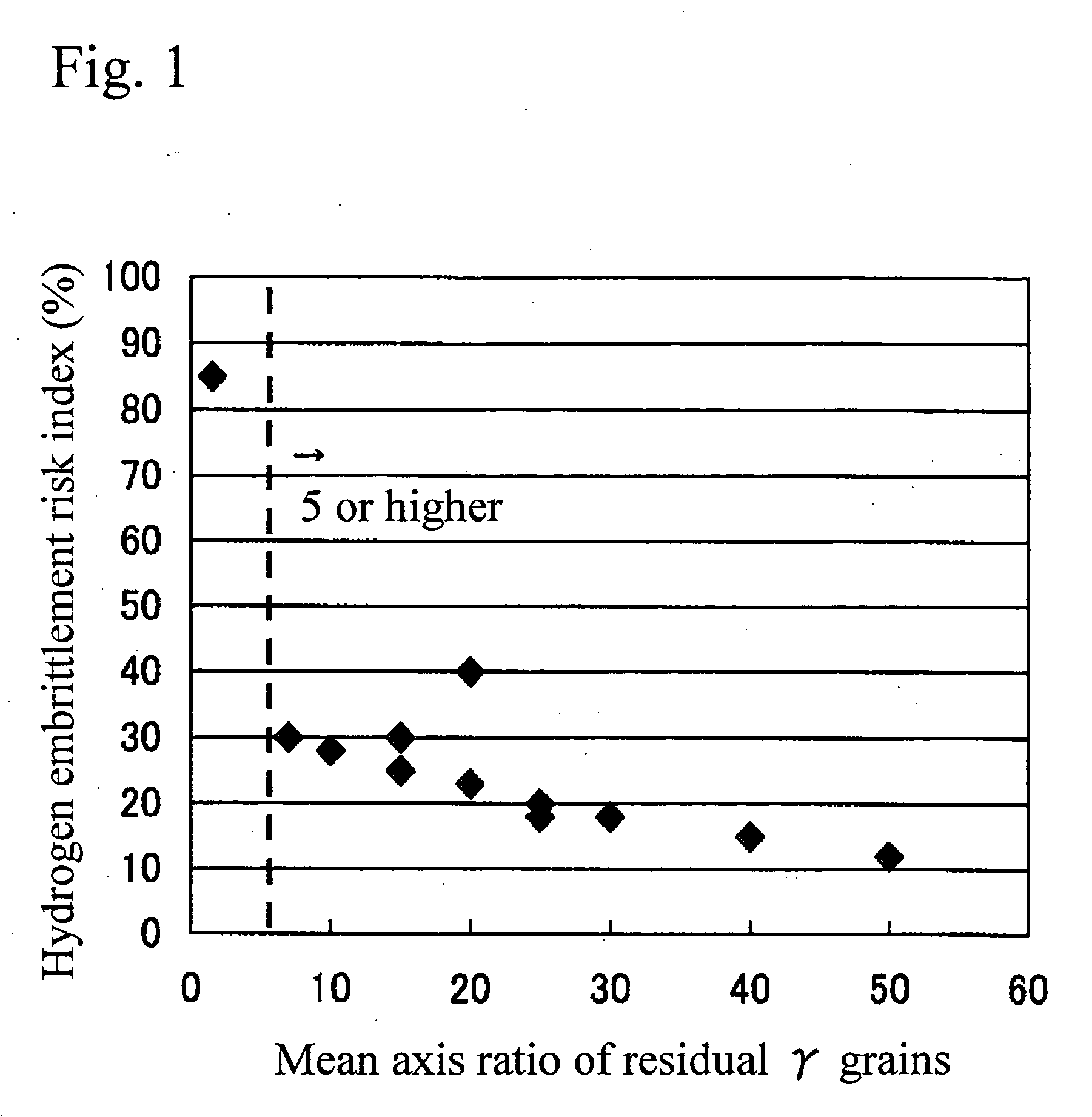

[0055] the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher.

(1% or more residual austenite in the area proportion to the entire structure)

[0056] It is necessary that the metal contains 1% or more res...

second embodiment

[0110] The second high strength thin steel sheet according to the present invention comprises:

[0111] C: higher than 0.10 up to 0.25%; Si: 1.0 to 3.0%; Mn: 1.0 to 3.5%; P: 0.15% or less; S: 0.02% or less; and Al: 1.5% or less (higher than 0%) in terms of percentage by weight, with balance of iron and inevitable impurities, wherein the metal structure comprises:

residual austenite; 1% by area or more in proportion to the entire structure;

while the mean axis ratio (major axis / minor axis) of said residual austenite grains is 5 or higher;

