Large scale preparation method of high-nickel cobalt-free precursor and cathode material

A large-scale preparation and cathode material technology, applied in the field of energy storage materials and electrochemistry, can solve the problems of difficulty in controlling the growth of primary particle crystals, affecting high-temperature cycles and high-temperature storage, poor structural stability and high-temperature stability, etc., to achieve beneficial Large-scale market promotion, improved thermal stability, high temperature cycle and high temperature storage excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

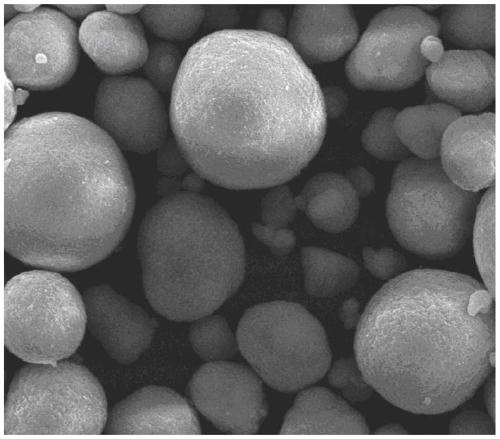

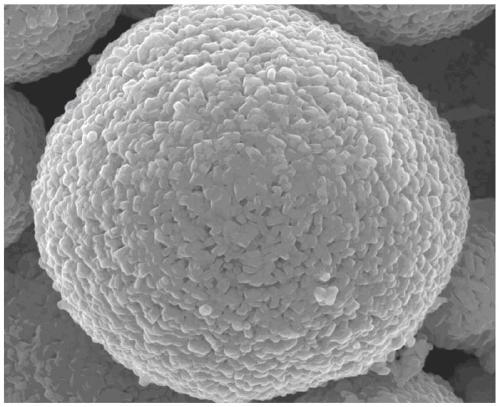

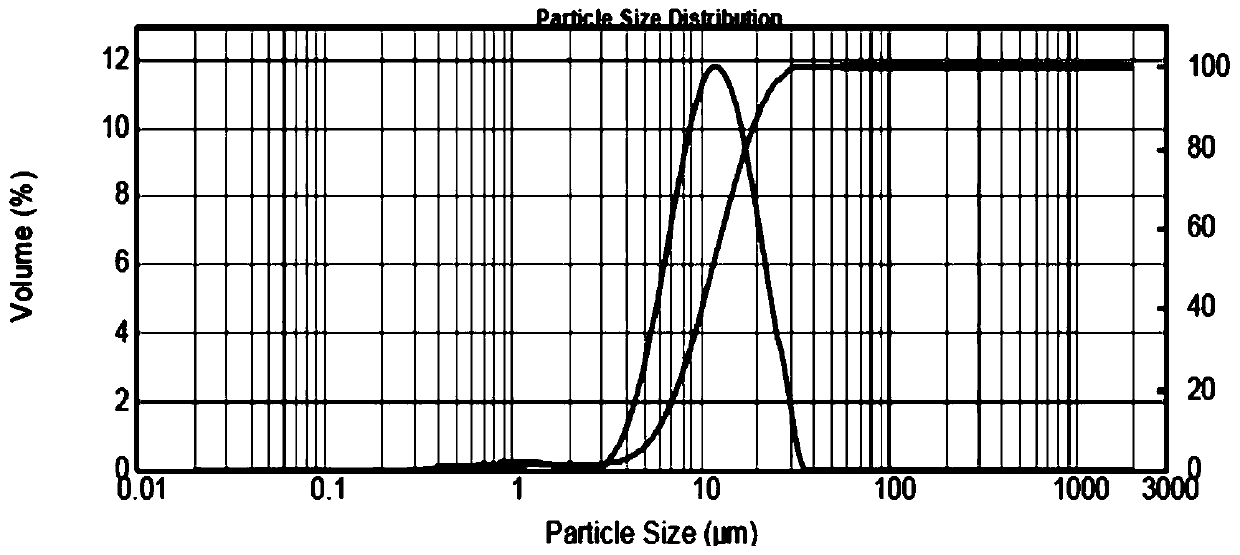

[0055] The present invention is a large-scale preparation method of a high-nickel and cobalt-free precursor and positive electrode materials. In the case, the large-scale preparation of a high-nickel and cobalt-free precursor includes:

[0056] A high-nickel cobalt-free cathode material precursor, the high-nickel cobalt-free precursor such as the general formula Ni x m y N z (OH) 2 Shown, where M = one of (Al, Ba, Pr, Ce, Cr, Mn, Ti, Sr, Zr, Ge, Er, W), N = (La, Nd, Dy, Eu, Nb, Mg , one of Yb, Lu, Sn, Mo), x+y+z=1, 0.6≤x<1, 0≤y<0.5, 0≤z<0.5.

[0057] Preferred Example 1: The high-nickel cobalt-free cathode material precursor such as the general formula Ni 0.90 Ti 0.09 Mg 0.11 (OH) 2 As shown, that is, x=0.90, y=0.09, z=0.11.

[0058] Preferred Example 2: The precursor of the high-nickel and cobalt-free positive electrode material is such as the general formula Ni 0.88 Mg 0.12 (OH) 2 As shown, that is, x=0.88, y=0.12, z=0.

[0059] Preferred Example 3: The precursor...

Embodiment 1

[0083] A large-scale preparation method of a high-nickel-cobalt-free precursor and anode material, including (1) a high-nickel-cobalt-free cathode material precursor and (2) a high-nickel-cobalt-free cathode material, the large-scale preparation of both.

[0084] Wherein (1) comprises the following steps:

[0085] 1) Sodium hydroxide and ammonia water are prepared into a reaction bottom solution with pH=11 and ammonia concentration of 0.3mol / L; sodium hydroxide is prepared into 2.0mol / L sodium hydroxide solution; ammonia water is prepared into 2.4mol / L Ammonia solution; the inorganic salts of nickel, aluminum and magnesium are dissolved in deionized water after deoxidation to prepare a mixed solution of inorganic salts with a total concentration of 2.5mol / L, wherein the molar ratio of nickel, cobalt and manganese is 0.94: 0.045:0.015;

[0086] 2) Pour the reaction bottom liquid of step 1) into the reaction kettle, stir and pass nitrogen protection, and heat up; the stirring s...

Embodiment 2

[0099] A large-scale preparation method of a high-nickel-cobalt-free precursor and anode material, including (1) a high-nickel-cobalt-free cathode material precursor and (2) a high-nickel-cobalt-free cathode material, the large-scale preparation of both.

[0100] Wherein (1) comprises the following steps:

[0101] 1) Sodium hydroxide and ammonia water are prepared into a reaction bottom solution with pH=11 and ammonia concentration of 0.3mol / L; sodium hydroxide is prepared into 2.0mol / L sodium hydroxide solution; ammonia water is prepared into 2.4mol / L Ammonia solution; dissolving inorganic salts of nickel and strontium in deionized water after deoxidization to prepare a mixed solution of inorganic salts with a total concentration of 2.0mol / L, wherein the molar ratio of nickel and strontium is 0.96:0.04;

[0102] 2) Pour the reaction bottom liquid of step 1) into the reaction kettle, stir and pass nitrogen protection, heat up; the stirring speed is set to 250rpm, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com