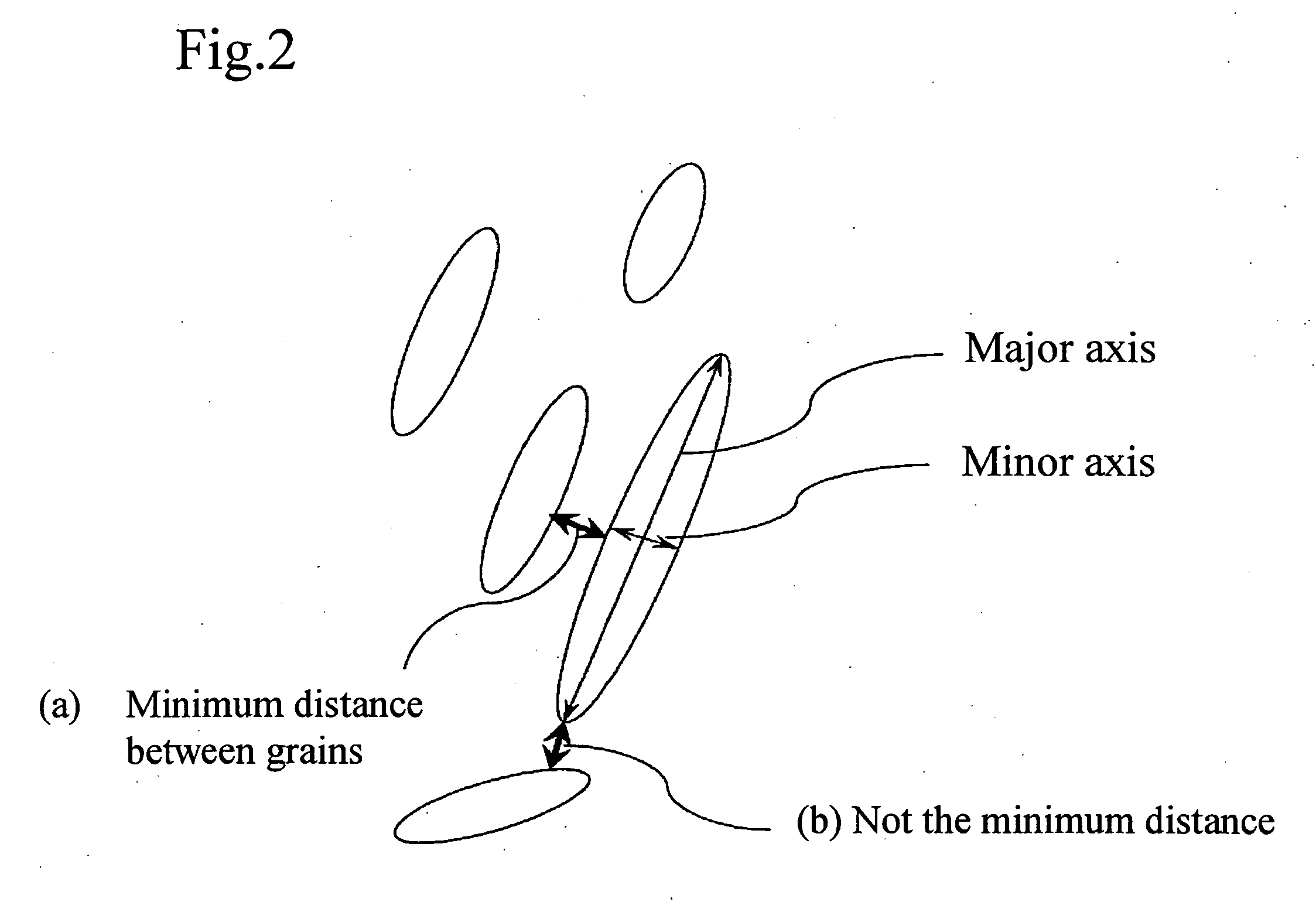

mean length of minor axes of said residual austenite grains is 1 μm or less; and

[0112] a minimum distance between said residual austenite grains is 1 μm or less; and the steel has tensile strength of 1180 MPa or higher. The structure may further contain 80% or more bainitic ferrite and martensite in total and / or 9% or less (may be 0%) ferrite and pearlite in total, and the structure may not contain them.

[0113] The reason why the above requirement...

example 1

[0118] Sample steels A-1 through Y-1 having the compositions described in Table 1 were melt-refined in vacuum to make test slabs. The slabs were processed in the following procedure (hot rolling→cold rolling→continuous annealing) thereby to obtain hot-rolled steel plates measuring 3.2 mm in thickness. The steel plates were pickled to remove scales from the surface and then cold rolled so as to reduce the thickness to 1.2 mm.

Starting temperature (SRT): Held at a temperature between 1150 and 1250° C. for 30 minutes.

Finishing temperature (FDT): 850° C.

Cooling rate: 40° C. / s

Winding-up temperature: 550° C.

Rolling ratio: 50%

[0119] Each steel specimen was kept at a temperature of A3 point+30° C. for 120 seconds, then cooled in air at a mean cooling rate of 20° C. / s to temperature T0 shown in Table 2, and was kept at T0 for 240 seconds, followed by air-assisted water cooling to the room temperature.

[0120] No. 116 shown in Table 2 was made by heating a cold-rolled steel sheet to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com